Picture-element electrode switch element and manufacturing method thereof

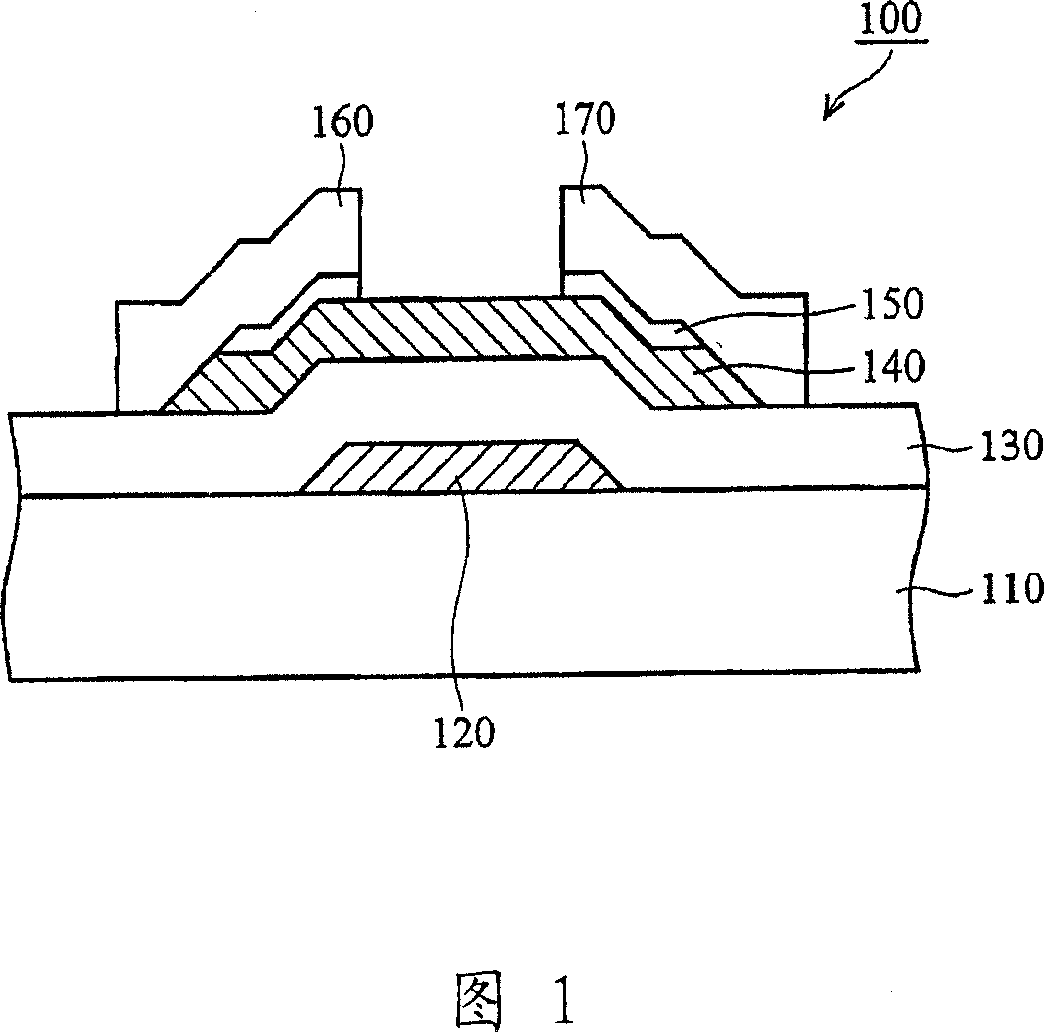

A pixel electrode and switching element technology, which is applied in the field of thin film transistor switching elements and its manufacturing, can solve problems affecting the reliability of TFT-LCD, and achieve the effect of preventing copper gate diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

