Gear unit and method for controlling an internal pressure in the gear unit

An engineering device and internal pressure technology, applied in the direction of gear transmission, components with teeth, infrastructure engineering, etc., can solve the problems of unfavorable connection to the external environment of the piston, can no longer ensure pressure balance, poor stability, etc., to achieve reliability Oil level measurement, easy to detect, and achieve the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

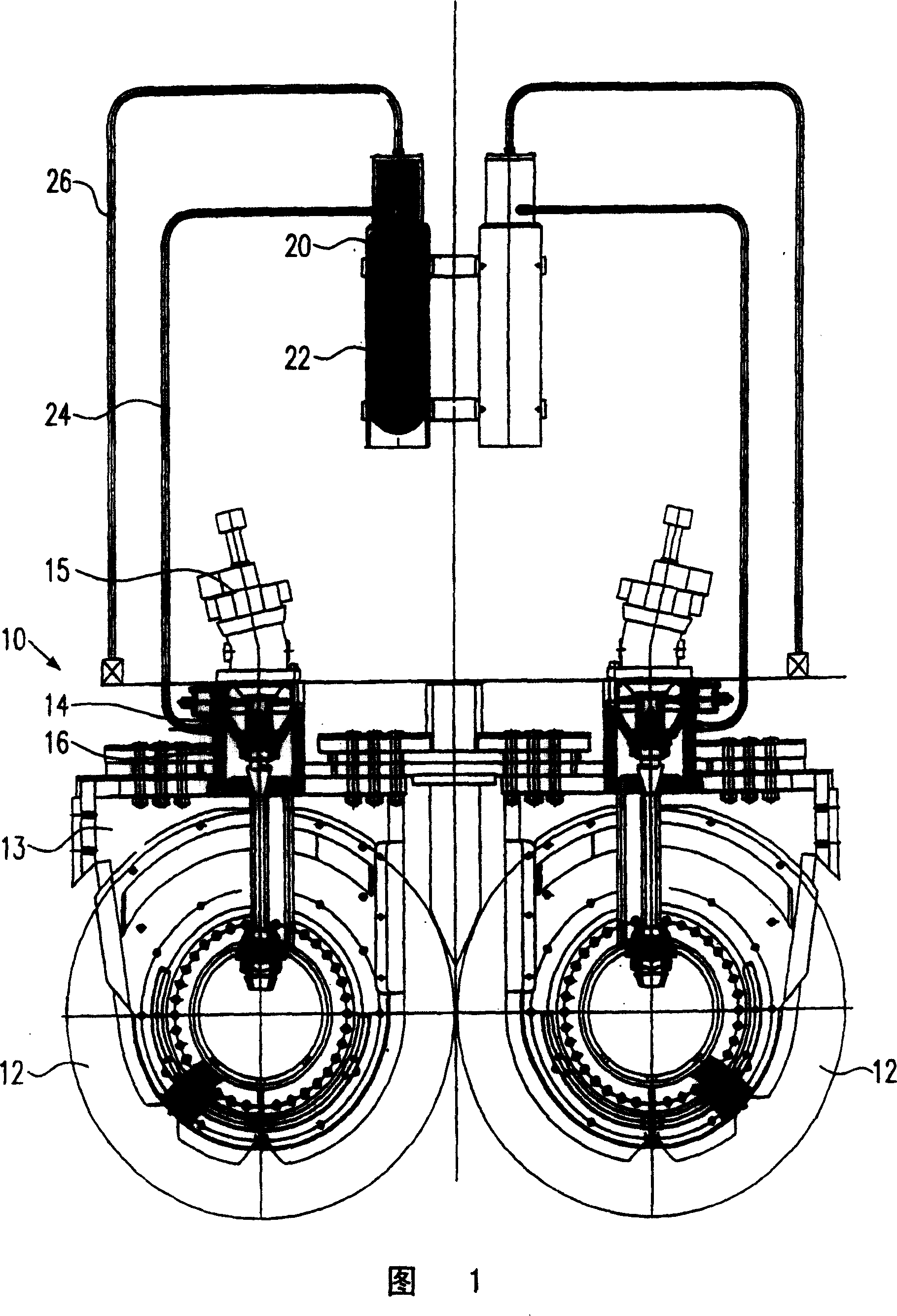

[0028] In FIG. 1 there is shown a trencher 10 designed according to the invention having two cutter wheels 12 on either side of a gear guard 13 . Located on the gear guard 13 is a gear unit 14 according to the invention, which transmits the torque of the hydraulic drive 15 to the cutter wheel 12 . The gear unit 14 extends to the center of the cutter wheel 12, only a part of the gear with teeth is shown. Since the structure of the trencher 10 is symmetrical, the gear structure will only be described below for the structure on the left side of the cutter wheel 12 .

