Control method and device for molding terminal linear scanning molding for 3D printer

A 3D printer and molding device technology, applied in the field of 3D printing, can solve problems such as affecting the appearance and accuracy of molding, and reduce product quality, and achieve the effect of improving efficiency and printing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

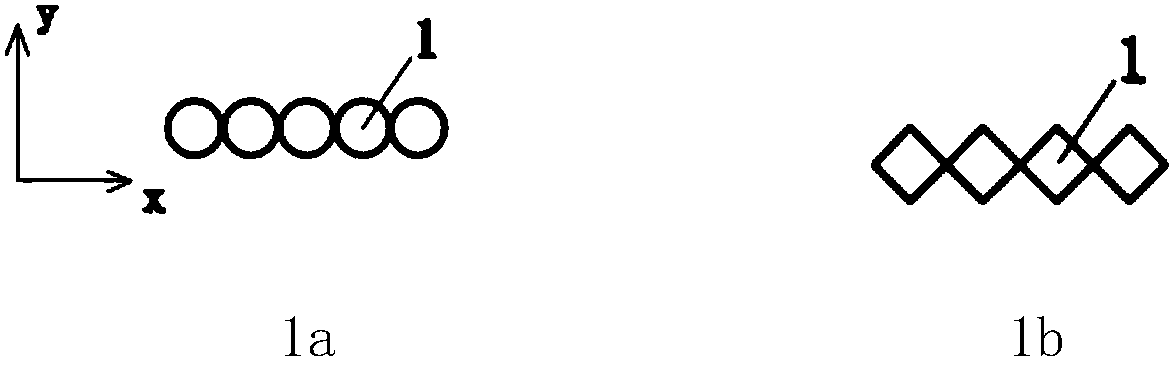

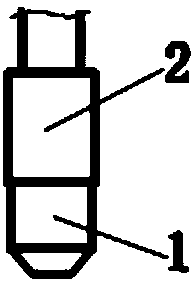

[0038] The specific embodiment of the present invention is as Figures 1 to 2 As shown, a linear extrusion molding device for an extrusion build-up molding 3D printer includes a scanning molding mechanism 1 arranged on the 3D printer. The scanning forming mechanism 1 realizes 3D printing forming through linear extrusion forming. The scanning forming mechanism 1 is arranged on the extrusion accumulation forming type 3D printer, and the scanning forming mechanism 1 is a nozzle.

[0039] The linear extrusion molding device used for the extrusion accumulation molding 3D printer also includes a steering motor 2 . The steering motor 2 is arranged above the scanning forming mechanism 1 and controls its rotation. Steering motor 2 is precisely controlled by digitization. According to printing needs, the steering motor 2 can change the angle between the long side of the scanning forming mechanism 1 and the scanning forming path, thereby changing the scanning forming line width.

[0...

Embodiment 2

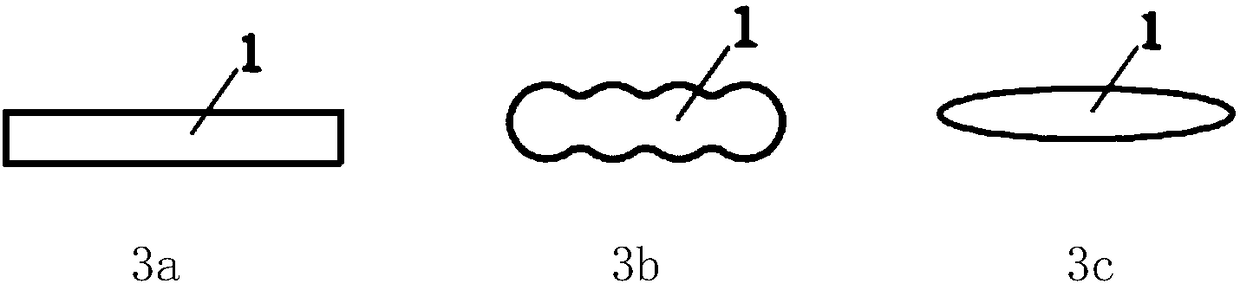

[0046] The difference from Example 1 is that, as image 3 As shown, the cross-sectional structure of the discharge channel of the nozzle in this embodiment is a strip structure. The elongated structure can be rectangular, such as image 3 Shown in a; The elongated structure can also be an elongated figure whose edge is an irregular curve; as image 3 Shown in b;, the elongated structure can also be oval, as image 3 as shown in c.

[0047] Wherein, when the cross-sectional structure of the discharge channel is an elliptical nozzle, the width at both ends is narrower than that in the middle, which is suitable for printing areas with corners.

[0048] Such as Figures 4 to 8 As shown, one of the cross-sectional structures is described as a nozzle whose two long sides are parallel to each other and the two ends are semicircular arcs. Of course, the cross-sectional structure of the nozzle can also adopt the method of porous linear arrangement, and its technical effect is basi...

Embodiment 3

[0052] The difference from Example 1 is that, as Figure 9 As shown, in this embodiment, the linear extrusion molding device for the extrusion accumulation molding 3D printer is used in the field of construction, and the printing material 3 is concrete. The scanning forming mechanism 1 is a nozzle.

[0053] In this embodiment, the angle between the discharge direction of the nozzle and the scanning plane is less than 90 degrees, so that the discharge direction is toward the rear of the movement direction, thereby slowing down the concrete (or other heavy printing materials) in the nozzle under the action of gravity. The lowering speed can prevent concrete (or other heavy printing materials) from accidentally falling. The cross-sectional structure of the discharge channel of the nozzle is a long strip structure, which has smaller layer patterns when printing vertical objects such as walls or columns, and is easier to smooth by caulking, reducing the workload of production pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com