Structure capable of preventing concrete face slab dam high-toe wall from being damaged

A technology for concrete face dams and concrete seepage prevention walls, which is applied in infrastructure engineering, dams, barrages, etc., can solve the problems of large excavation volume, large passive earth pressure, and difficult toe line layout, and avoid large excavation. , the effect of saving construction period and project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

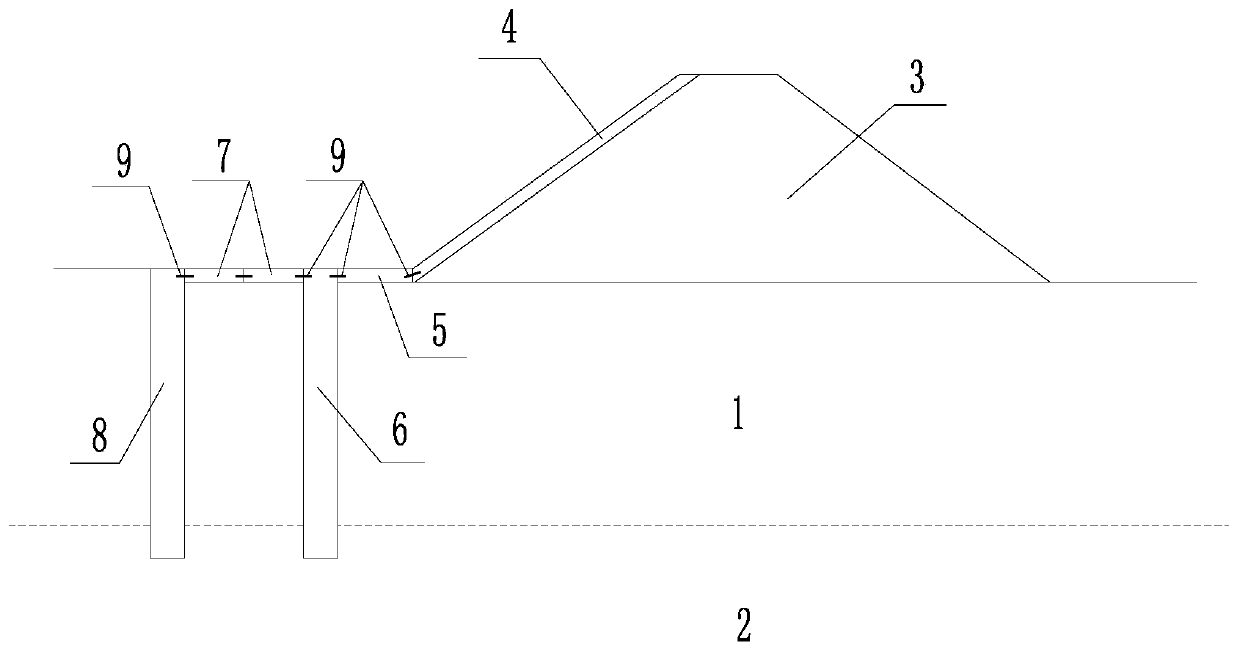

[0013] Such as figure 1 As shown, the structure of the present invention to prevent the damage of the high toe wall of the concrete face dam includes the concrete face dam 3 built on the deep covering layer 1, the face plate 4 arranged on the upstream face of the concrete face dam 3, and the expansion of the face plate 4 and the dam foot. Panel 5, the high toe wall 6 that is set before expanding panel 5, between expanding panel 5 and anti-seepage wall 6, between expanding panel 5 and panel 4, all be provided with waterstop 9, on the upstream side of high toe wall 6 also The anti-seepage wall 8 is set, the connecting plate 7 is arranged between the high toe wall 6 and the anti-seepage wall 8, the high toe wall 6, the anti-seepage wall 8 and the connecting plate 7 are connected by a water stop 9, the high toe wall 6 and the anti-seepage The seepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com