Fault filling method and apparatus based on programmable logical device

A technology of fault injection and programming logic, applied in the direction of responding to the generation of errors, etc., can solve the problems of low degree of automation, damage to programmable logic devices, and high cost of fault injection implementation, avoiding electrical damage, and improving controllable management and automation. , The effect of meeting the test requirements of fault-tolerant design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

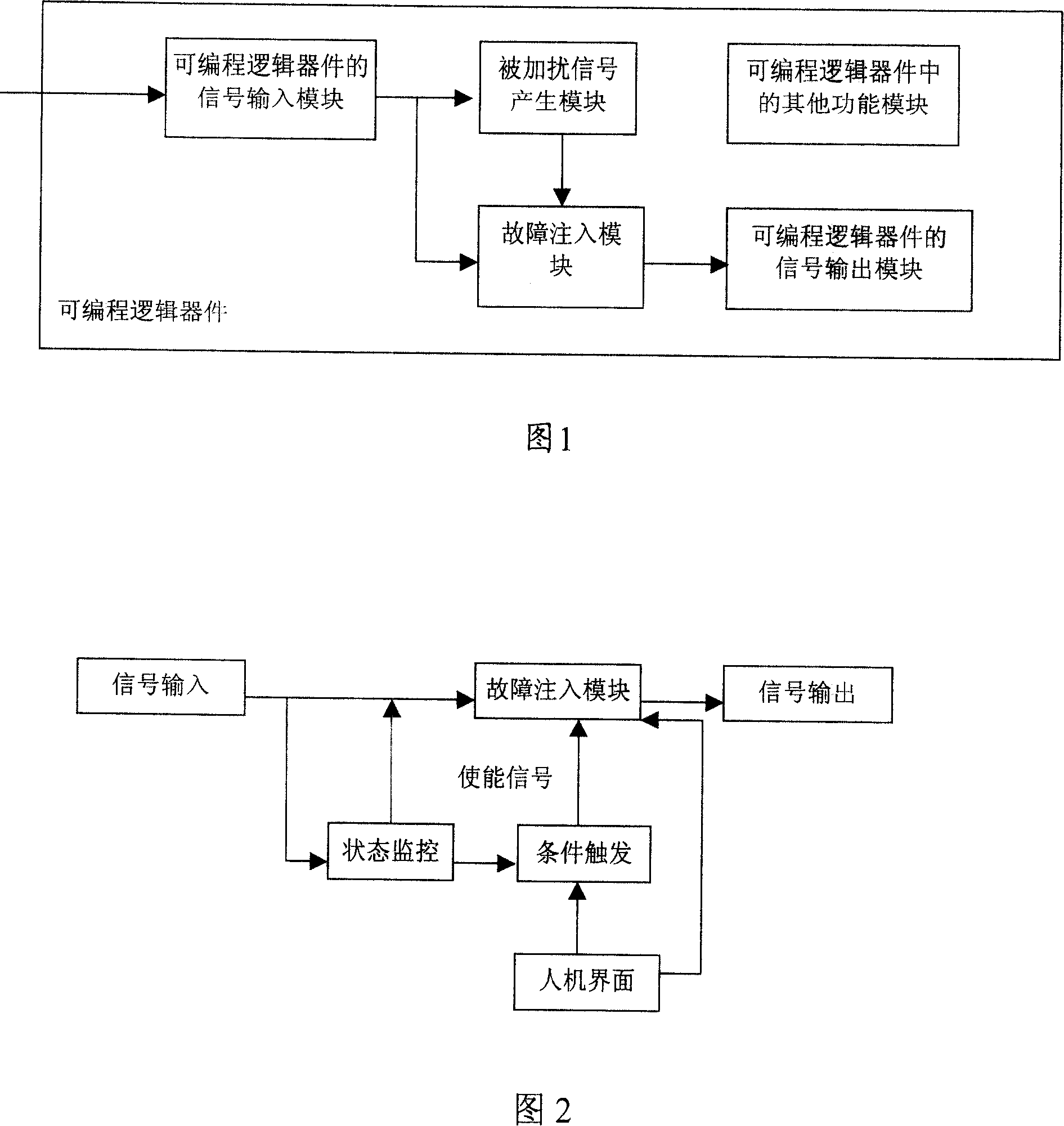