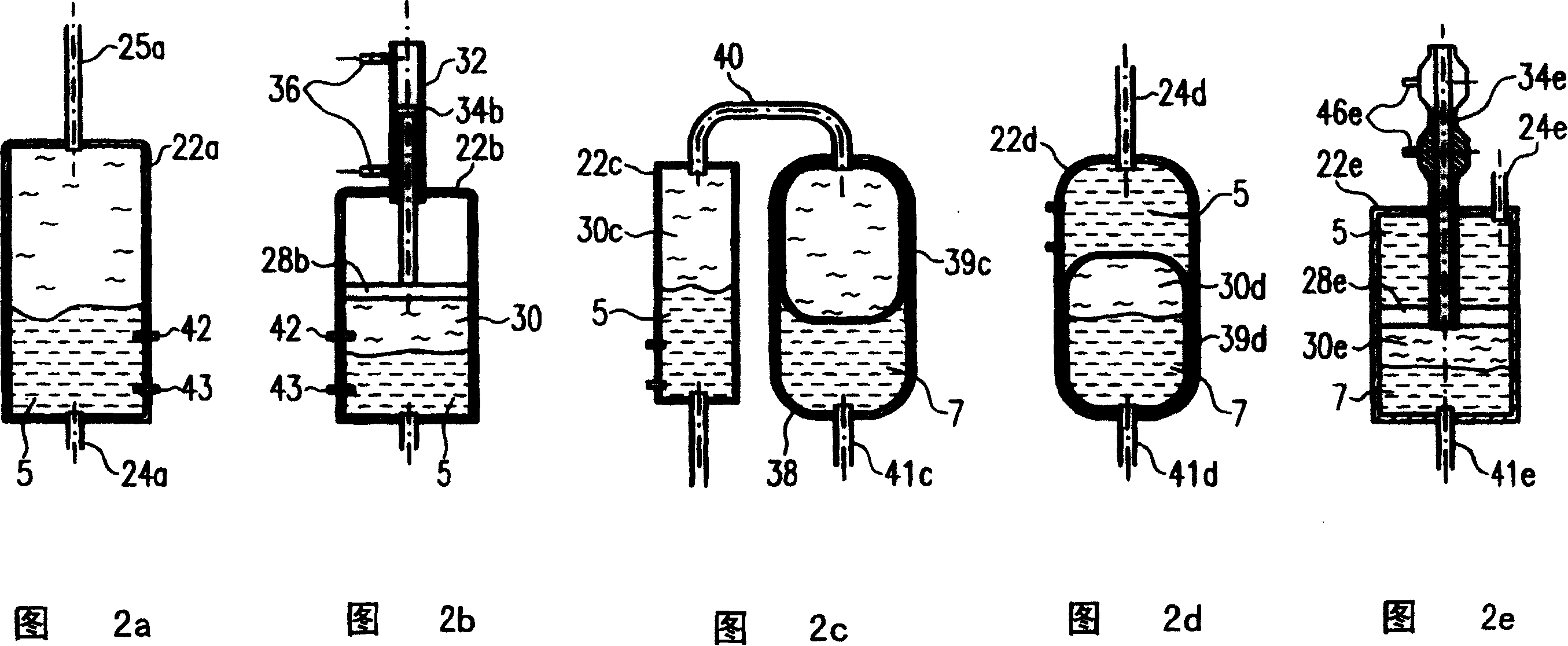

[0029] In order to vary the pressure in the gearbox 16 of the gear unit 14, an active setting device 20 for pressure variation is provided. In the present embodiment, the active setting device 20 has a compensating container 22 which is connected to the interior of the gearbox 16 via a fluid line 24 . In compensation container 22 , the required pressure is generated by means of a control device (not shown here) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com