Material for thermal barrier coating

A technology of thermal insulation coating and coating film, which is applied in the direction of coating, metal material coating process, air transportation, etc., and can solve problems such as residual tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] It is known that by changing the conditions for solving the basic equations of quantum mechanics, various physical property values at the nanometer level can be obtained. This method is a non-empirical calculation method that does not use any test results as the calculation parameters and obtains the required data. It is called "first-principle calculation". In the present invention, this first-principle calculation is used to estimate the thermal expansion coefficient α and the thermal conductivity λ from the crystal structure.

[0051] (From; http: / / www.nistep.go.jp / achiev / ftx / jpn / stfc / stt009j / feature3.html#4-0 "Science and Technology Trends" December 2001, Science and Technology Trends Research Center, Science and Technology Policy Research Institute, Ministry of Education, Culture, Sports, Science and Technology of Japan)

[0052] First, the inventors studied the thermal expansion coefficient α and thermal conductivity λ estimated from the crystal structure based on t...

Embodiment 2

[0069] In this example, the composite of the materials whose thermal expansion coefficient and thermal conductivity were measured in the above-mentioned Example 1 was studied.

[0070] According to Example 1, La 2 Si 2 O 7 , La 2 Ti 2 O 7 , Sr 2 Ta 2 O 7 And LaTaO 4 Since its thermal expansion rate is lower than that of zirconia, tensile stress may be generated when it is used as a thermal insulation coating material. Therefore, in order to maintain the low thermal conductivity of these materials and increase the coefficient of thermal expansion, the combination of them with other high thermal expansion materials described in Table 1 has been studied.

[0071] When two types of ceramics with a large difference in thermal expansion coefficient are combined, the thermal expansion coefficient of the composite material (α c ) Is represented by the following equation (3) called Turner's equation. In formula (3), α is the thermal expansion rate, K is the bulk modulus of elasticity, V is...

