Automatic centering central frame

An automatic centering and steady rest technology, applied in positioning devices, large fixed members, manufacturing tools, etc., can solve complex and high processing and manufacturing problems, and achieve the effect of simple operation, convenient operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

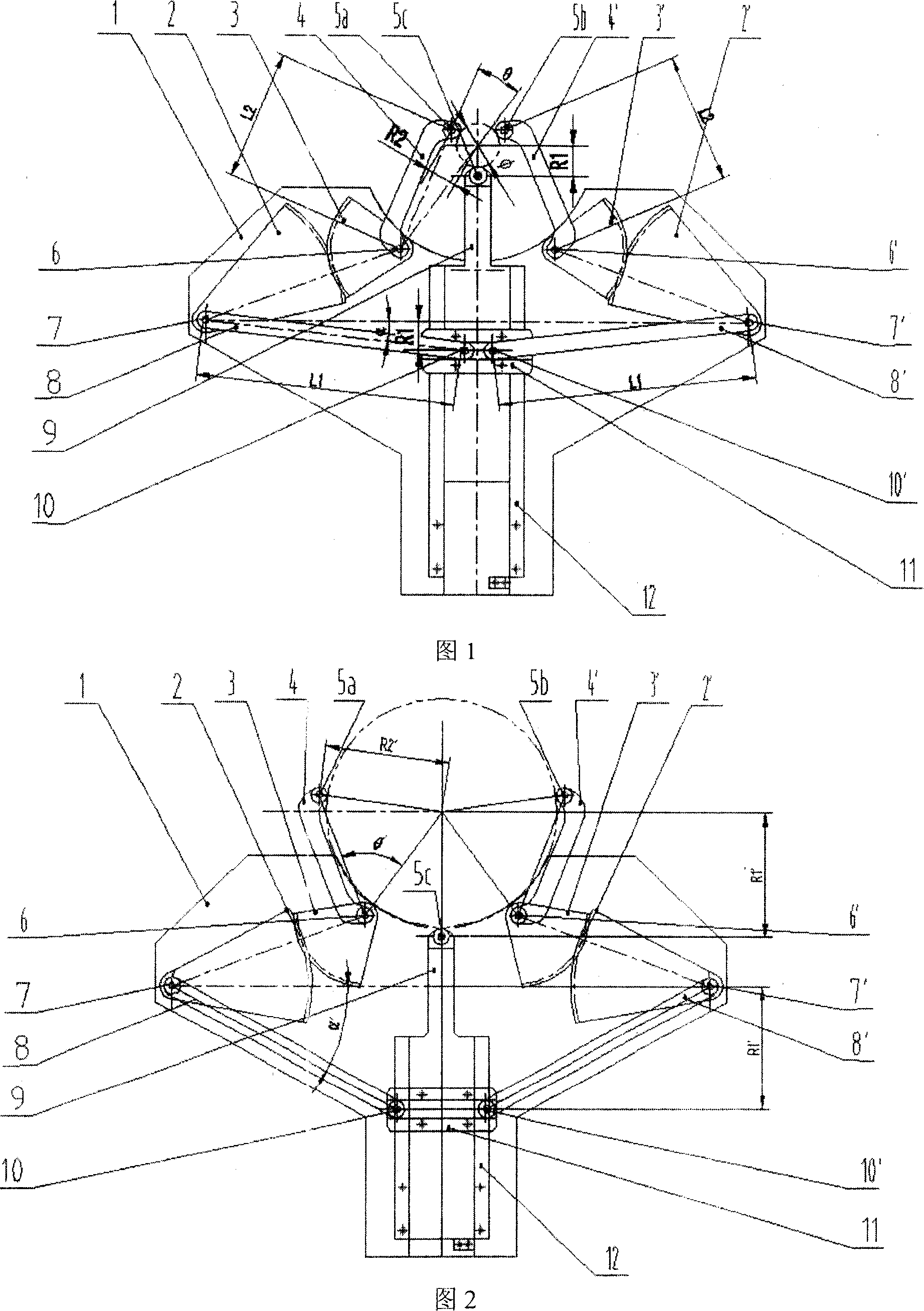

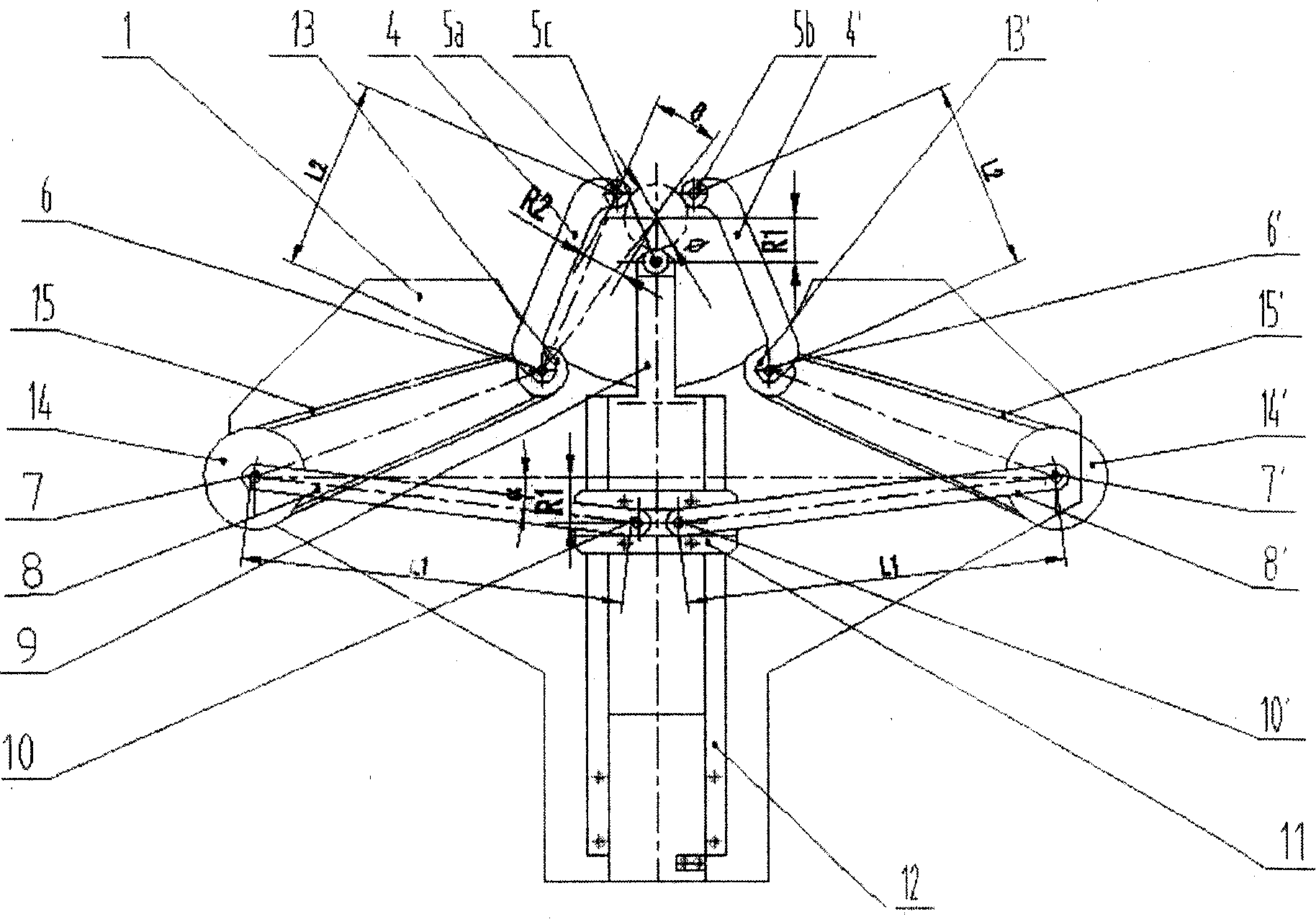

[0012] As shown in FIG. 1 , the lower pressing rod slide rail 12 is fixed on the middle part of the bracket 1 , and the lower pressing rod 9 is located on the lower pressing rod sliding rail 12 and can slide up and down along the lower pressing rod sliding rail 12 . A chute block 11 is installed on the lower pressing rod 9 . The left large sector gear 2 is fixedly connected to the left connecting rod 8, and is connected to the bracket 1 through the left lower rotary pin 7, and the right large sector gear 2' is fixedly connected to the right connecting rod 8', and is connected to the bracket 1 through the right lower rotary pin 7' Up, can rotate around left and right lower rotary pins 7,7' respectively. The lower left rotary pin 7 and the lower right rotary pin 7' are symmetrically arranged on the support 1 relative to the lower bar slide rail 12. One end of left connecting rod 8, right connecting rod 8 ' is installed on the support 1 by lower left rotary pin 7, lower right ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com