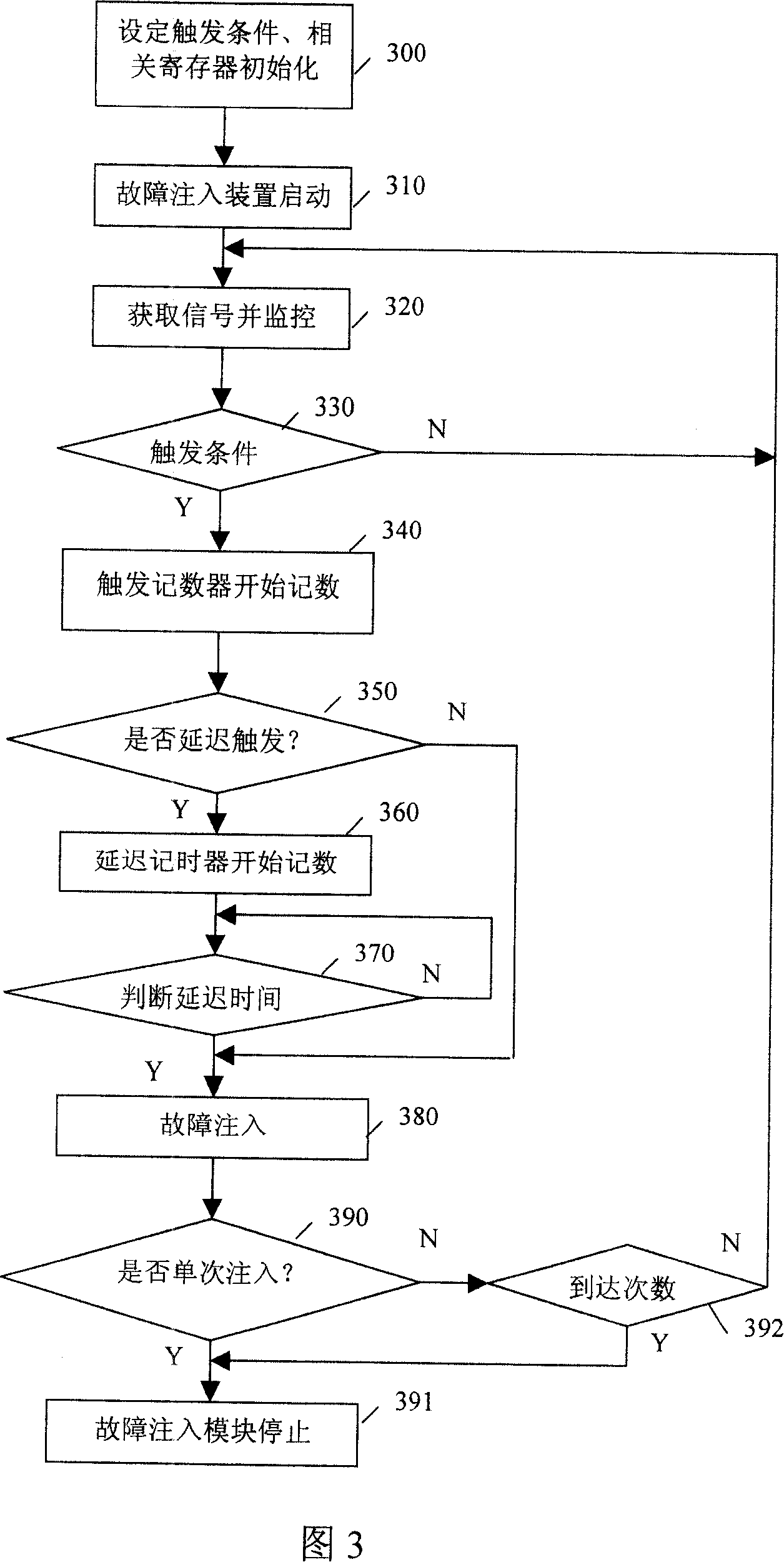

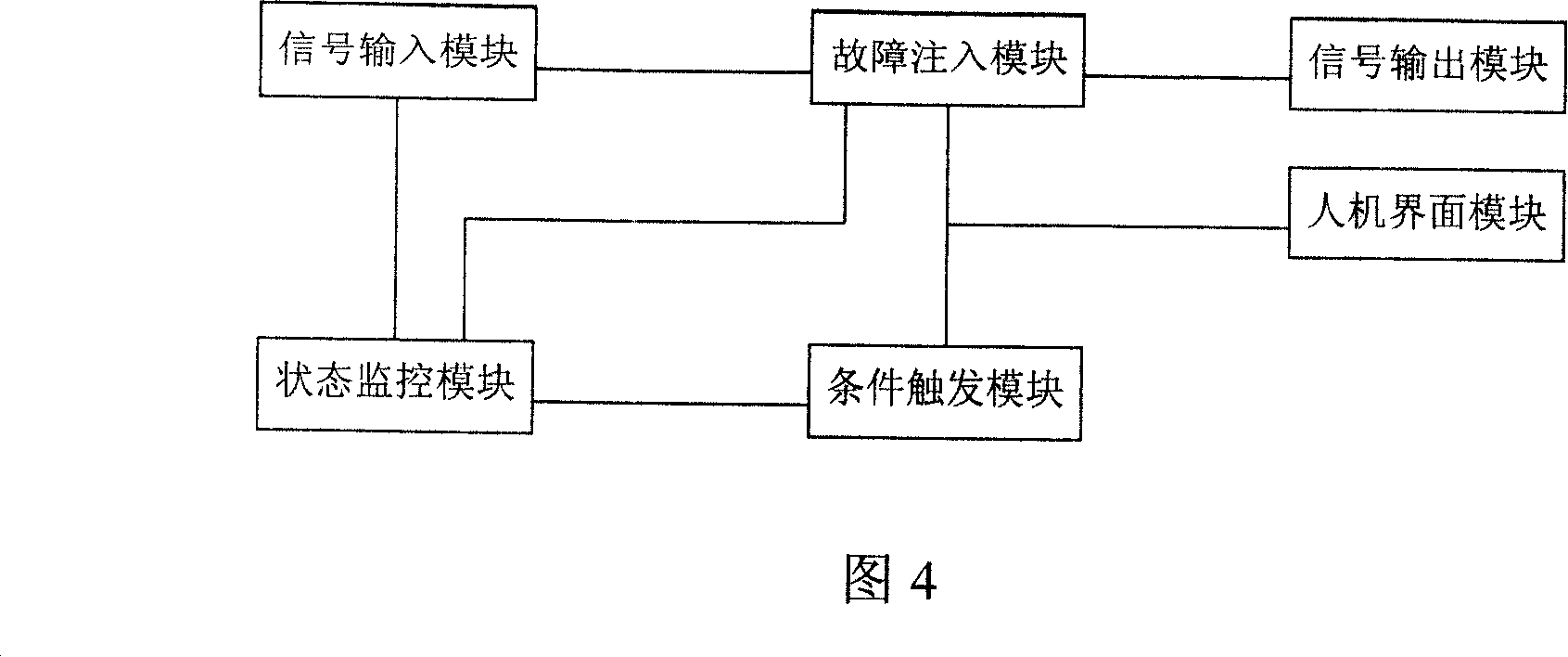

[0045] The core of the present invention is: a fault injection module is installed inside the programmable logic device that needs fault injection, and the signal of the programmable logic device is obtained, and the fault injection module injects a corresponding fault into the obtained signal, and outputs the signal after the fault injection.

[0046] The technical solution provided by the present invention will be further described below based on the core idea of the present invention.

[0047] The fault injection module built in the programmable logic device of the present invention can automatically inject corresponding faults into the signals in the programmable logic device according to the test requirements, and the signals in the programmable logic device include signals generated inside the programmable logic device and external inputs Signals in Programmable Logic Devices.

[0048] The principle of implementing fault injection by setting a fault injection module in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com