Anticounterfeit paper containing sheet material and manufacturing method thereof

A technology of sheet material and manufacturing method, applied in papermaking, textile and papermaking, fiber raw material processing and other directions, can solve the problems of insufficient printing performance and easy forgery of anti-counterfeiting paper, and achieve the effect of not affecting the printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

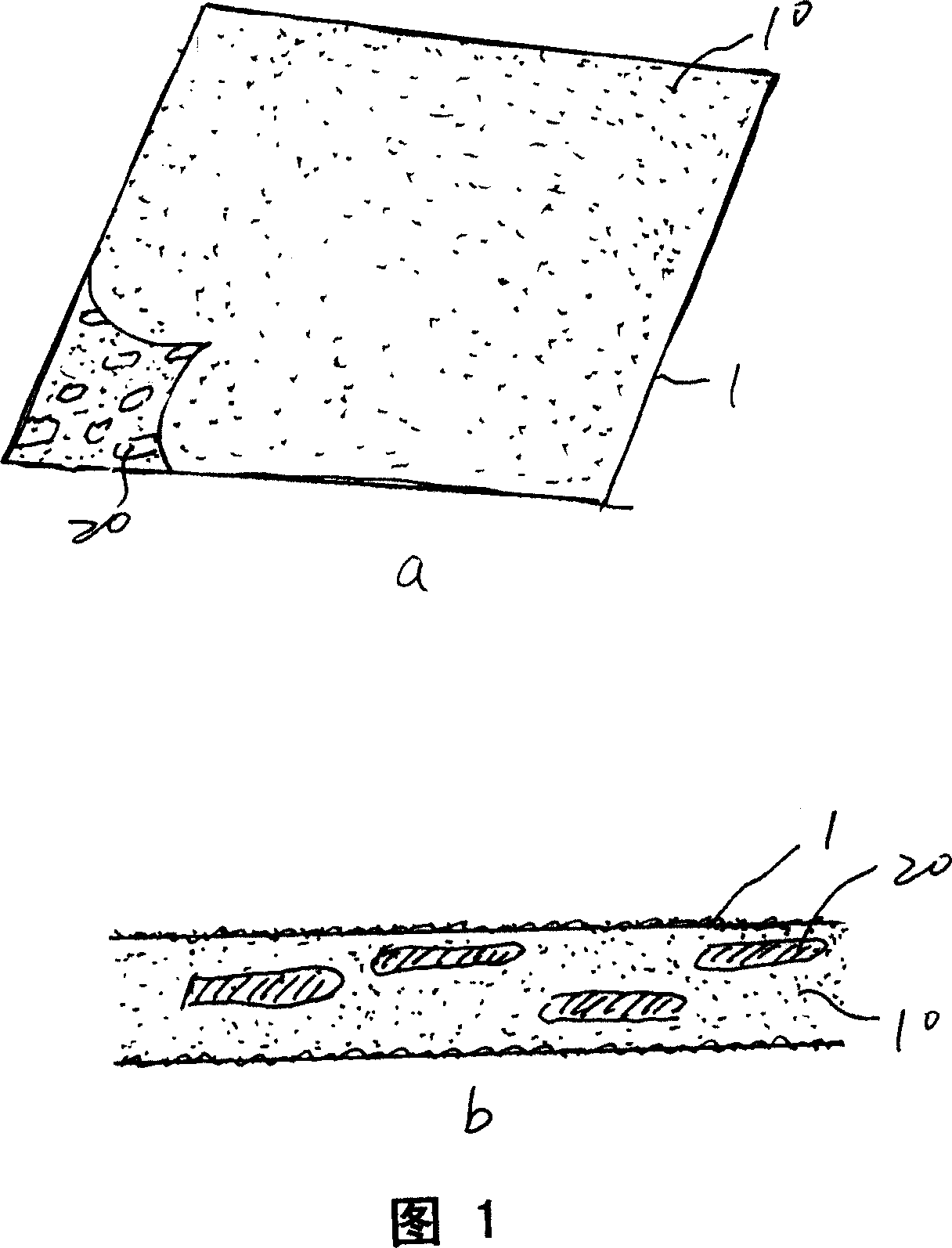

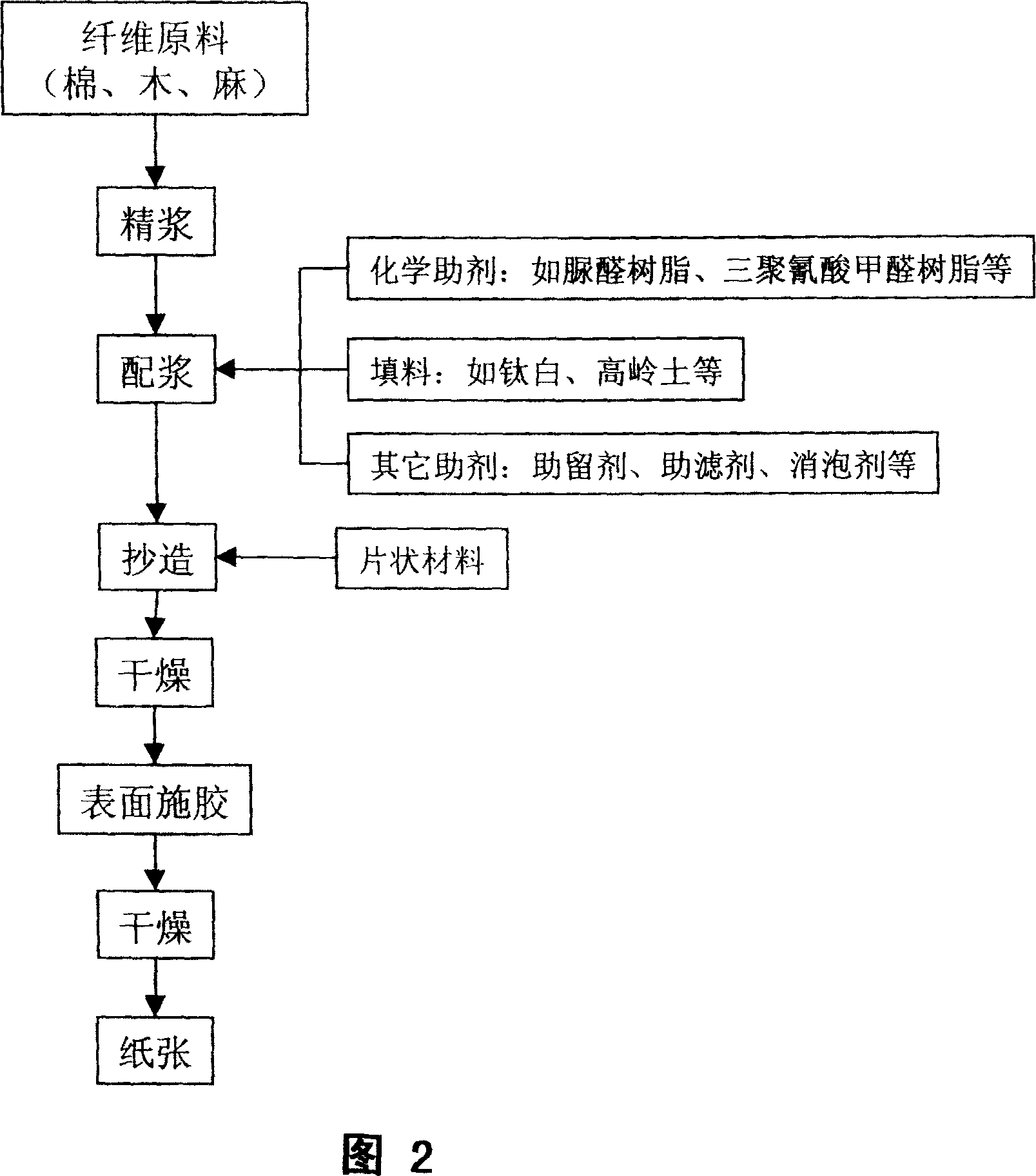

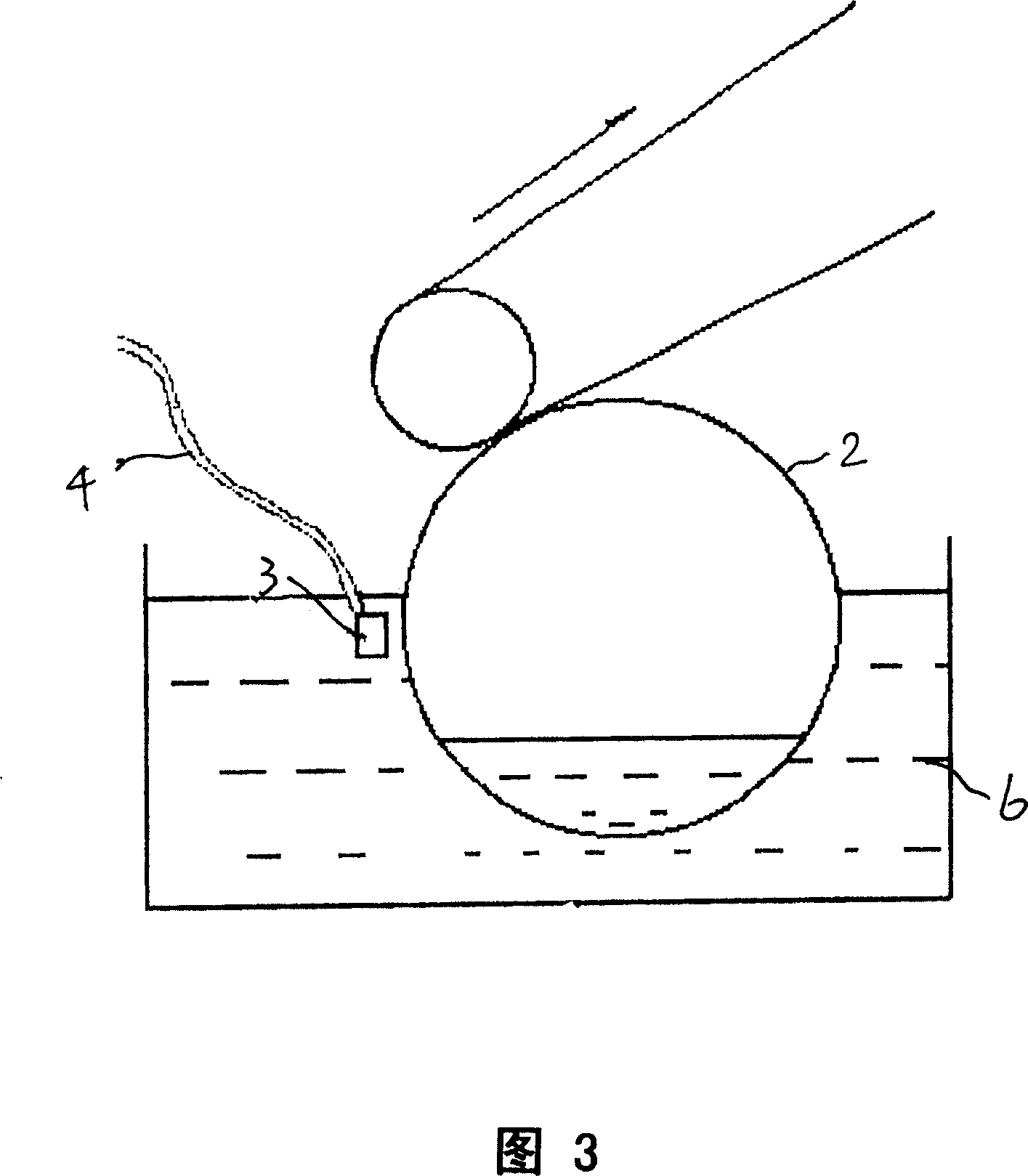

[0032] In this embodiment, during the copying step, the square plastic material sheet material with a side length of 0.2 mm and a thickness of 0.01 mm is dispersed with water at a concentration of 0.01% to form a uniform water