Pressure variable edge force difference temperature drawing method for magnesium alloy plate

A technology of variable blank holder force and magnesium alloy, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as unfavorable material flow, and achieve good heating and thermal insulation effects, easy to implement, and accurate blank holder force control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

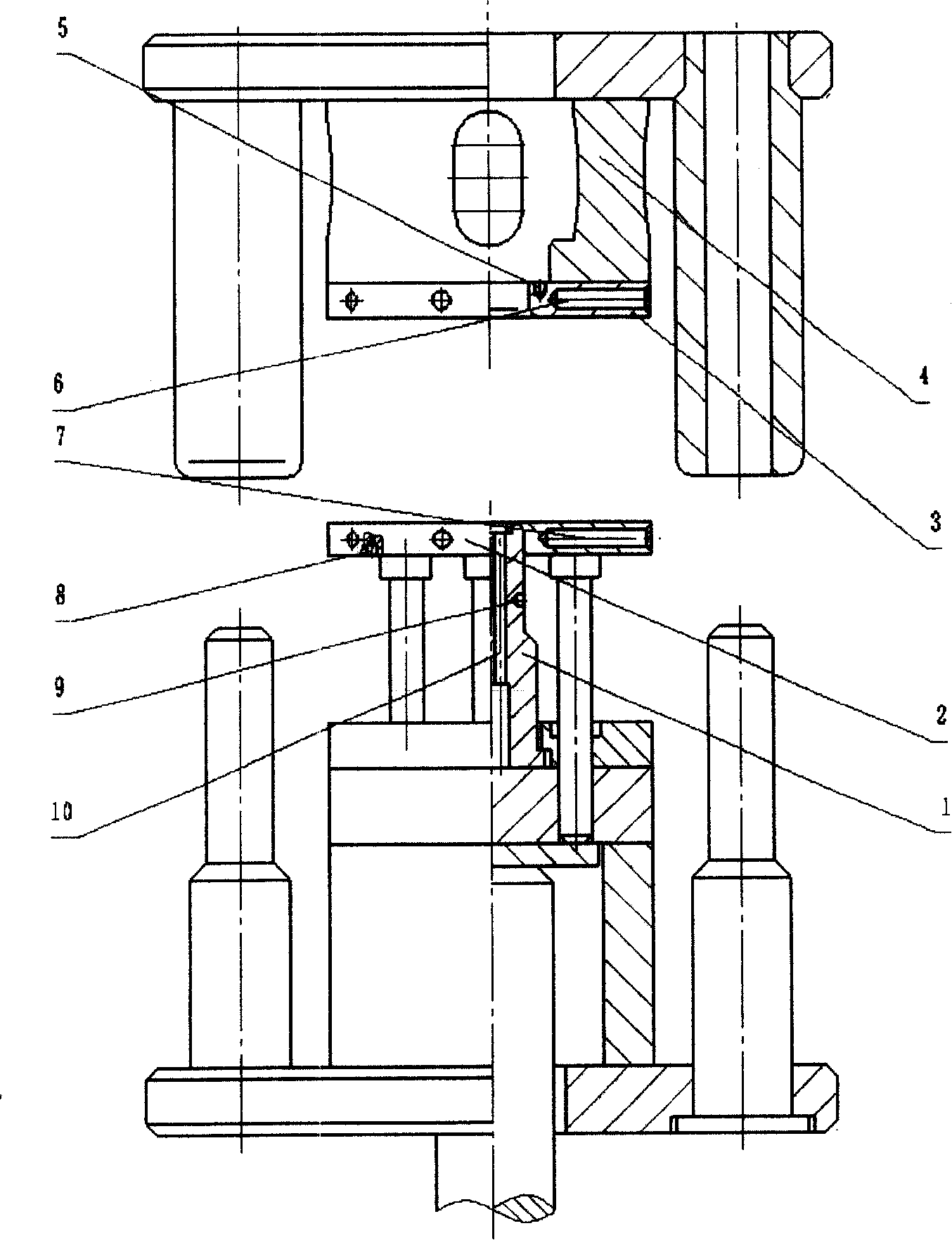

Image

Examples

Embodiment 1

[0024] Coat the 0.8mm thick AZ31 magnesium alloy slab with high-temperature-resistant lubricating oil and place it in the mold, close the mold, heat the blank holder and the die to 250°C, and pass the high-pressure air of 3Mpa from the high-pressure air compressor into the punch , keep the temperature of the punch at 30°C, hold the holding time for 10 minutes; set the initial blank-holding force to 300kN; ;The drawing speed is 20mm / min, and the limit drawing ratio can reach 3.5.

Embodiment 2

[0026] Coat the 0.8mm thick AZ31 magnesium alloy slab with high-temperature-resistant lubricating oil and place it in the mold, close the mold, heat the blank holder and the die to 225°C, and the high-pressure air of 3Mpa generated by the high-pressure air compressor is passed into the punch , keep the temperature of the punch at 40°C, hold the holding time for 10 minutes; set the initial blank-holding force to 300kN; ;The drawing speed is 20mm / min, and the limit drawing ratio can reach 3.2.

Embodiment 3

[0028] Coat the 0.8mm thick AZ31 magnesium alloy slab with high-temperature-resistant lubricating oil and place it in the mold, close the mold, heat the blank holder and the die to 200°C, and pass the high-pressure air of 3Mpa from the high-pressure air compressor into the punch , keep the temperature of the punch at 50°C, and hold the holding time for 10 minutes; set the initial blank-holding force to 300kN, set the blank-holding force to 600kN between the stroke of 20mm and 40mm, and set the blank-holding force to 400kN between the stroke of 40mm and 60mm ;The drawing speed is 20mm / min, and the limit drawing ratio can reach 3.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com