Bridge surface water-proofing layer tearing equipment

A technology of waterproof layer and rolling guide rail, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems that cannot be applied on-site test and low degree of automation, and achieve the effect of complete functions, compact structure and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

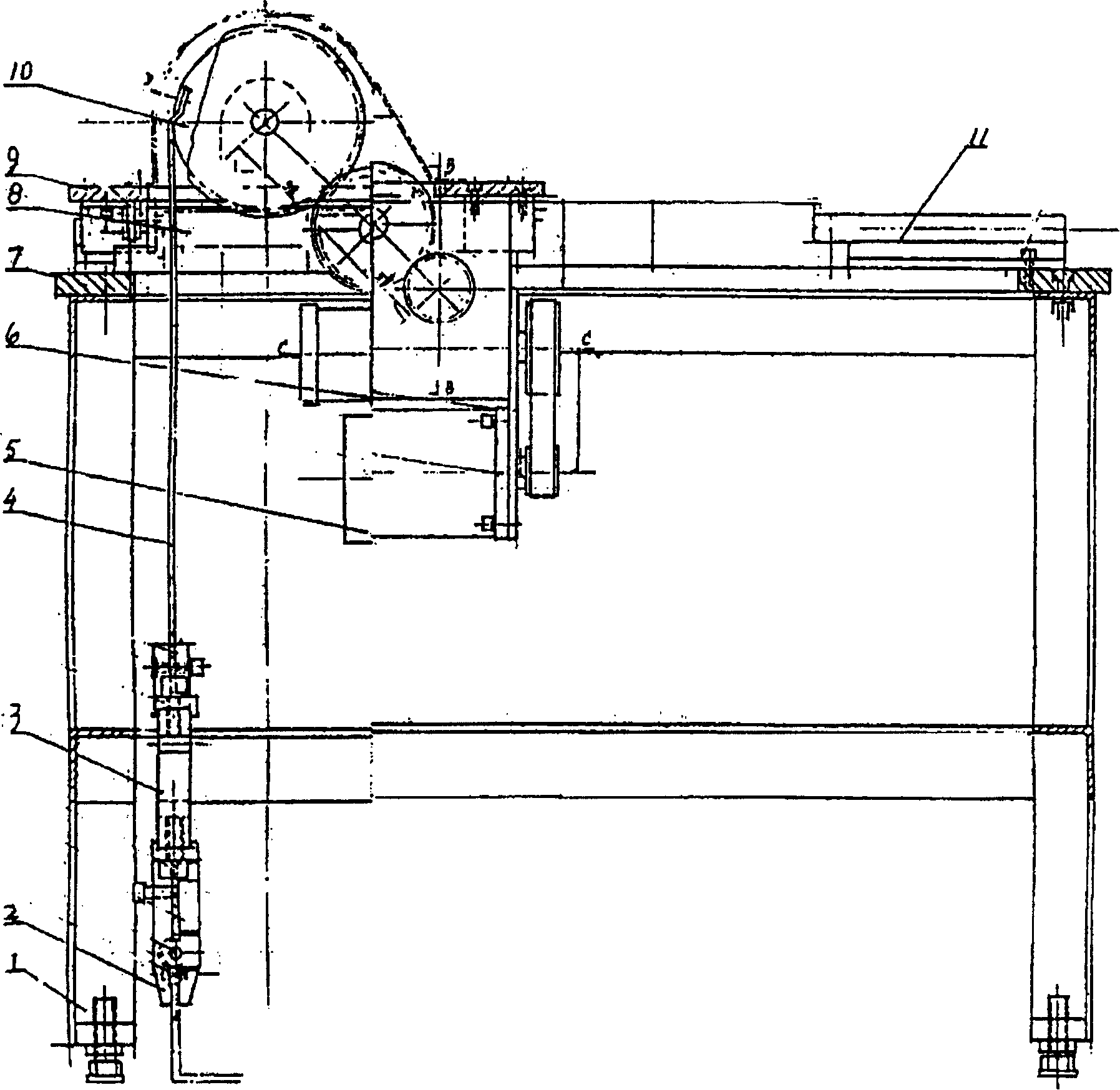

[0039] see figure 1 , Bridge Deck Waterproof Layer Tear Tester is mainly used to test the bonding strength of the concrete bridge deck and the waterproof layer after bonding in the 90° direction. It is suitable for indoor or on-site detection of waterproofing of coiled materials or reinforced coatings. In order to analyze the influence of different bridge deck treatment measures, bridge deck conditions, ambient temperature and other factors on the interlayer adhesion, the test results can be used to select waterproof materials and judge the construction quality of the waterproof layer on site. The test method is to clamp the waterproof layer on the tear clip and tear it vertically upwards. The test system continuously collects force and displacement data and stores them until the waterproof layer is separated from the concrete slab. The present invention includes support 1, because the force direction of tearing must always keep 90° with the bonding surface of the waterproof l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com