Method for reconstructing operation platform column foundation in existing workshop

A technology for operating platforms and column foundations, which is applied in the repair of foundation structures, foundation structure engineering, building construction, etc., can solve the problems of large construction work volume, insufficient utilization, and long construction period, so as to shorten the construction period and avoid Effect of uneven foundation settlement and reduction of construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

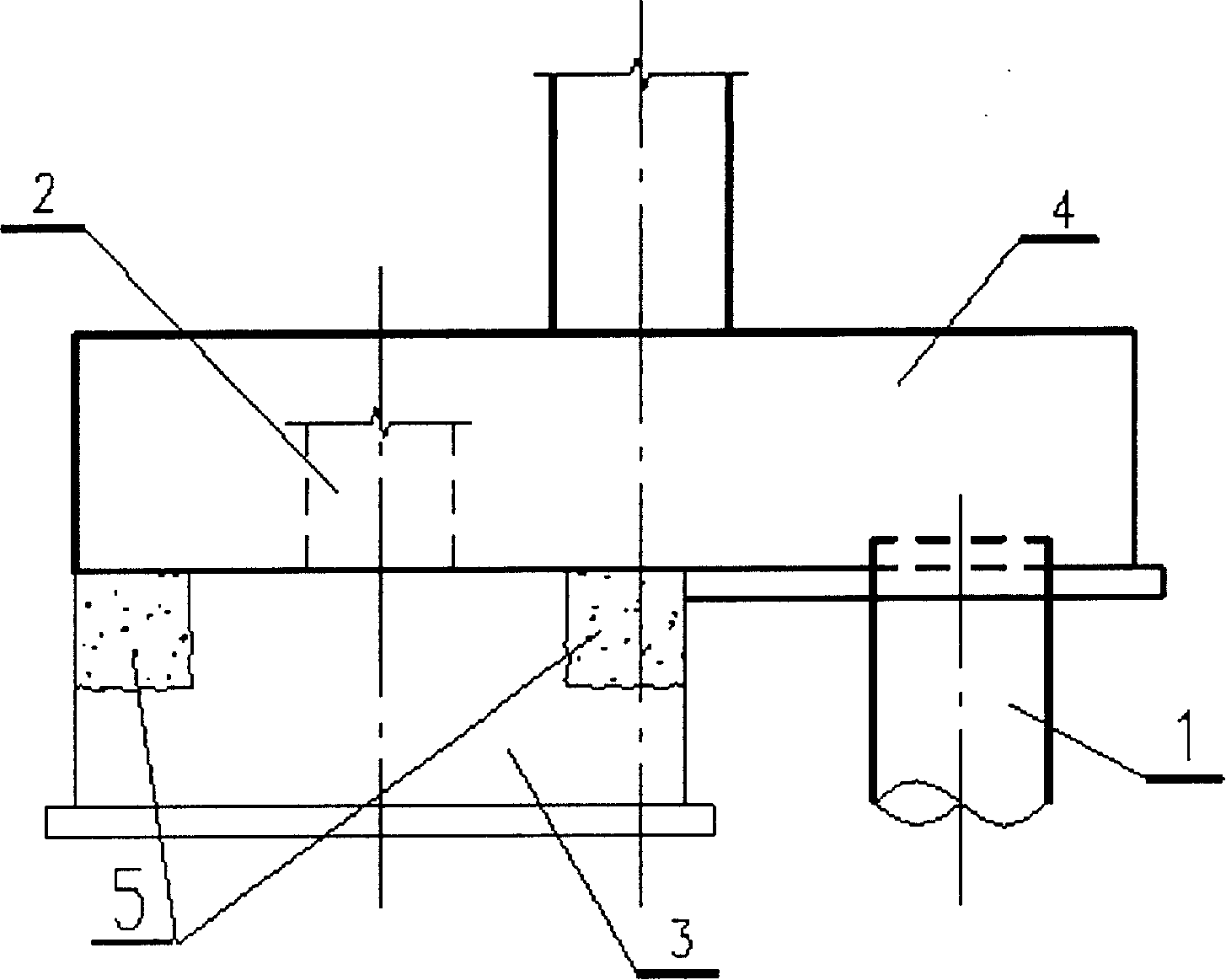

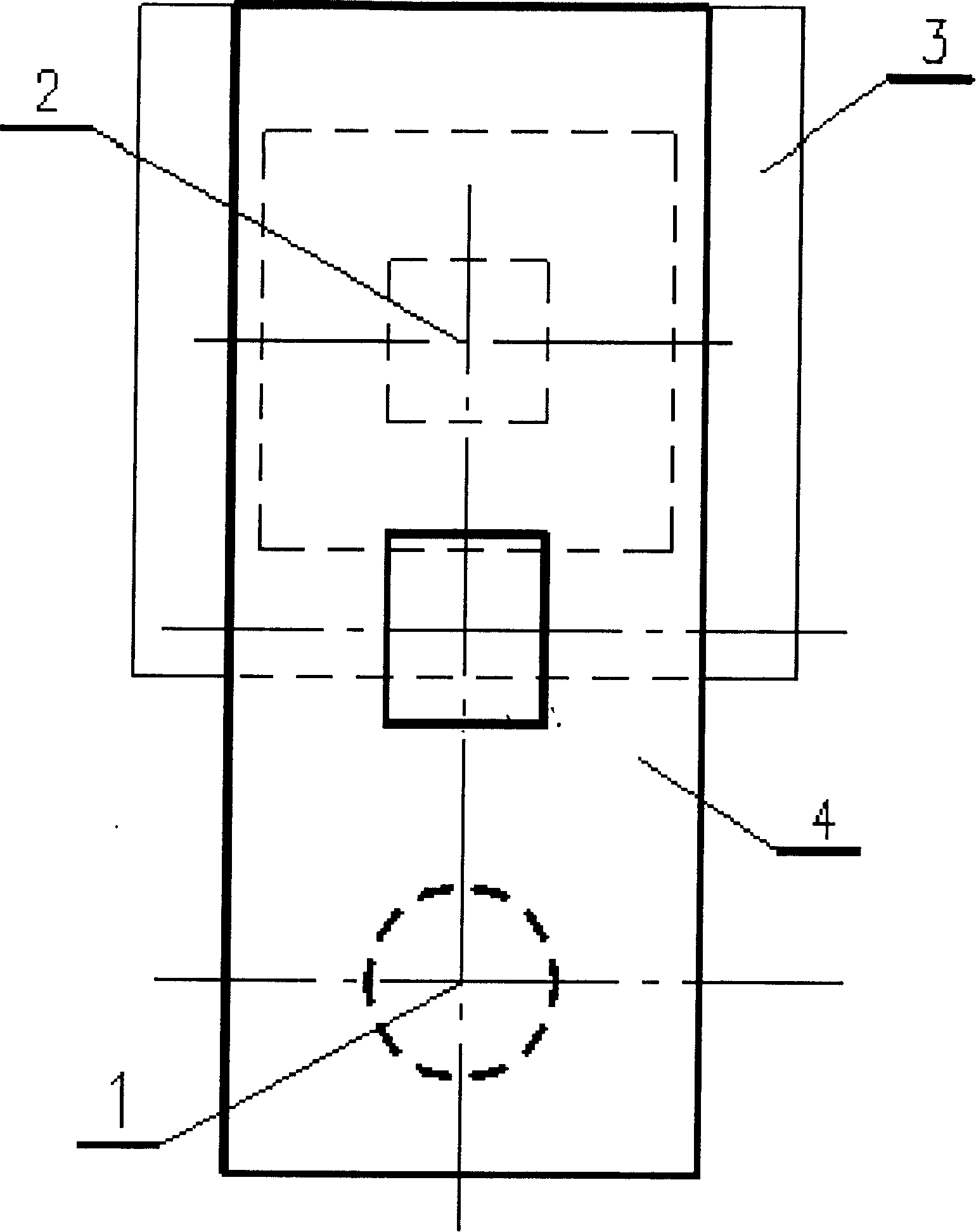

[0010] Further illustrate the embodiment of the present invention below in conjunction with accompanying drawing: when making new operation platform post foundation in original factory building, keep old operation platform column foundation or equipment foundation 3 in original factory building unchanged, according to the new of required making The size and design position of the operation platform column foundation 4 determine the construction of the new operation platform column foundation pile 1 near the old operation platform column foundation, and carry out the construction of the new operation platform column foundation pile 1 according to the traditional foundation pile manufacturing method , the height of the new operation platform column foundation pile 1 is manufactured according to the design elevation, so that the new operation platform column foundation pile 1 is embedded in the bedrock or placed on the bearing layer that meets the design requirements, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com