Surface texture measuring instrument and calibration method thereof

A technology of surface characteristics and correction method, which is applied in the direction of measuring device, mechanical measuring device, mechanical counter/curvature measurement, etc., can solve the problem that more precise correction cannot be performed, and achieve the effect of precise correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

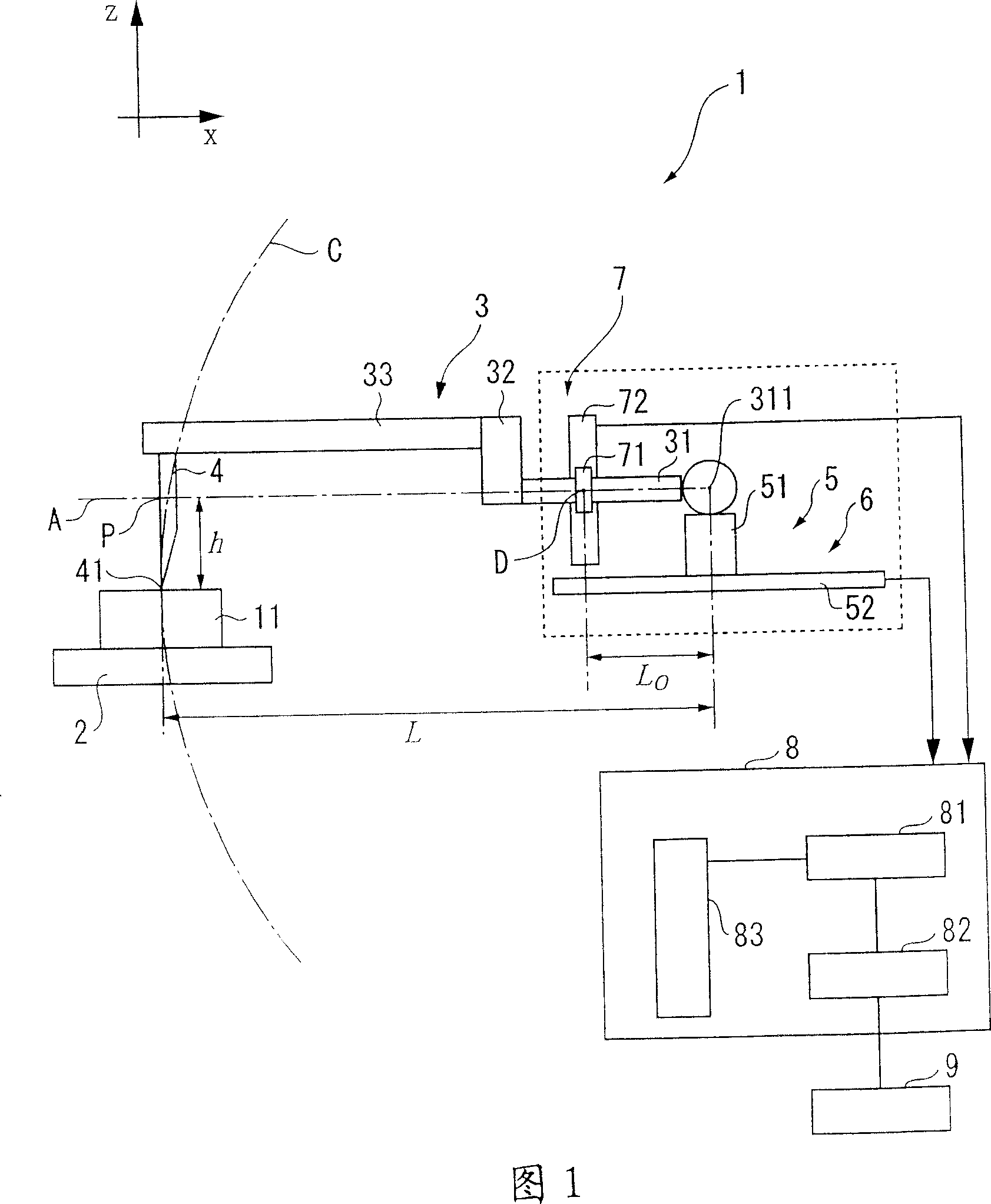

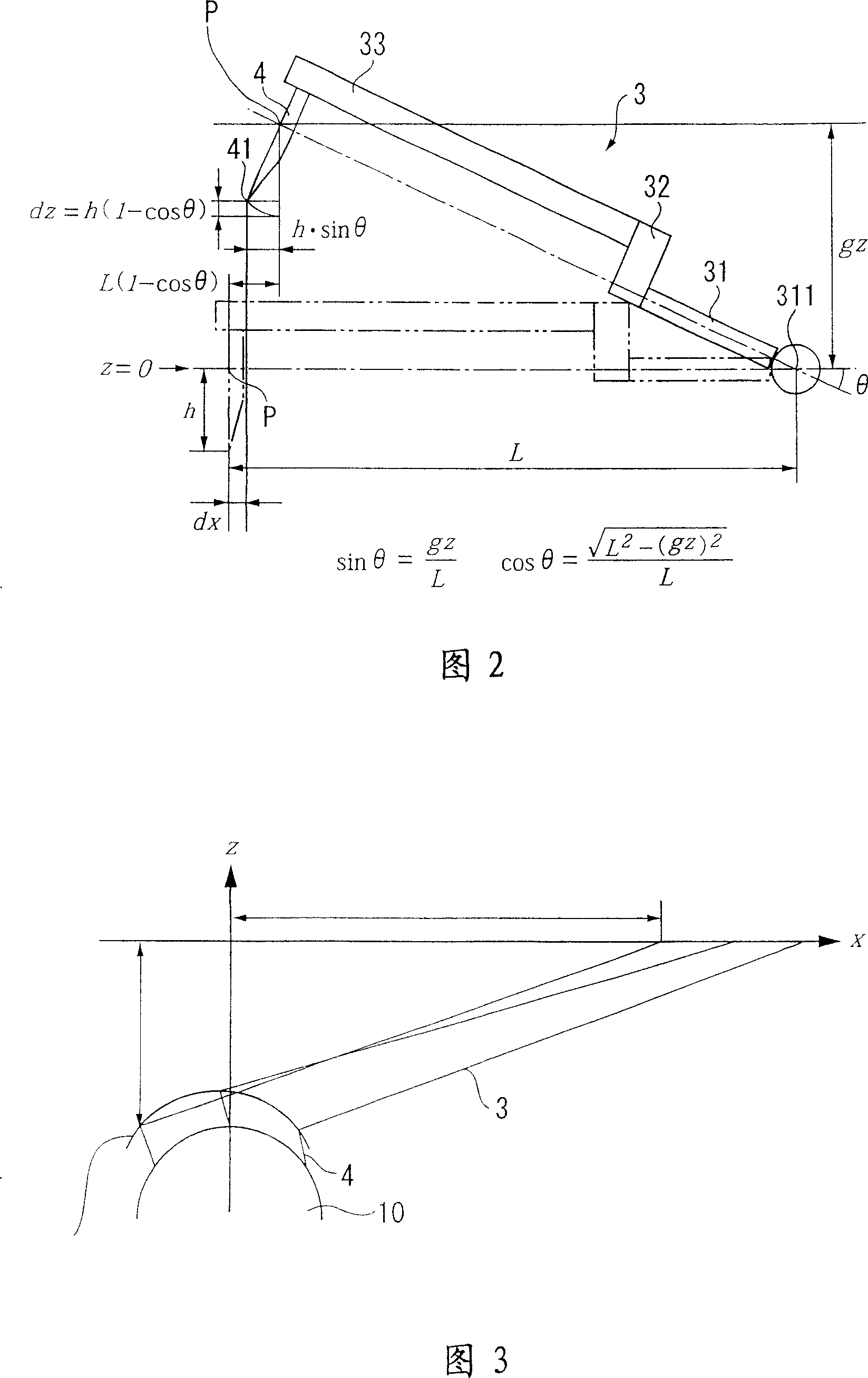

[0070] Next, a method of calibrating the surface characteristic measuring machine 1 of the present invention will be described.

[0071] The calibration method of the surface characteristic measuring machine 1 includes a measurement process, a substitution process, and a calibration process; the measurement process measures a calibration gauge 10 that includes a part of a substantially perfect circle in the cross-sectional shape; The detection result of detection device 6 and above-mentioned the 2nd detection device 7 is substituted into the evaluation formula based on the formula of circle, and the formula of this circle assumes that the central coordinate of perfect circle is (x c ,z c ), the radius is r; this correction process applies the least squares method to the evaluation formula obtained by the substitution process, and corrects each parameter included in the offset.

[0072] In the measurement process, as shown in FIG. 3 , the calibration gauge 10 which can be rega...

no. 2 Embodiment approach

[0094] Next, a second embodiment of the present invention will be described. The basic configuration of the second embodiment is the same as that of the first embodiment, but the second embodiment is characterized in that the least squares method is applied to the arm reference length L as a calibration target in addition to the calibration target of the first embodiment.

[0095] That is, the following least square calculation is performed with respect to the evaluation formula of formula (8).

[0096] Σ ( ∂ fi ∂ x C ) 2 Σ ...

