Formation method of sealed nickel metal hydride secondary battery

A nickel metal hydride, secondary battery technology, applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, climate sustainability, etc., can solve the problems of occupying production equipment and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

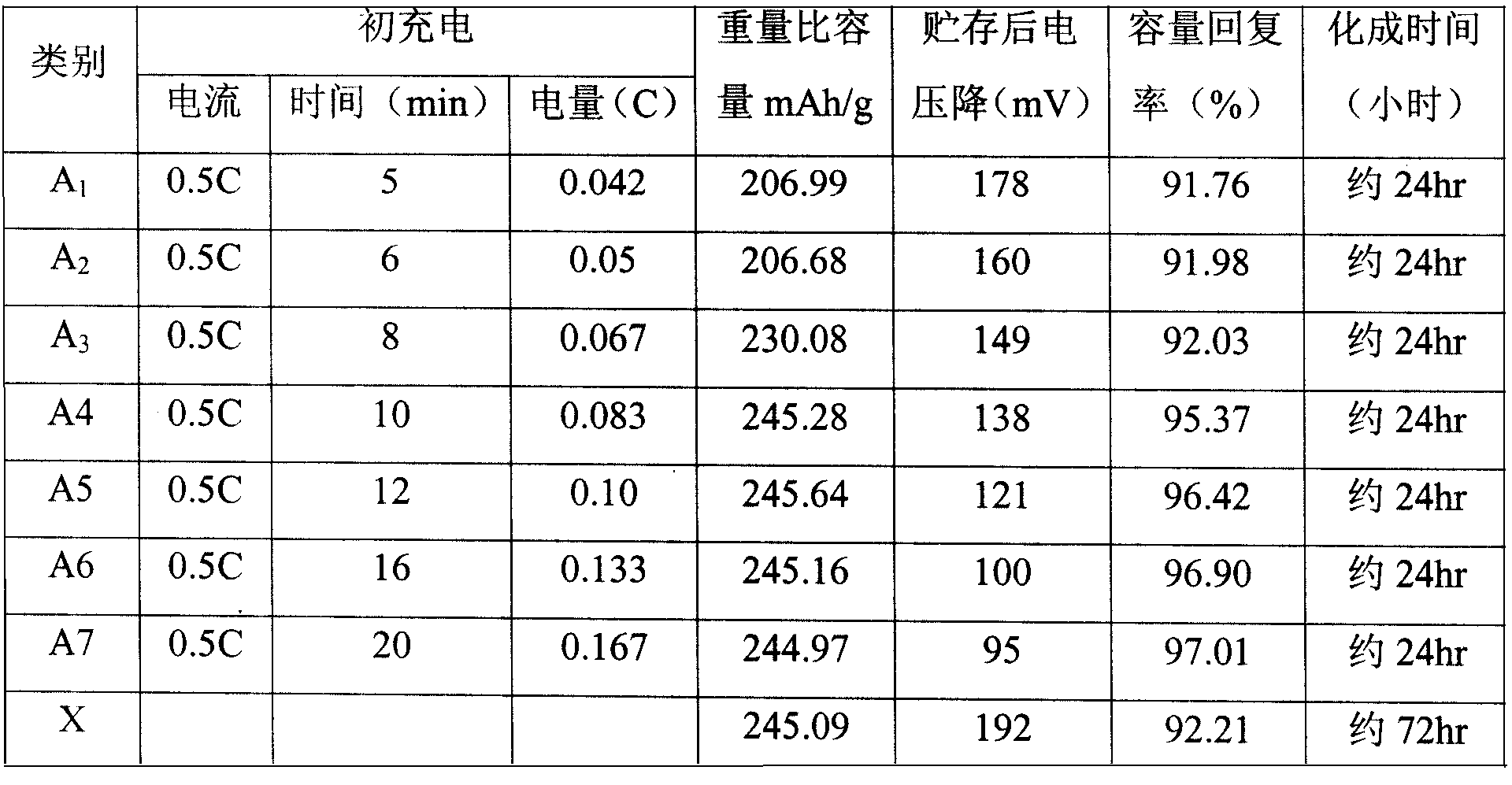

Embodiment 1

[0020]95 parts by weight of commercially available spherical nickel hydroxide (1.5wt% Co and 3wt% Zn in solid solution) with an average particle diameter of 15 μm, add 5 parts by weight of cobalt monoxide with an average particle diameter of several microns, and add deionized water, 2wt% CMC The solution and 60wt% PTFE dispersion liquid are appropriate, stirred to make a paste and filled into a foamed nickel porous body with a porosity of 95%, after drying, trimmed and shaped to make an AA-type 1800mAh nickel positive electrode sheet.

