Water-cooled LED heat sink

A technology of light-emitting diodes and heat-dissipating devices, applied in cooling/ventilation/heating transformation, electrical components, electric solid-state devices, etc., can solve the problems of reducing brightness, the inability of diodes to effectively dissipate heat, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides a water-cooled light-emitting diode cooling device, which is equipped with a heat-conducting liquid, a liquid flow pipeline, a heat exchanger, and a pump so that heat can be taken away by water circulation, and the advantages of water cooling can be fully utilized.

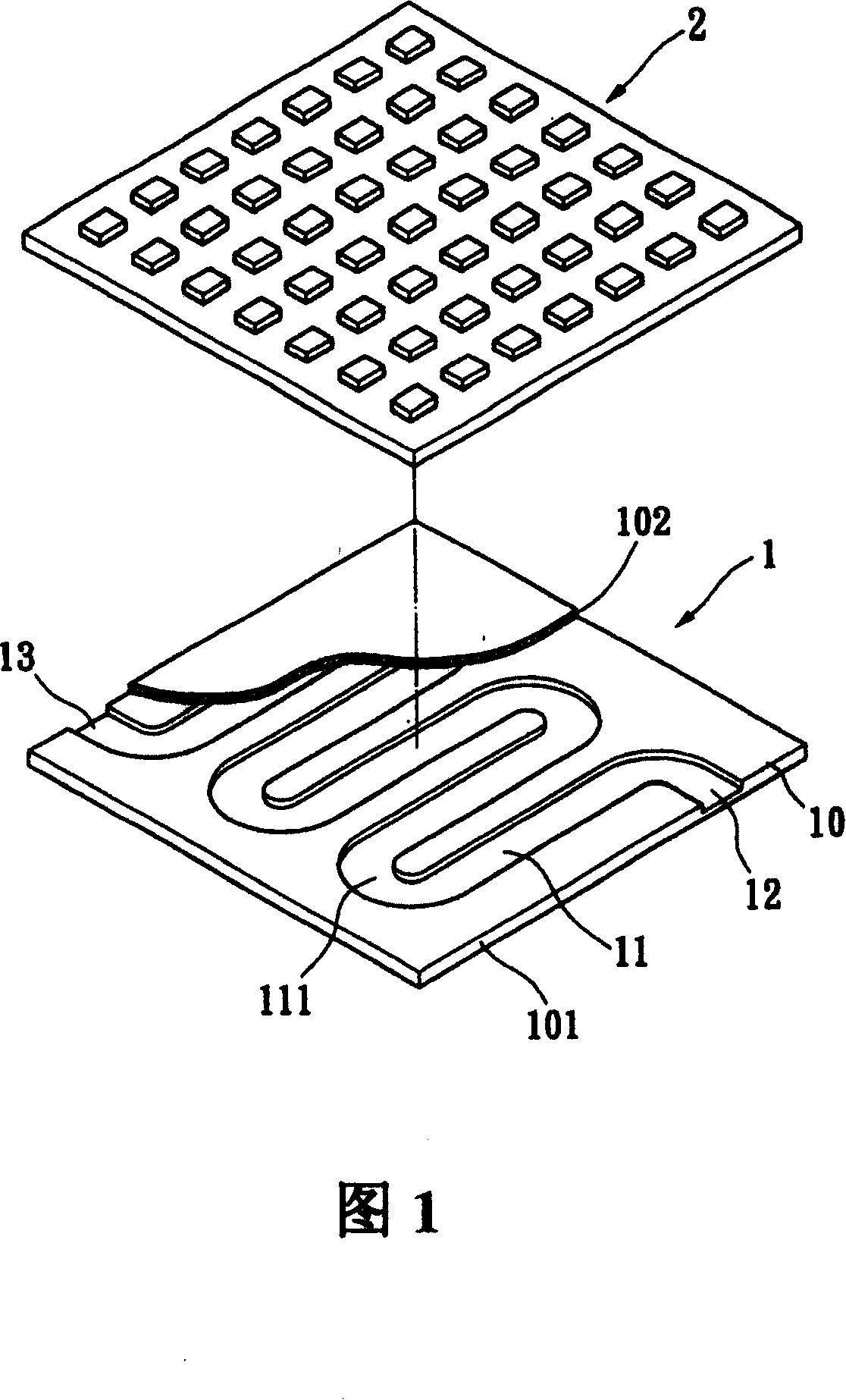

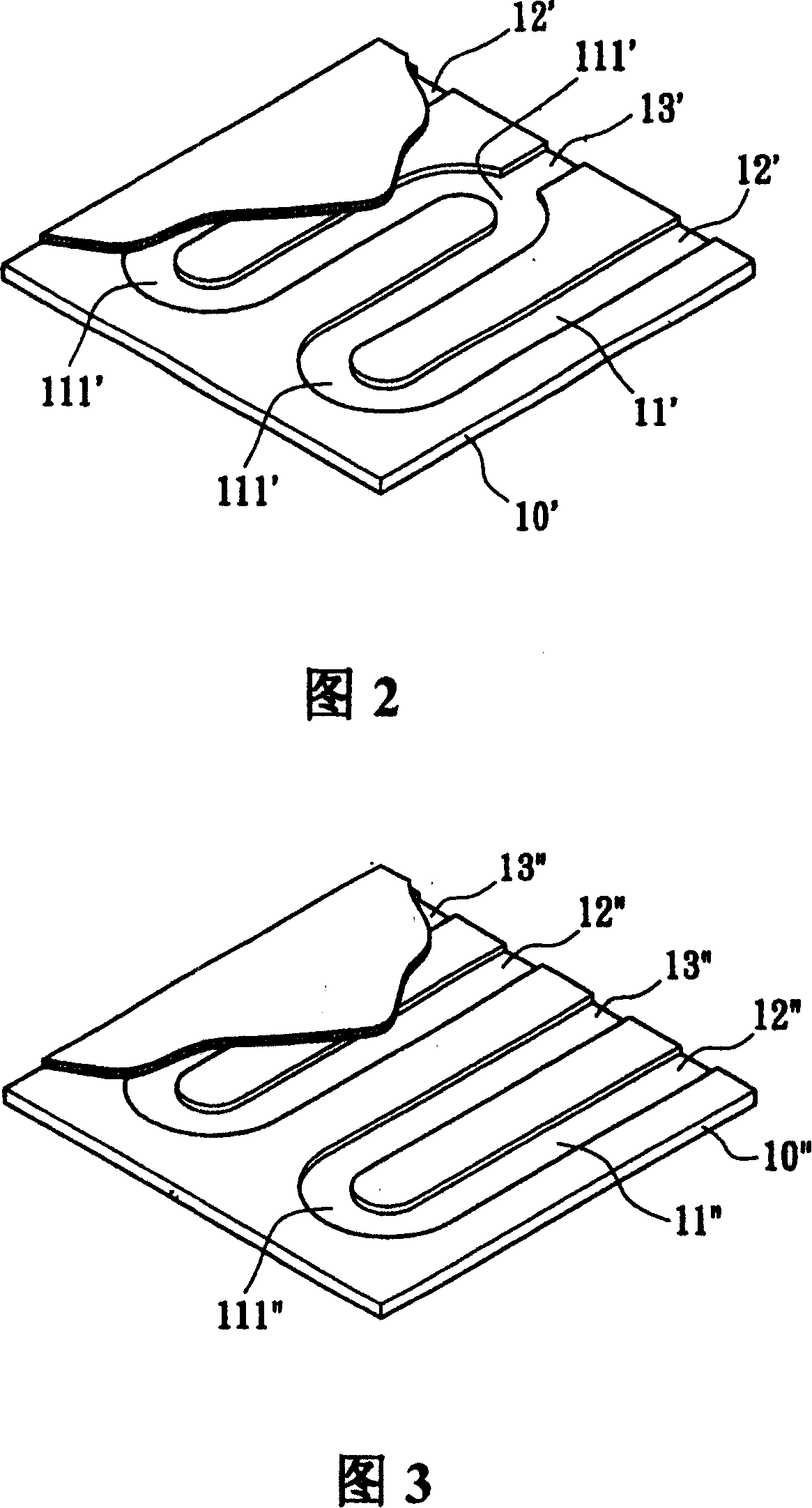

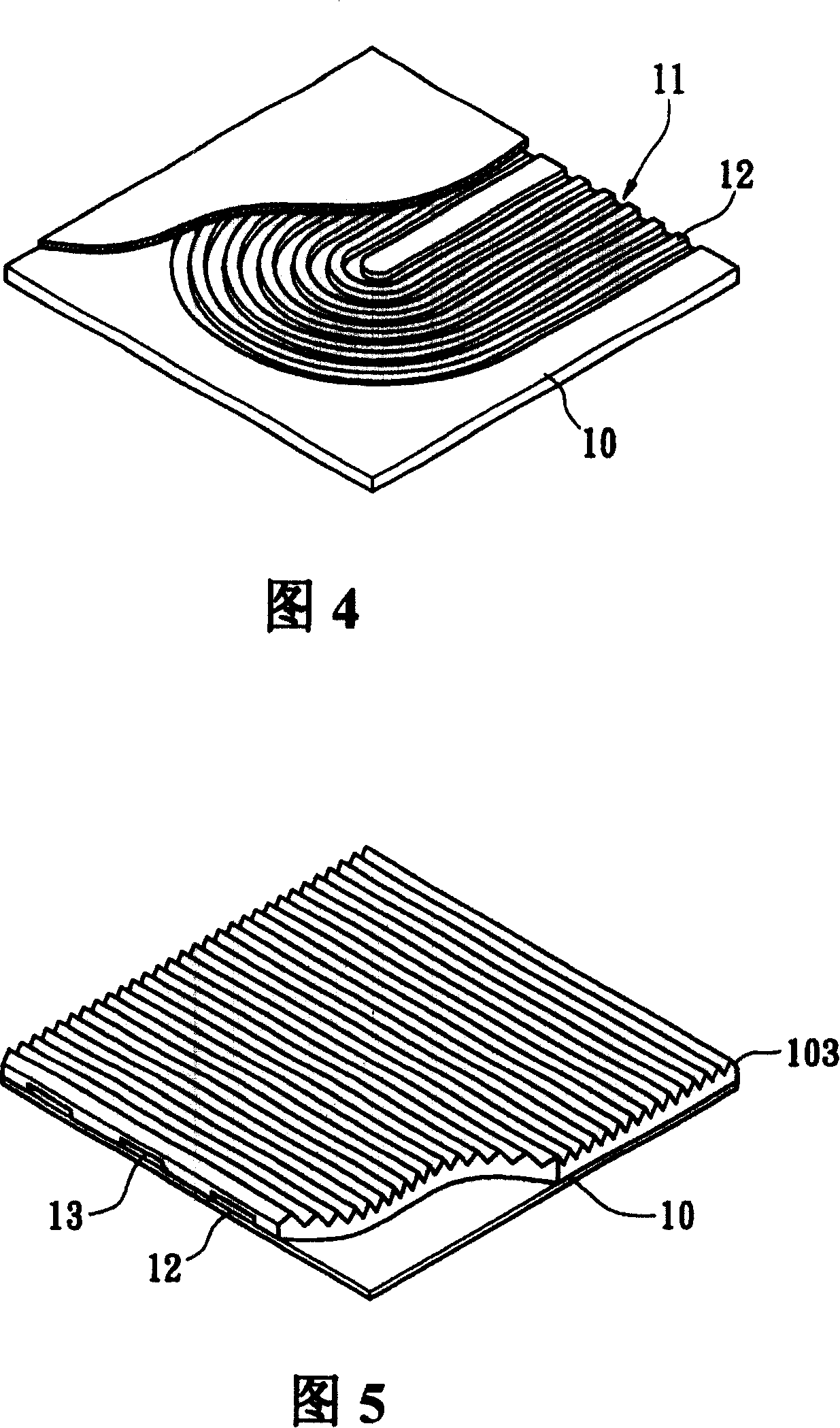

[0036] Please refer to the structural diagram shown in FIG. 1 , which is a water-cooled LED heat sink 1 provided by the present invention, which is applied to a light-emitting module 2 including cluster-type LEDs. The water-cooled LED cooling device 1 is at least equipped with a heat-conducting liquid, a liquid flow pipeline, a heat exchanger and a pump to work together. The water-cooled LED heat sink includes a heat sink body 10, at least one curved channel 11, at least one water inlet 12, and at least one water outlet 13; the curved channel 11 is recessed in the heat sink body 10 and accommodates the heat conducting The liquid flows in it, and the curved channel 11 includes at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com