Embodiment 3

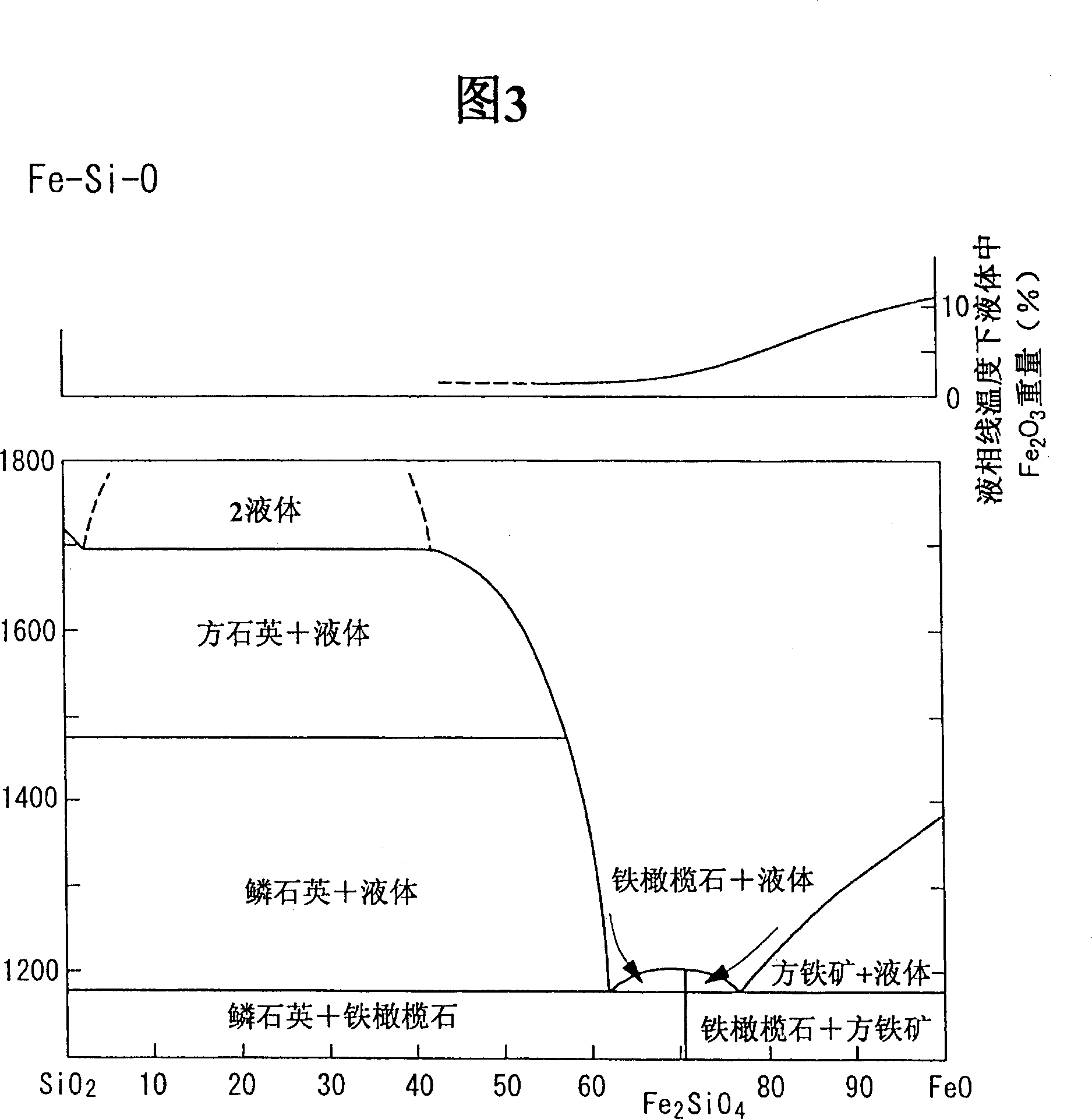

[0084] Although Mg 2 SiO 4 It is used as an insulating material in electronic and electrical equipment such as IC substrates and components, but there are no examples of high-temperature structural materials represented by thermal insulation coatings. The inventors focused on Mg 2 SiO 4 With high thermal expansion and low thermal conductivity, considering the application in thermal insulation coating, first of all, Mg 2 SiO 4 And similar compounds were studied.

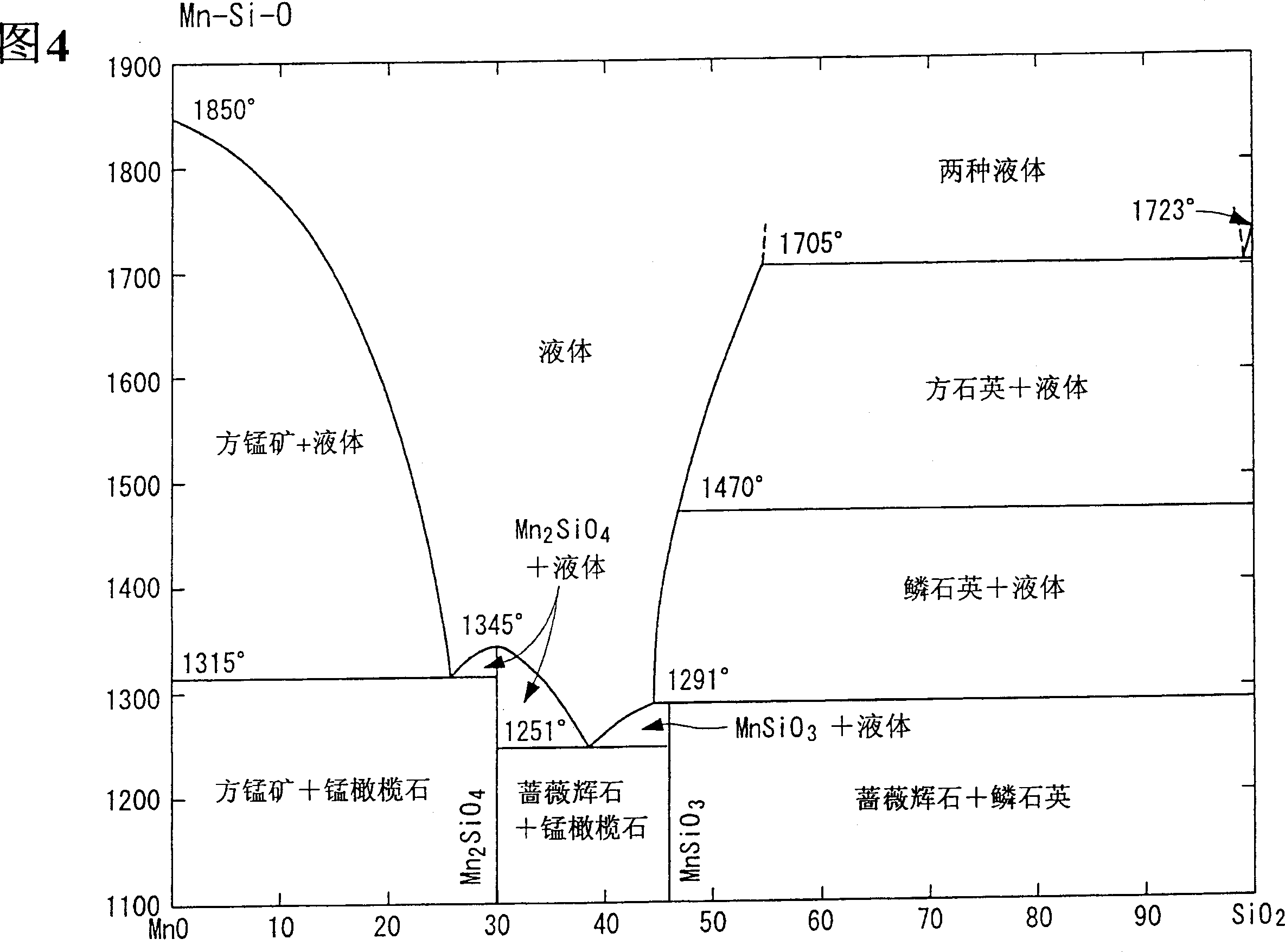

[0085] Mg 2 SiO 4 The mineral name of forsterite is forsterite, which is classified as M according to the space group Pmnb 2 SiO 4 (M is a divalent metal element) material with an olivine structure. Belongs to this kind of orthorhombic crystal, which has a classification of M according to the space group Pmnb 2 SiO 4 (M is a divalent metal element) The olivine type structure material also has Fe 2 SiO 4 (Mineral name iron olivine), Mn 2 SiO 4 (Mineral name manganese olivine), Ni 2 SiO 4 (Mineral name nickel olivine), Co 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com