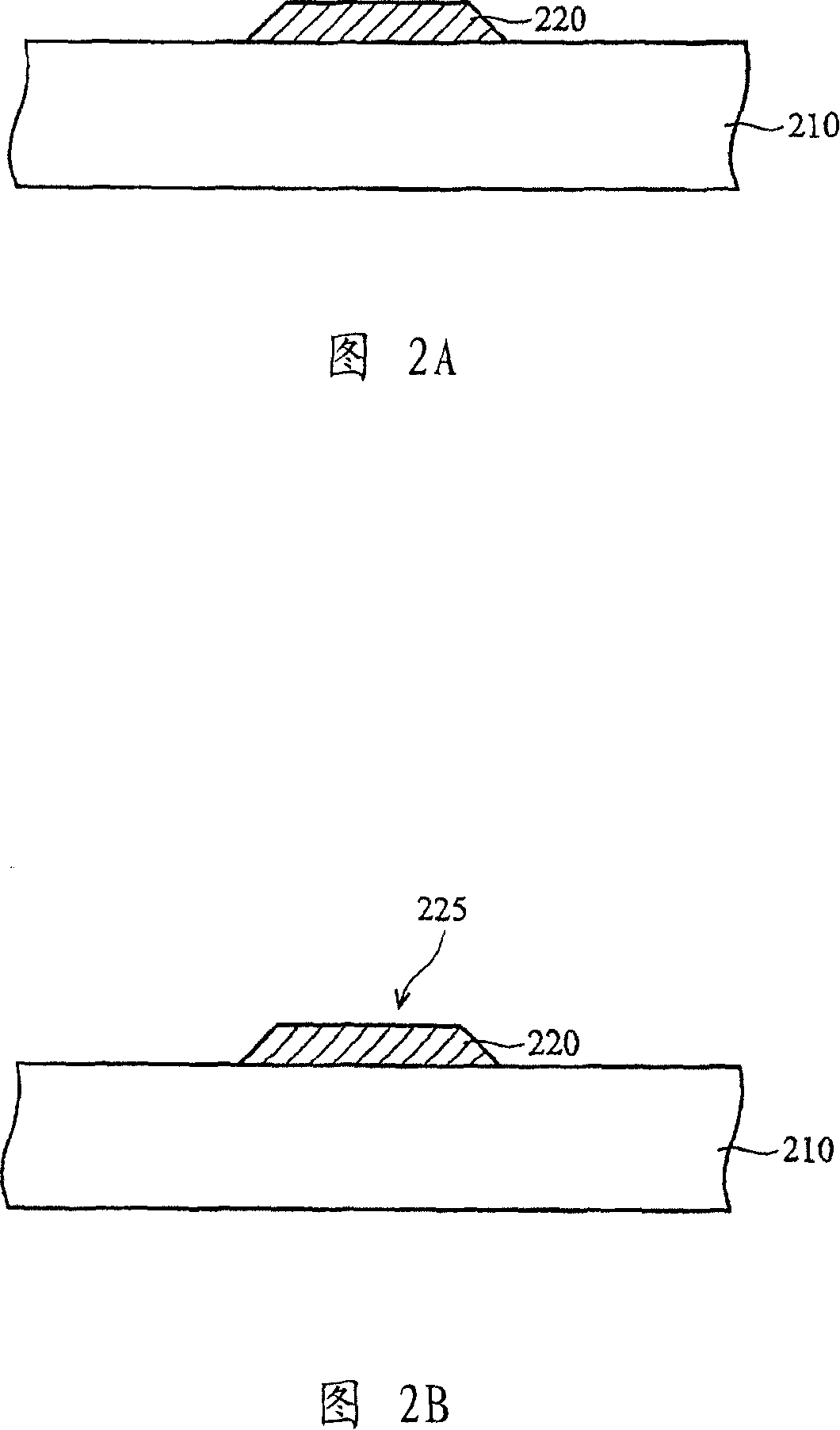

[0026] According to a preferred embodiment of the present invention, the method includes the following main steps.

[0027] As shown in FIG. 2A, a copper layer (not shown) is formed by chemical vapor deposition, electrochemical plating (ECP) or physical vapor deposition, and then a photolithographic etching process is performed to form a gate 220 on the above a substrate 210 . The substrate 210 includes a glass substrate. The gate 220 includes copper and has a thickness between about 100 and 500 nanometers.

