Reboiler for material of high viscosity,high solidifying point and intensified heat sensitivity

A heat-sensitive material and high freezing point technology, applied in boiling devices, chemical instruments and methods, hydrocarbon distillation, etc., can solve problems such as intensified carbonization or puffing, abnormal operation, and reduced heat transfer effect, so as to improve fluidity and shorten The effect of residence time and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

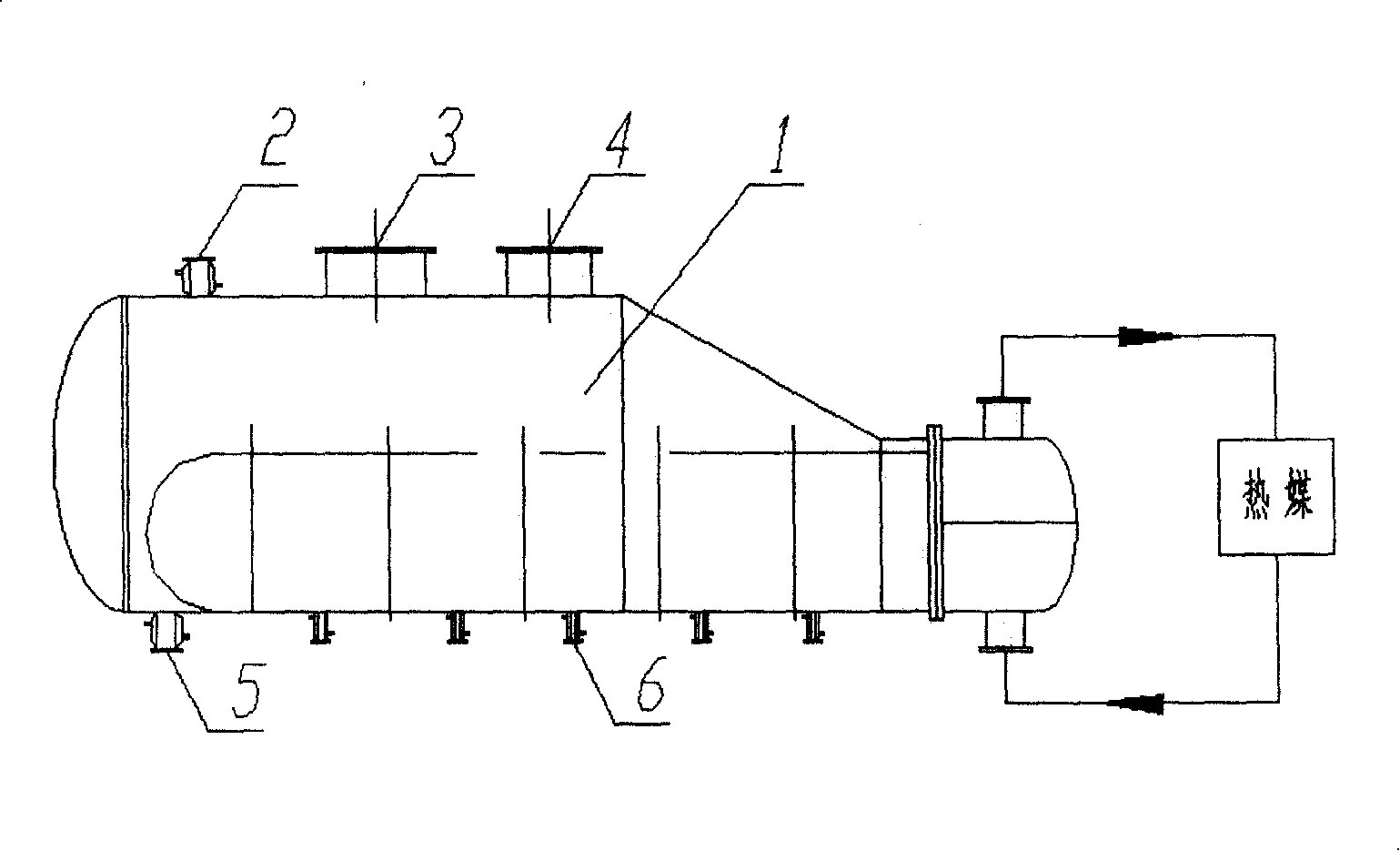

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

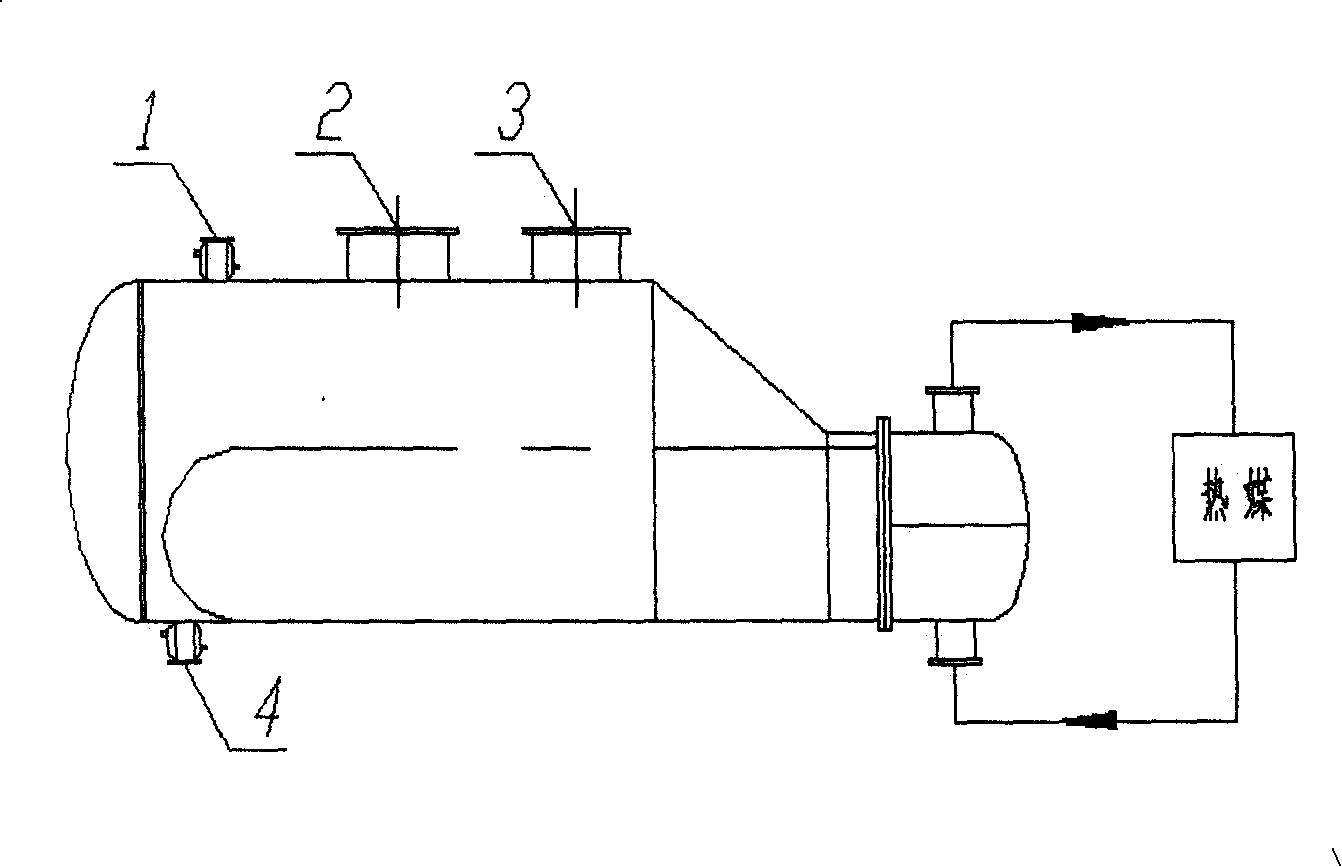

[0009] Such as figure 2 Shown is a reboiler for materials with high viscosity, high freezing point and strong heat sensitivity according to the present invention, which includes a kettle body 1 and a plurality of heat exchange tubes arranged in the kettle body, and a material inlet 2 is respectively arranged on the top of the kettle body , gas outlet 3, manhole 4, a material outlet 5 is arranged at the bottom of the kettle body, and it also includes a plurality of material inlets 6 arranged at the bottom of the kettle body. For the reboiler design of high-viscosity materials, the heat exchange tubes are arranged with a super large tube spacing 2d≤t≤3d (d is the outer diameter of the heat exchange tubes), and the centrifugal pump or gear pump is used to increase the circulation flow. Add multiple circulating material inlets to speed up mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com