[0021] Using MmNi 5 The negative electrode sheet made of similar hydrogen storage alloy powder and the polypropylene diaphragm are combined with the above positive electrode to form an electrode group and inserted into the AA-shaped steel shell, and the alkaline electrolyte with a specific gravity of about 1.30, mainly potassium hydroxide, is injected and sealed. AA-shaped cylindrical sealed nickel metal hydride secondary battery with a capacit...

Embodiment 2

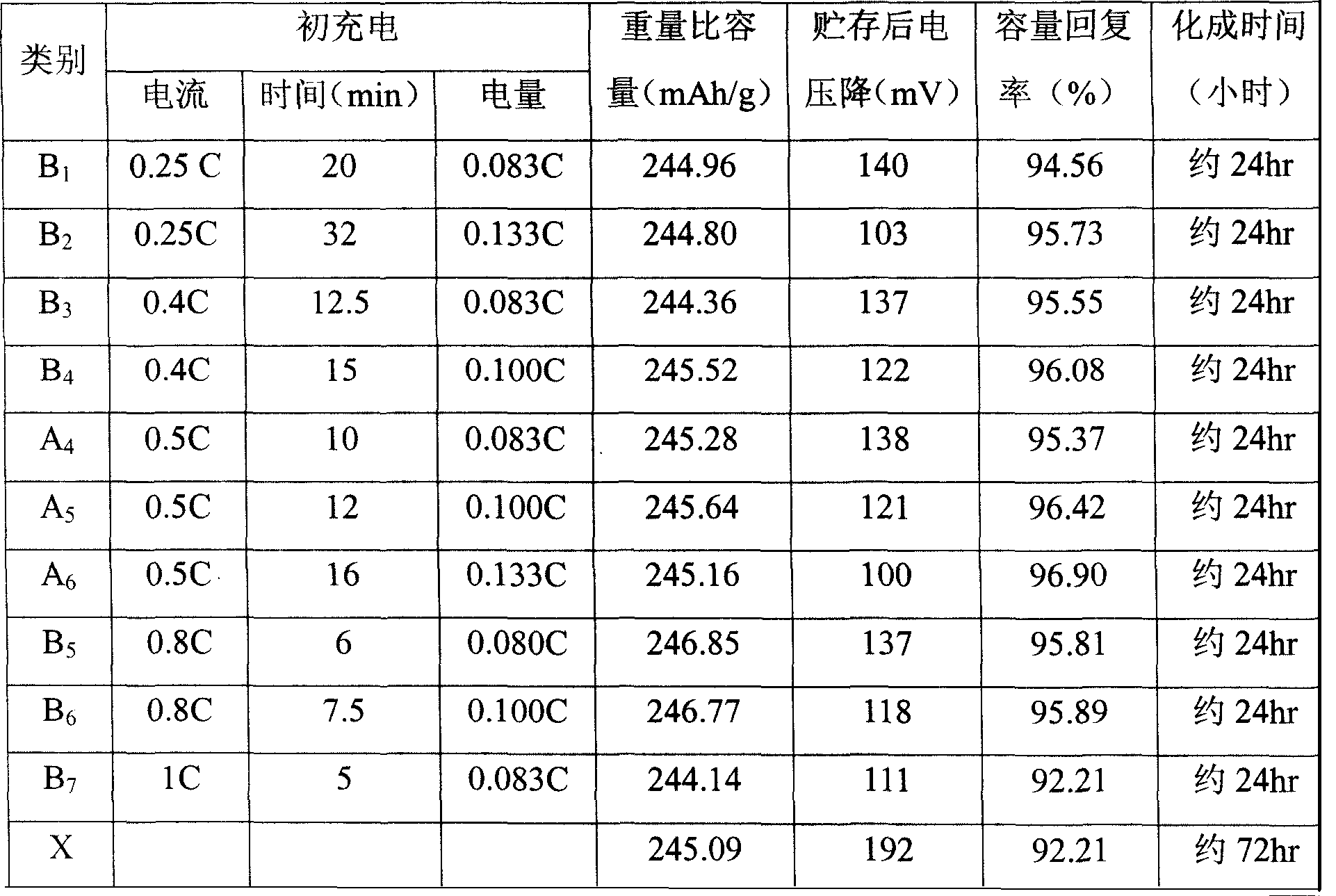

[0030] Using the same raw materials and manufacturing process as in Example 1, an AA-shaped cylindrical sealed nickel-metal hydride secondary battery with a capacity specification of 1800 mAh was manufactured. It takes about 1 hour from injecting alkaline electrolyte to sealing. Charge each battery immediately after sealing, charging at 0.25C for 20 minutes, 0.25C for 32 minutes, 0.4C for 12.5 minutes, 0.4C for 15 minutes, 0.8C for 6 minutes, 0.8C for 7.5 minutes, and 1C for 5 minutes . After the initial charge, each battery was placed in an atmosphere of 45°C for 4 hours, then charged at 0.2C for 6 hours, matured in an atmosphere of 45°C for 8 hours, and then discharged at 0.2C, and cut off when the voltage was 1.0v. The various batteries mentioned above are named B 1 , B 2 , B 3 , B 4 , B 5 , B 6 , B 7 , as in Example 1, the discharge capacity was also measured to obtain the weight specific capacity, and the voltage was measured after 28 days of discharge state stora...