dispersion, and the diameter is passed through a plastic material with a diameter of 1.2 cm. At a flow rate of 1500ml / min, the pipeline is released into the slurry in the mesh tank through the release port. The release port is 3.0cm lower than the surface of the liquid level in the network tank. With the forming of the wet paper sheet, the sheet material is embedded in the paper by the pulp fiber.

Embodiment 2

[0034] In this embodiment, during the papermaking step, the circular paper sheet material with an area of 6.0 square millimeters and a thickness of 0.03 mm is dispersed with water at a concentration of 0.2% to form a uniform water dispersion, and passed through a diameter of 1.6 cm. The plastic pipe is released into the mesh tank slurry through the release port at a flow rate of 2000ml / min. The release port is 2.0cm below the liquid level surface of the network tank. With the forming of the wet paper sheet, the sheet material is buried into the paper by the pulp fiber.

Embodiment 3

[0036] In this embodiment, during the copying step, an irregular metal sheet material with an area of 3.0 square millimeters and a thickness of 0.075 mm is dispersed with water at a concentration of 0.5% to form a uniform water dispersion. According to the flow rate of 1200ml / min, the plastic pipe is released into the slurry of the mesh tank through the release port. The release port is 2.0cm below the surface of the liquid level of the network tank. With the forming of the wet paper sheet, the sheet material is embedded in the paper by the pulp fiber .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com