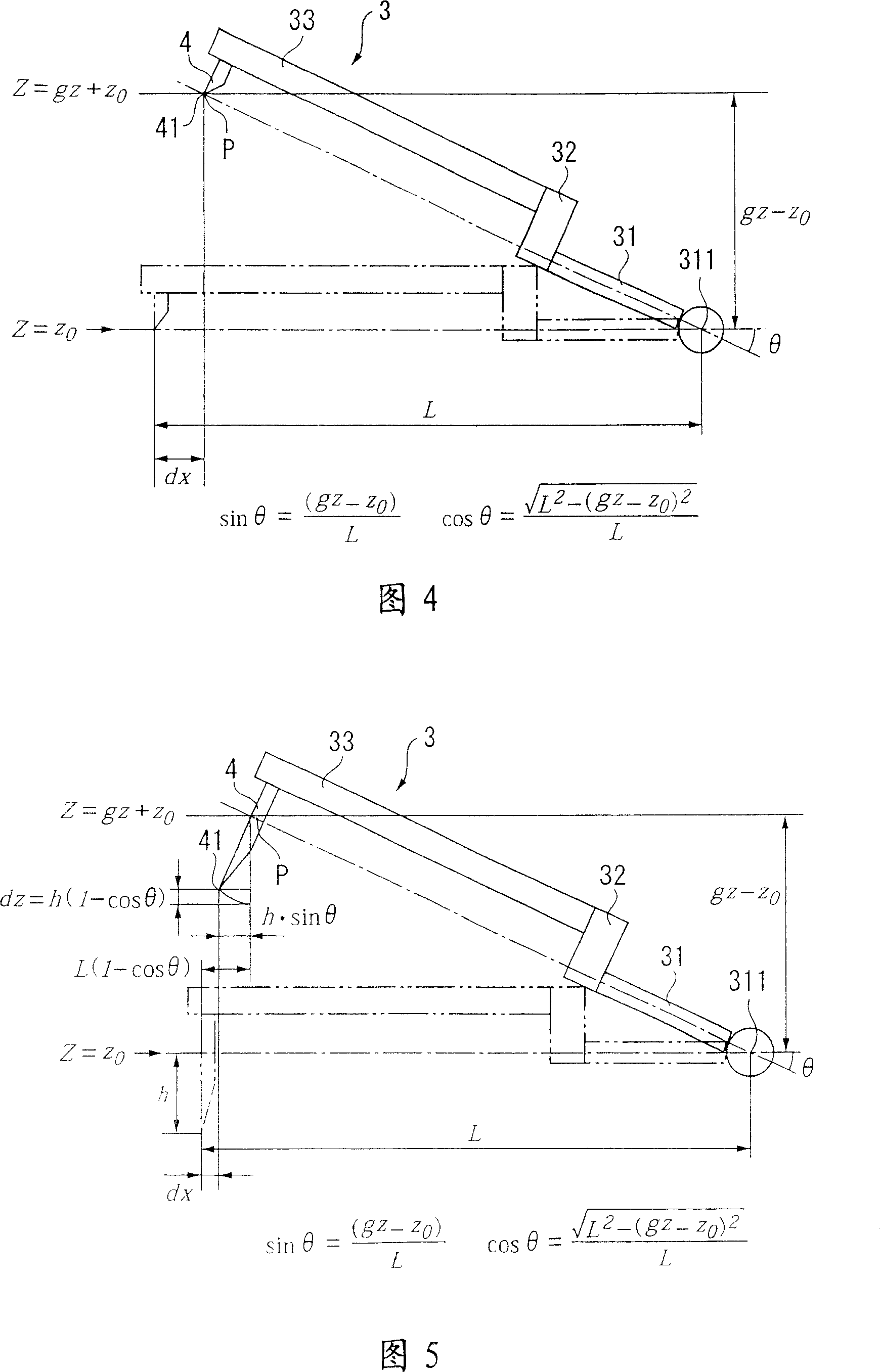

no. 3 Embodiment approach

[0100] Next, a third embodiment of the present invention will be described. The basic configuration of the third embodiment is the same as that of the first embodiment, but the third embodiment is characterized in that the arm reference length L and the zero offset z0 are also the calibration targets in addition to the calibration targets of the first embodiment.

[0101] In the surface characteristic measuring machine 1 according to the third embodiment, as shown in FIG. 4 , the measurement contactor 41 is installed so as to substantially coincide with the reference point. That is, the front end correction amount h is substantially zero, and expressions corresponding to Expressions (5) and (6) as the amount of deviation caused by the swing of the arm 3 are expressed as the following expressions. When calculating the offset in the x direction, the zeroing offset of the second detection device is taken into consideration.

[0102] Wherein, the zeroing offset z0 is the z coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com