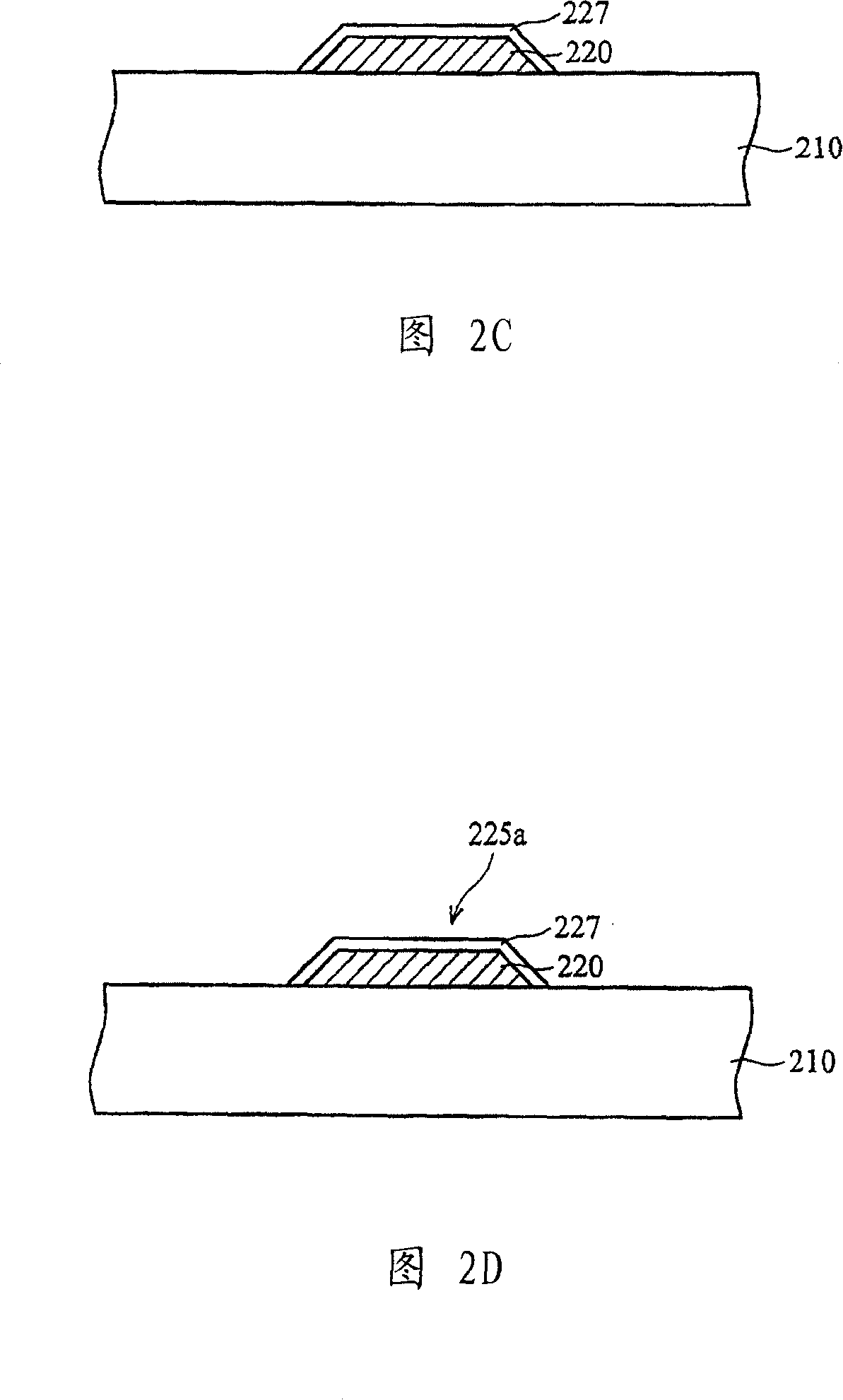

[0028] As shown in FIGS. 2B and 2C, a plasma treatment 225 is performed on the surface of the gate 220 to conformably form a first copper silicide layer 227 (CuSi x ) above the gate 220. Wherein, the plasma treatment 225 is carried out in a reaction chamber containing silane gas at a temperature of 180-370° C., and the silicon in the silane reacts with the surface of the gate 220 composed of copper to produce a first copper silicide layer 227 for use in Copper is prev...

no. 2 example

[0033] According to another preferred embodiment of the present invention, the method of the present invention includes the following steps.

[0034] As shown in FIG. 3A, a copper layer (not shown) is formed by chemical vapor deposition or electrochemical plating (ECP) or physical vapor deposition, followed by a photolithographic etching process to form a grid 220 on a above the substrate 210 . The substrate 210 includes a glass substrate. The gate 220 includes copper and has a thickness between about 100 and 500 nanometers.

[0035] As shown in FIGS. 3B and 3C, a plasma treatment 225 is performed on the surface of the gate 220 to conformably form a first copper silicide layer 227 (CuSi x ) above the gate 220. Wherein, the plasma treatment 225 is carried out in a reaction chamber containing silane gas at a temperature of 180-370° C., and the silicon in the silane reacts with the surface of the gate 220 composed of copper to produce a first copper silicide layer 227 for use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com