Metal tube circular moulded sealing washer and its manufacturing method

A technology for sealing gaskets and manufacturing methods, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as limited pressure resistance and compression rebound performance, loss of sealing performance, poor sealing performance, etc. The effect of wide stress range and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

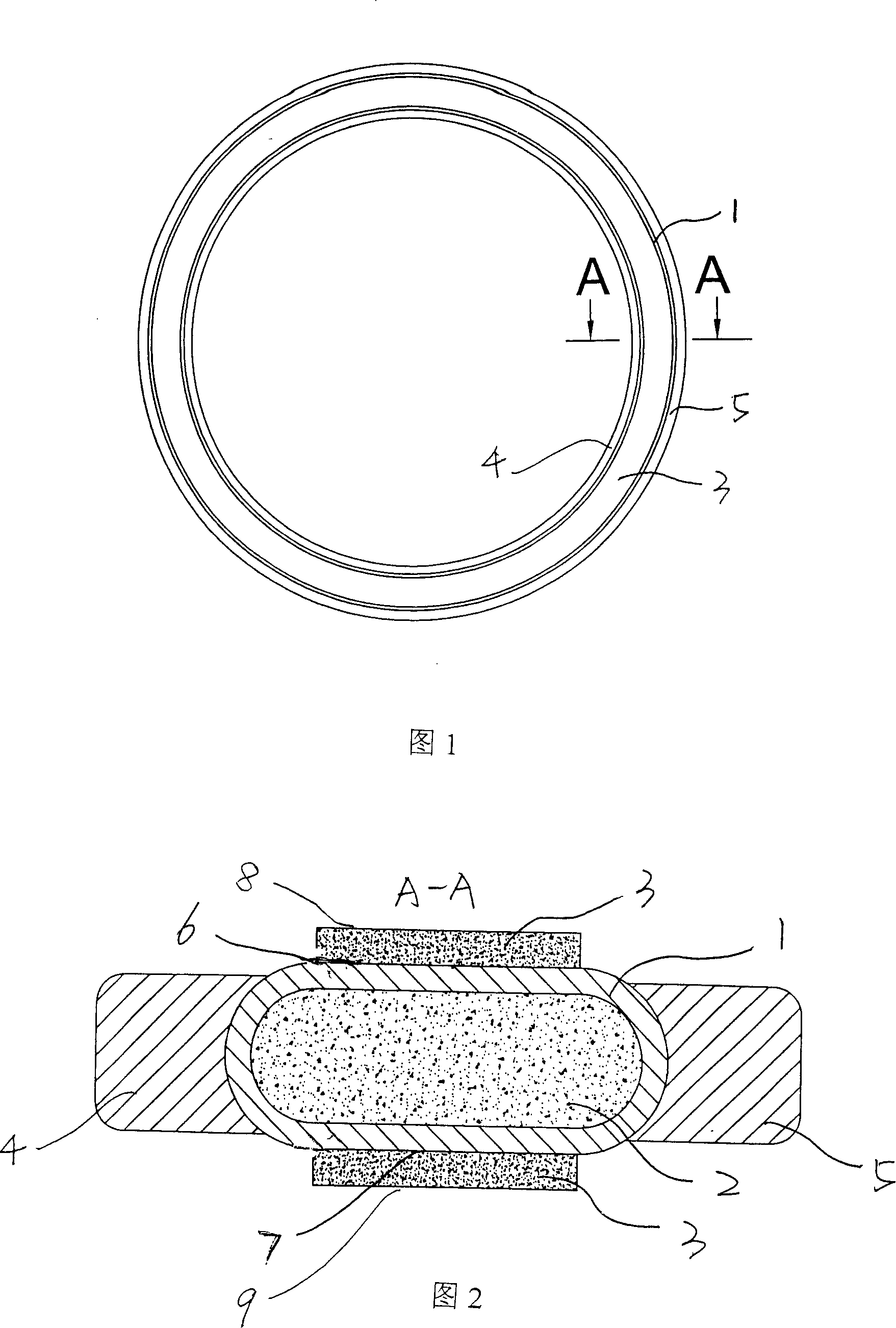

[0015] Referring to the metal pipe ring molded sealing gasket shown in accompanying drawings 1 to 2, it includes an annular metal pipe 1, a flexible sealing filler 2 filled in the metal pipe 1, and the metal pipe 1 The upper and lower outer surfaces of the upper and lower surfaces are respectively provided with cladding 3, the inner side of the metal pipe 1 has a ring-shaped restricted inner ring 4, and the outer side of the metal pipe 1 has a restricted outer ring 5, and the metal pipe 1 is clamped Immediately between the restriction inner ring 4 and the restriction outer ring 5, the metal pipe 1, the restriction inner ring 4 and the restriction outer ring 5 are arranged concentrically. The metal pipe 1 is made of materials such as carbon steel, stainless steel, copper, aluminum, Monel, Inconel, titanium, etc., and the flexible sealing filler 2 is a non-metallic material, such as graphite, fiber, A mixture of one or more than two types of polytetrafluoroethylene, the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com