Acceleration sensor and manufacturing method for the same

一种加速度传感器、制造方法的技术,应用在测量加速度、速度/加速度/冲击测量、使用惯性力进行加速度测量等方向,能够解决制造工序复杂、技术上负担重等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, the present invention will be described based on the illustrated embodiments.

[0074] >>

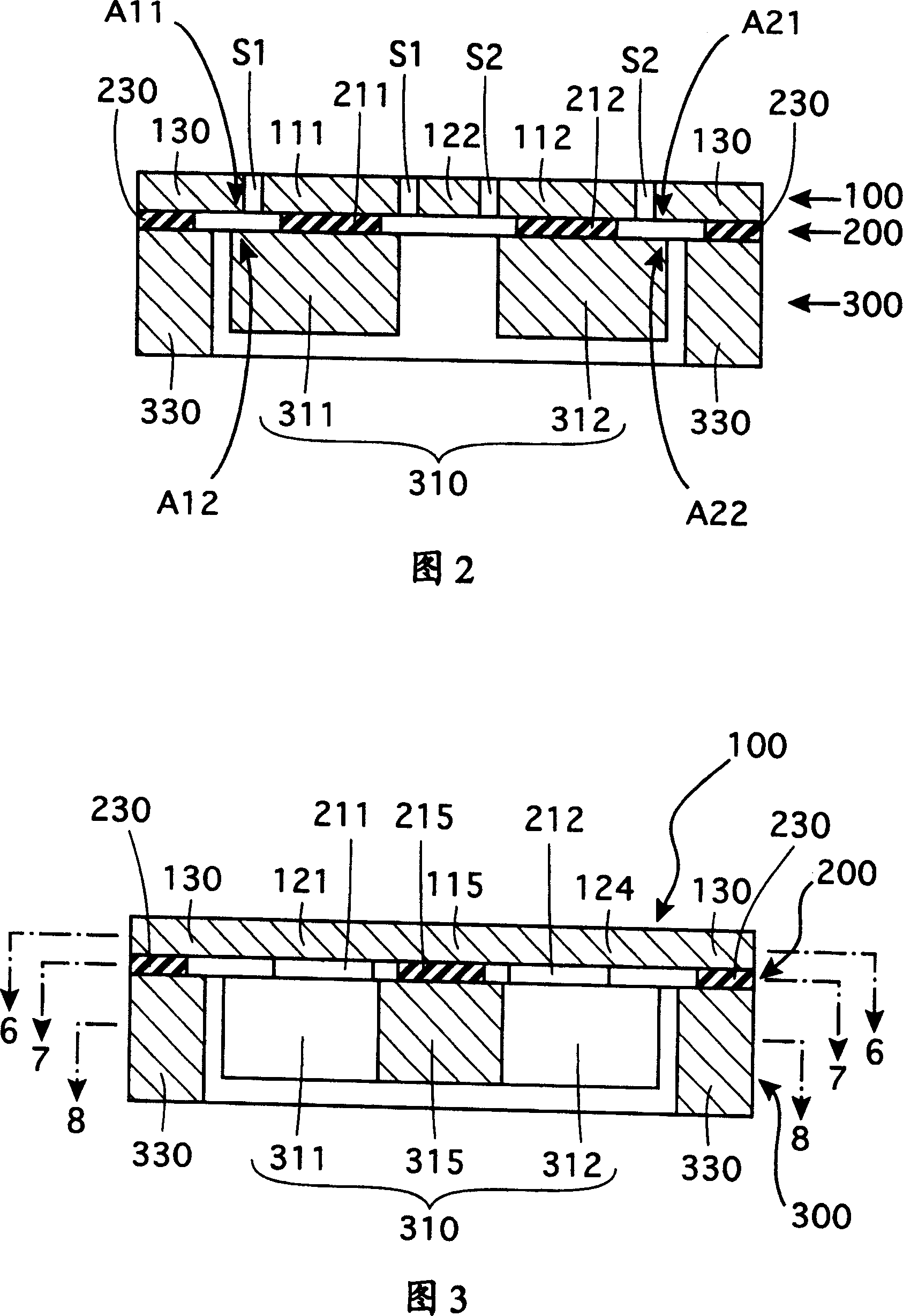

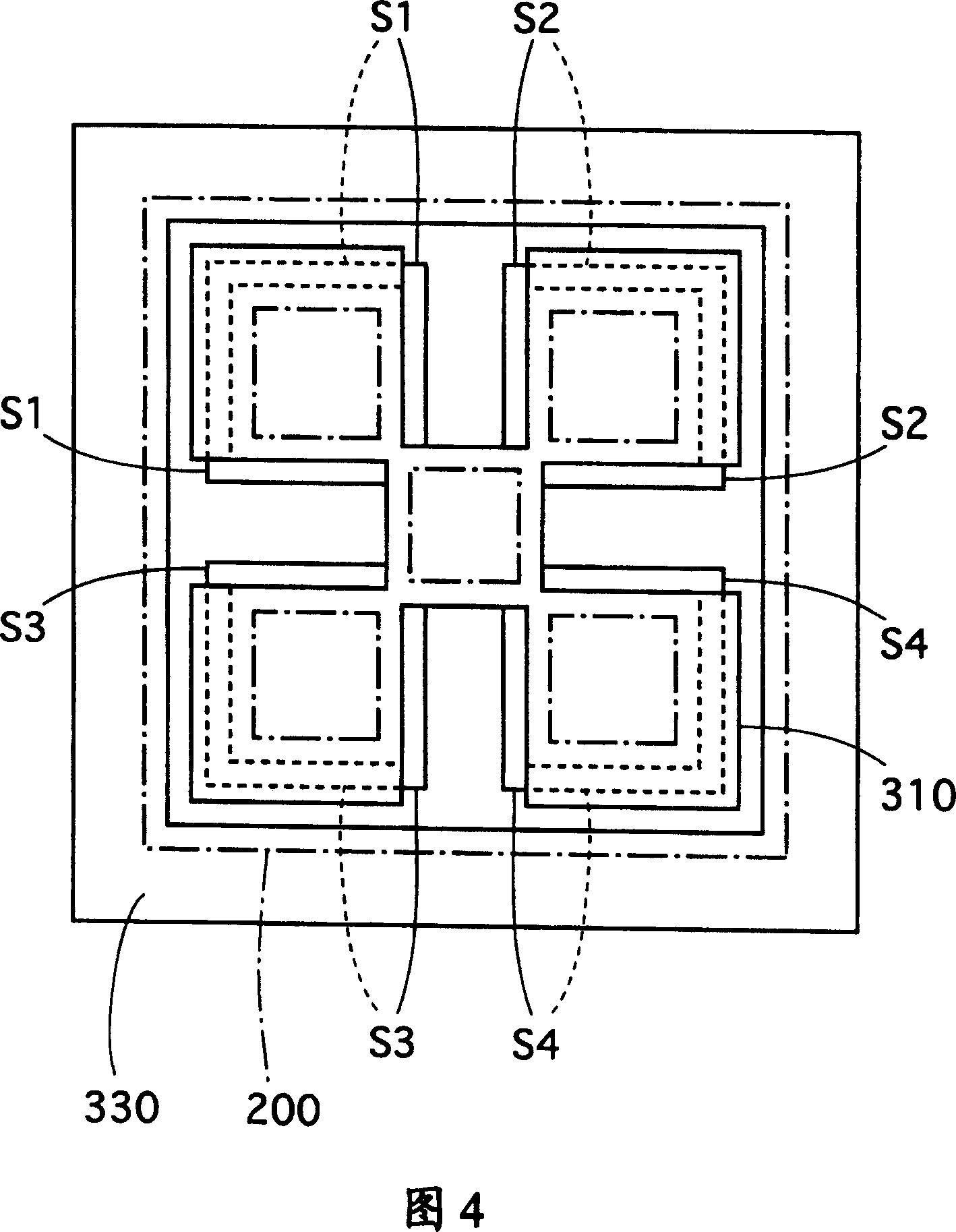

[0075] First, the basic structure of the sensor structure for detecting acceleration employed in the acceleration sensor of the present invention will be described. The constituent elements that are the backbone of this sensor structure are the substrate layer and the inertial weight. The inertia hammer is connected to the central part of the bottom surface of the substrate layer. When acceleration acts on the inertial hammer, a portion of the substrate layer is displaced due to the applied acceleration. In other words, the sensor structure is capable of converting acceleration into displacement of the substrate layer. Furthermore, as described in §3, if a displacement detecting means for electrically detecting the generated displacement is added to the sensor structure, the acceleration sensor of the present invention can be obtained.

