Efficient electromechanical rotor pump

A rotor pump, integrated technology, used in rotary piston pumps, pumps, mechanical equipment and other directions, can solve the problems of reduced pump efficiency and service life, wear of sliders and sliders, high noise, etc., to improve service life, increase Structural strength, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

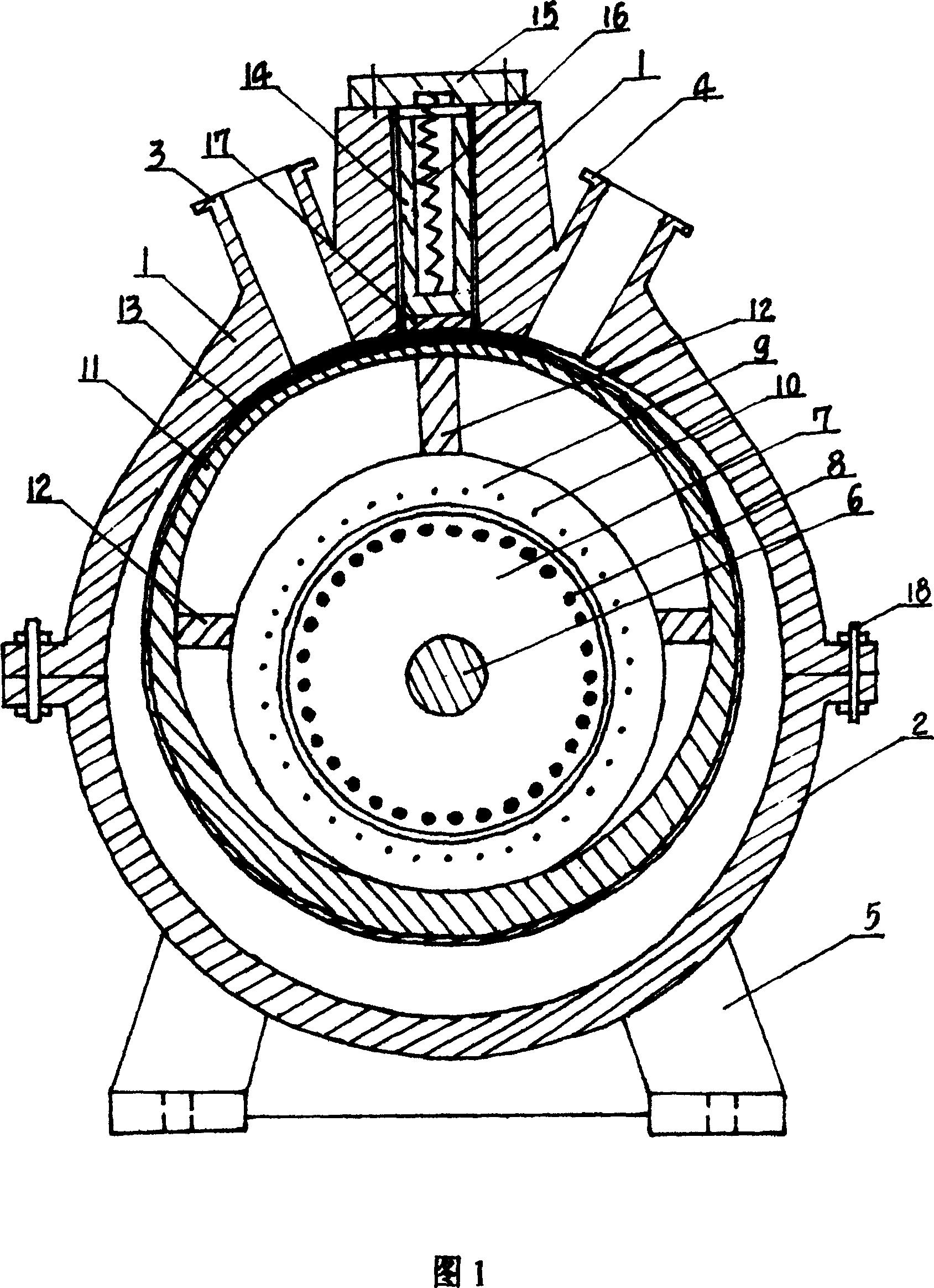

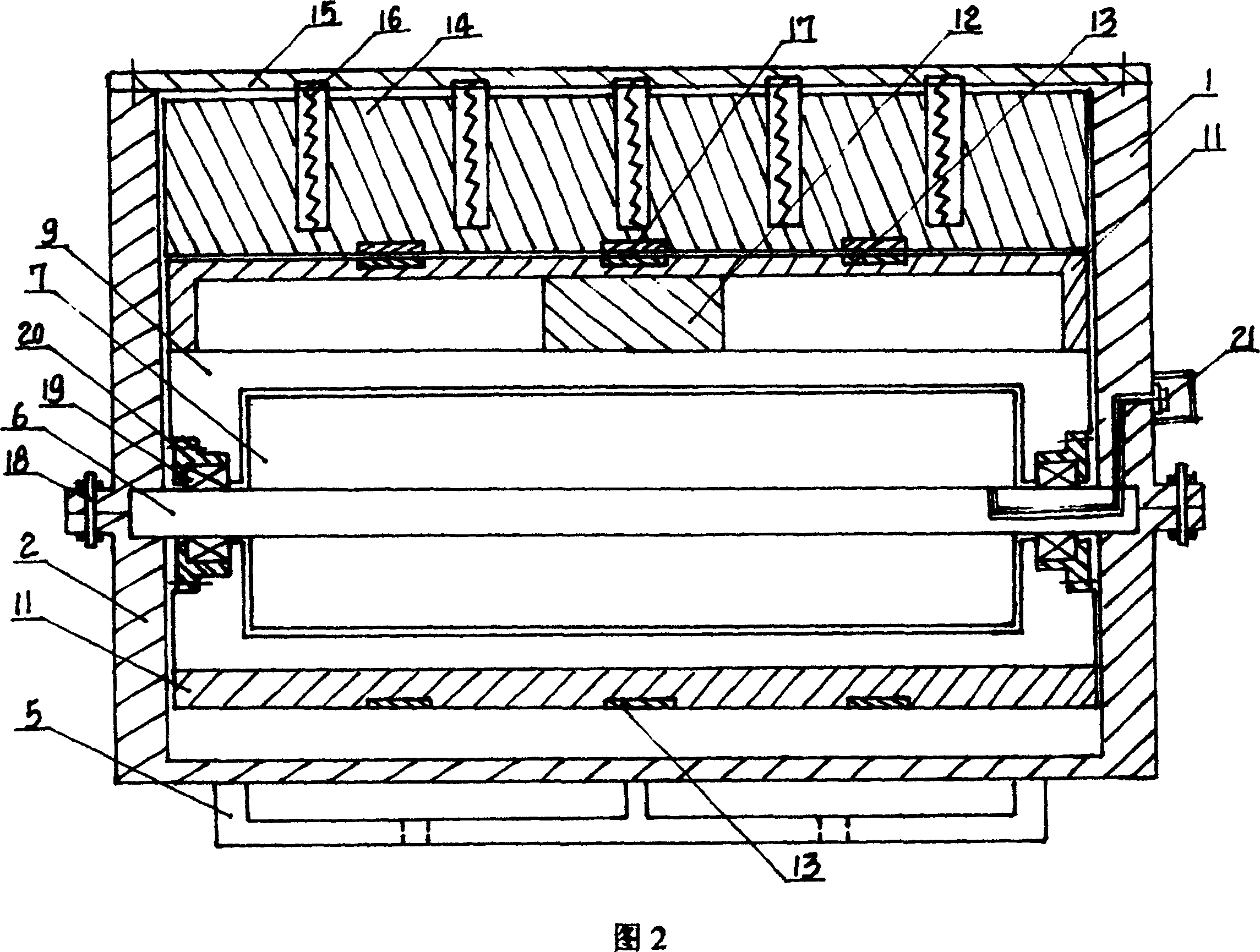

[0020] In Fig. 1 and Fig. 2, a rotor pump housing assembly, a stator assembly, an outer rotor assembly, a movable magnetic partition assembly, a bearing assembly, an outlet pipe and an inlet pipe are provided.

[0021] The rotor pump casing assembly is composed of the upper pump casing 1, the lower pump casing 2 and the pump seat 5, and its function is to form a sealed cylindrical space and support the entire pump body. The upper pump casing 1 and the lower pump casing 2 are both made of cast steel, and they are fixed together by bolts 18. The function of the upper pump casing 1 and the lower pump casing 2 is to form the pump body on the one hand and install the water pump. Each component, on the other hand, is to form a split-type pump casing structure, so that the various components inside the water pump can be inspected and installed by opening the upper pump casing 1 . The pump seat 5 and the lower pump casing 2 are cast together, and its function is exactly to support the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com