Turbine bucket assembly and turbine system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

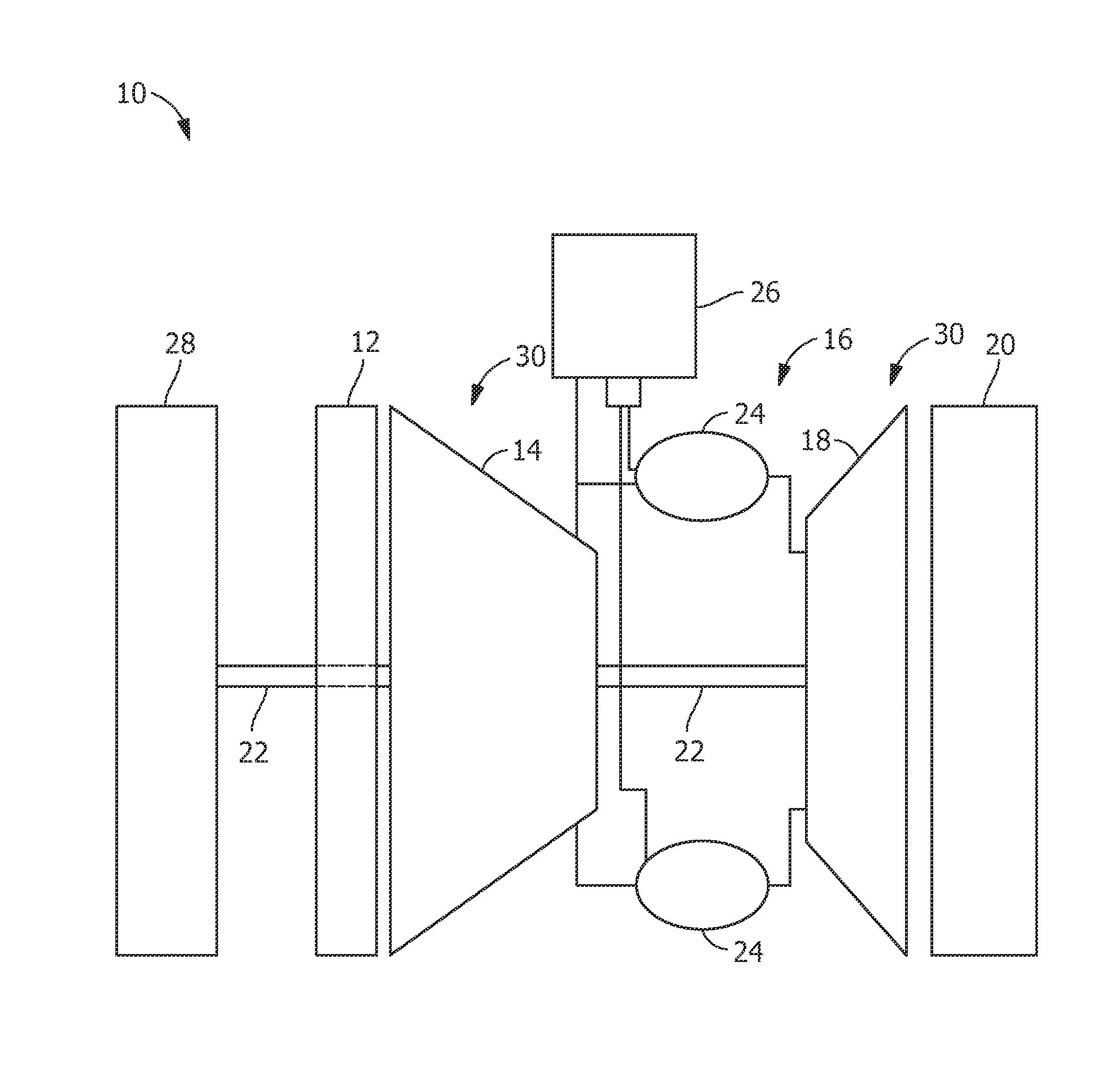

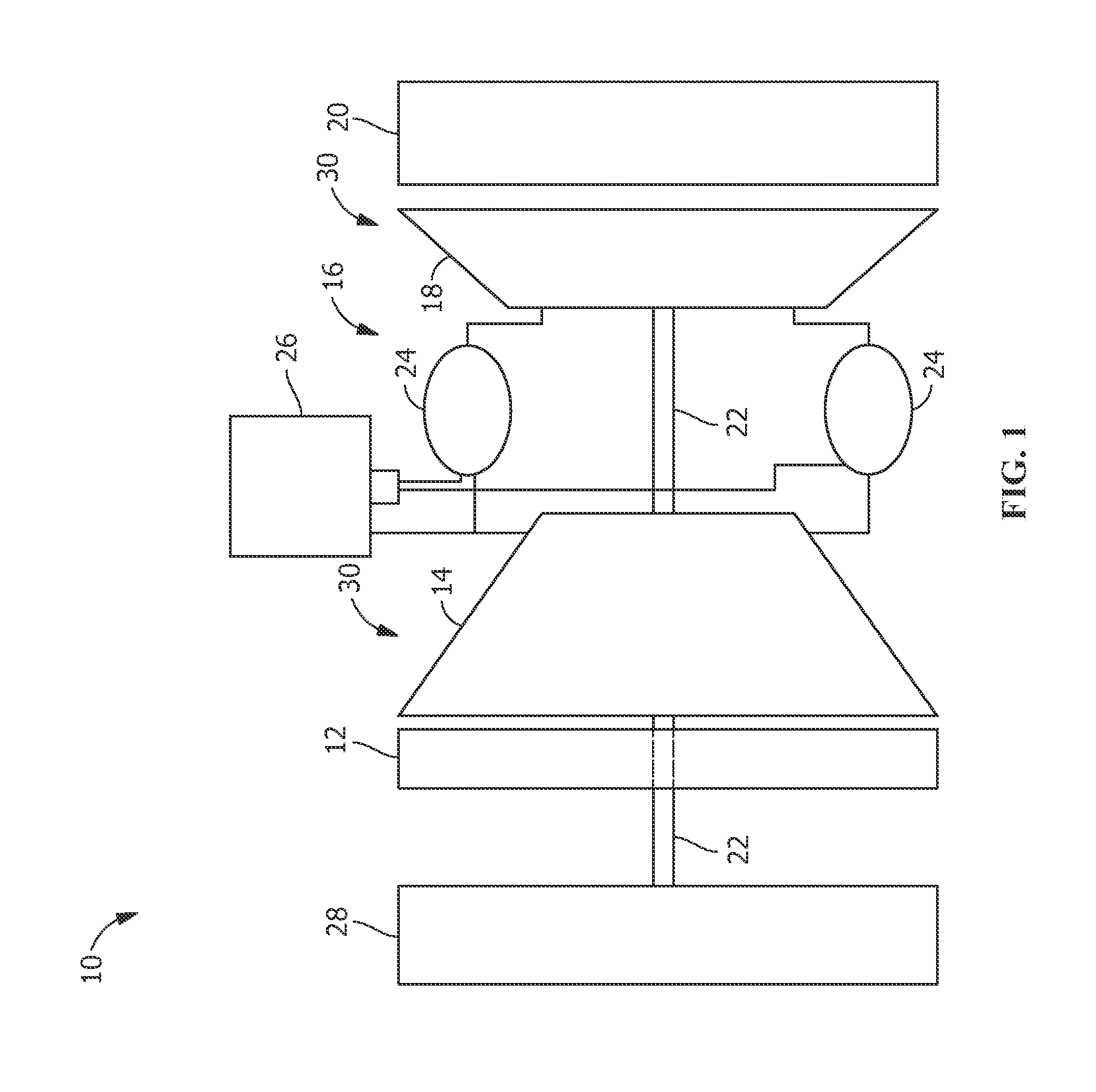

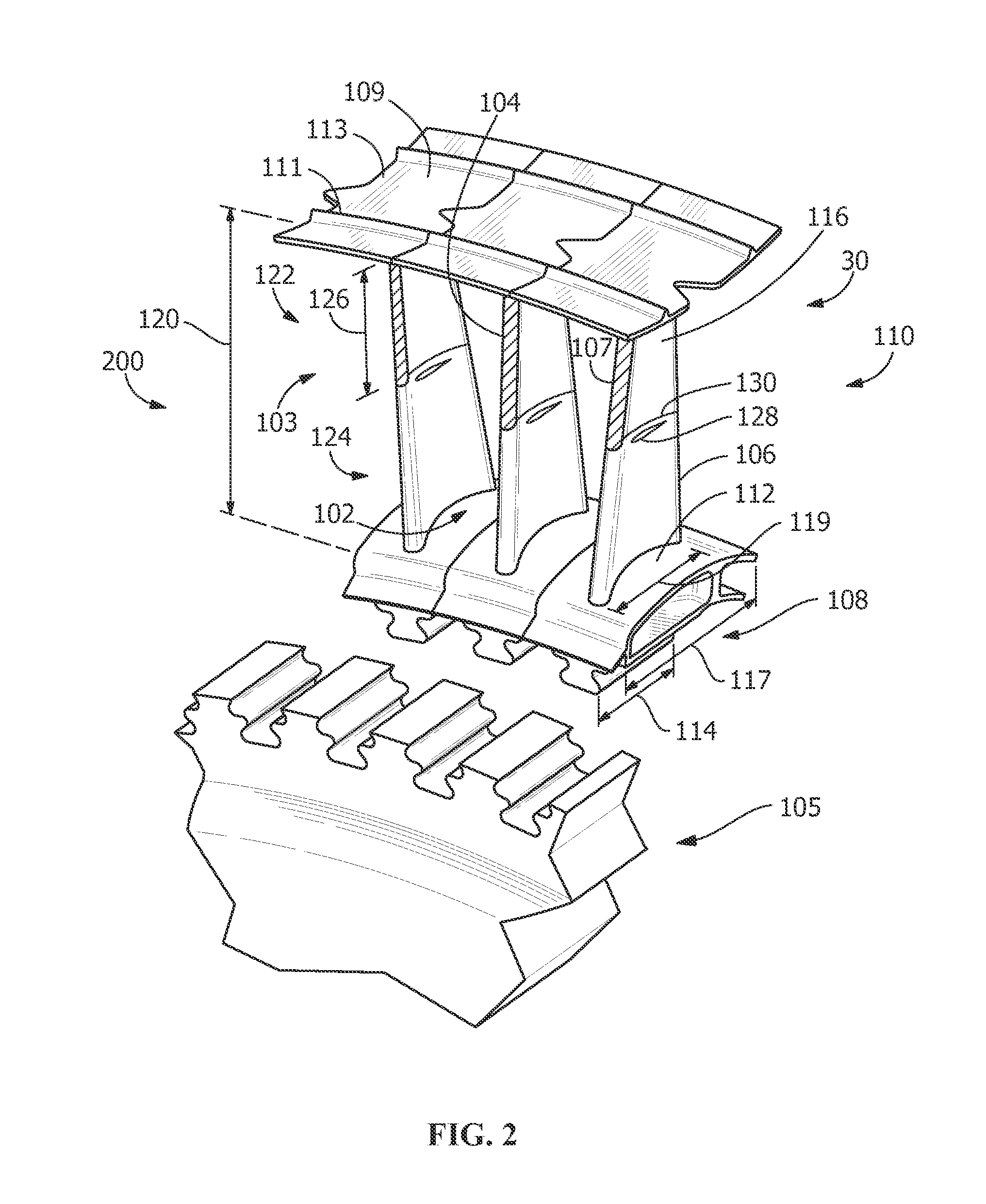

[0013]Provided is a turbine bucket assembly and a turbine system. In addition, methods of assembling and / or producing such turbine bucket assemblies and turbine systems are apparent from the disclosure. Embodiments of the present disclosure, for example, in comparison to similar concepts failing to include one or more of the features disclosed herein, use a lighter material in a tip segment of an airfoil in comparison to a root segment to reduce structural loading and / or permit control of a vibratory response (in comparison to a monolithic airfoil), use a denser material in a root segment of an airfoil to reduce risk of failure (in comparison to a monolithic airfoil), permit easier repair of damage (for example, by a tip-rub event, overheating, and / or any other damaging event) by permitting the tip segment to be repaired alone without requiring more expensive and more time-consuming removal and repair / replacement of the complete turbine bucket, reduce overall operating and maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com