Embodiment 3

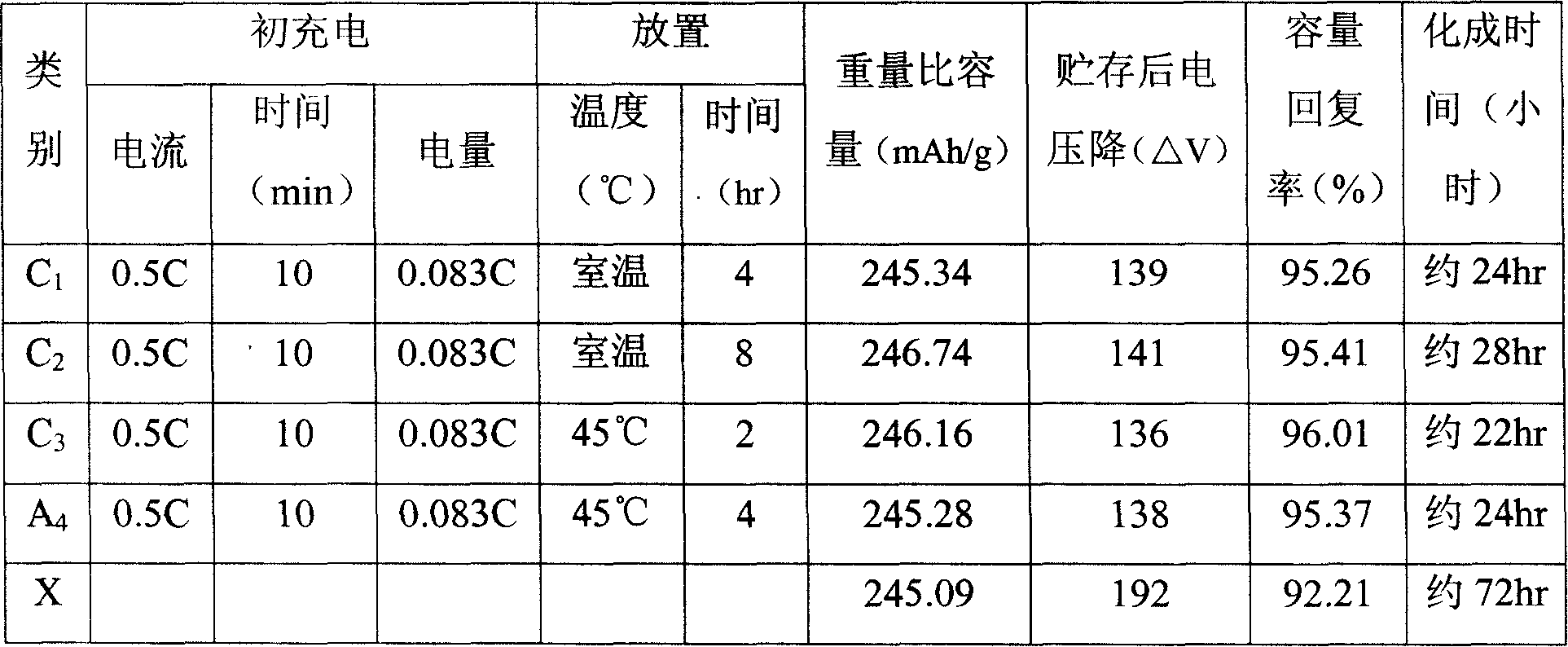

[0035] The same raw materials and manufacturing process as in Example 1 were used to manufacture a AA-shaped cylindrical sealed nickel-metal hydride secondary battery with a capacity specification of 1800mAh, wherein it was about 1 hour from the injection of the alkaline electrolyte to the sealing. After each battery was sealed, Immediately charge at 0.5C for 10 minutes. After initial charging, each battery was placed in room temperature atmosphere for 4 hours, 8 hours and 45°C atmosphere for 2 hours, then charged at 0.2C for 6 hours, matured in 45°C atmosphere for 8 hours, and then discharged at 0.2C with a voltage of 1.0 expires at v. Each of the above batteries is C 1 、C 2 、C 3 . As in the examples, the discharge capacity was also measured to obtain the weight specific capacity, and after 28 days of storage in the discharged state, the voltage was measured to obtain the voltage drop and capacity recovery rate. The corresponding data are shown in Table 3.

[0036] tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com