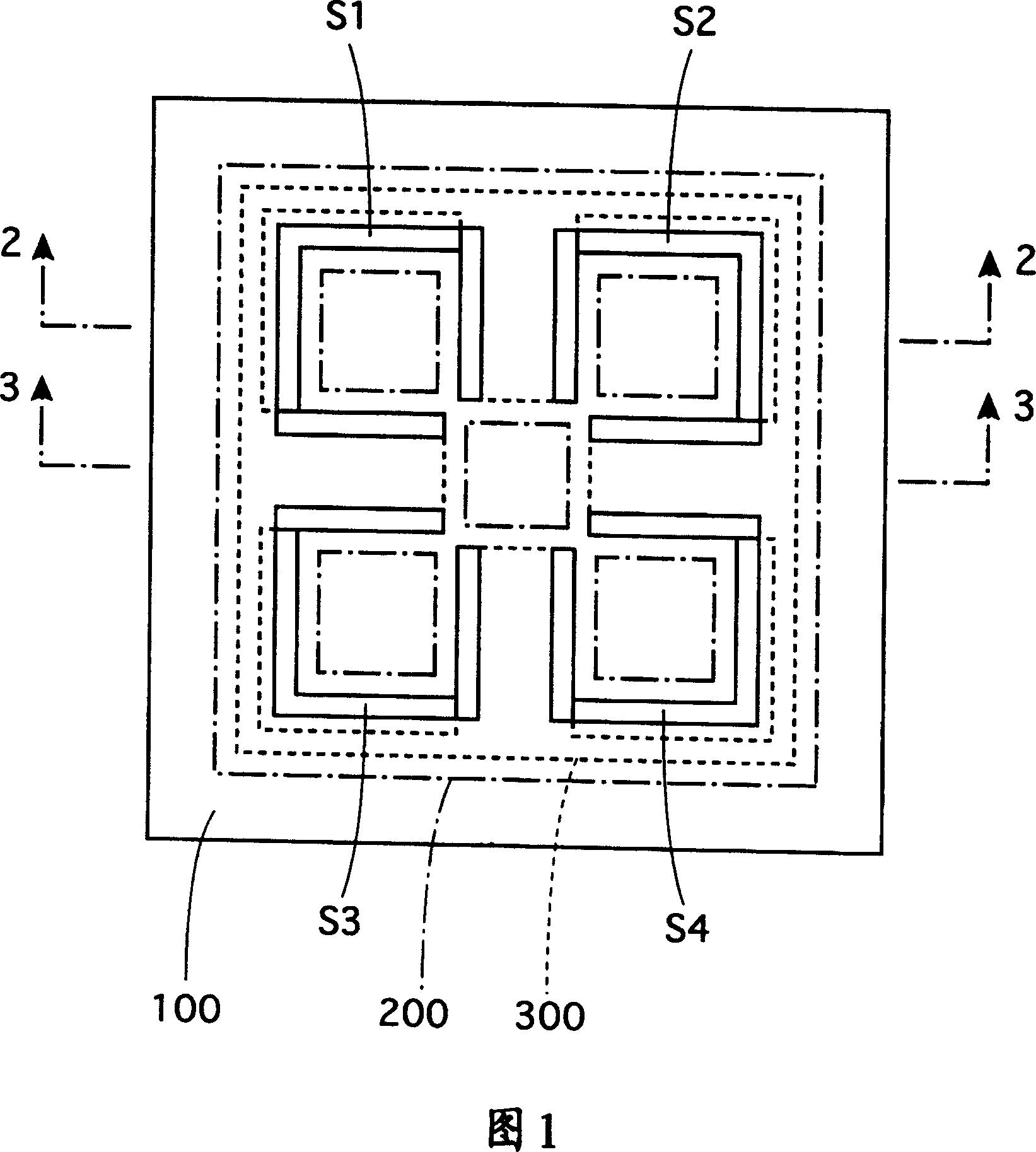

[0076] Figure 1 is a top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com