Catalyst for producing alkyl benzene

A catalyst and alkylbenzene technology, applied in the field of catalysts for the production of alkylbenzene, can solve problems such as high reaction temperature, high benzene-to-hydrocarbon ratio, and low olefin space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 1500 grams of water glass (modulus = 2.8) with 500 grams of hexamethyleneimine evenly, mix 50 grams of sodium aluminate and 25 grams of sodium hydroxide in 500 grams of water, and stir the above two solutions vigorously Mix evenly, continue to stir for 2 hours, add 500 g of water and stir for 1 hour, age the above mixed solution at 10°C for 100 hours to form a jelly, and set aside.

Embodiment 2

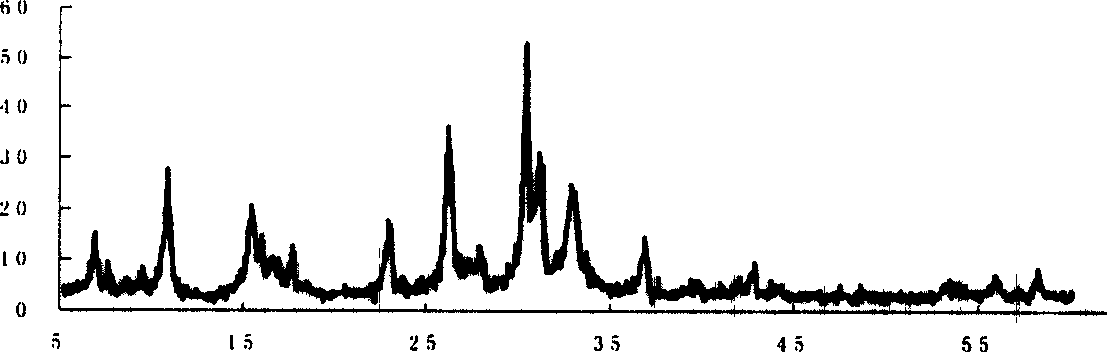

[0031] Dissolve and mix 25 grams of sodium aluminate and 20 grams of sodium hydroxide in 500 grams of water, add 500 grams (40% by weight) of colloidal silica and stir, then add 800 grams of pure water and stir and mix, add the mixture prepared in Example 1 50 g of sol was transferred to a crystallization tank after continuing to stir for 2 hours, stirred and crystallized at 165°C for 100 hours, filtered and washed until pH = 8, and dried at 150°C. The specific surface area of the obtained sample was 550 m 2 / g, the pore volume is 0.5 ml / g, the XRD diffraction data are shown in Table 1, and the XRD diffraction pattern is as follows figure 1 shown.

[0032] Table 1 XRD diffraction data

[0033] 2θ diffraction angle

[0034] Take 100 grams of the crystalline aluminosilicate material synthesized above, add 0.5 mol / L ammonium nitrate solution, heat up to 95°C for 2 hours, and repeat the exchange 6 times, so that the alkali metal ion content in the crystalline alumino...

Embodiment 3

[0036] The catalyst prepared in Example 2 was pulverized into 20-60 mesh particles, and 1.0 g of the catalyst was carried out in a fixed-bed reactor for liquid-phase alkylation of propylene. The reaction conditions were: propylene space velocity=1.5 hours -1 , reaction temperature=140 DEG C, reaction pressure=2.5MPa, reaction product is cumene, propylene conversion rate=100%, product selectivity 99.2%, total benzene / olefin molar ratio is 2.1, no catalyst activity is observed in reaction 2000 hours loss, the export cumene concentration reaches 44%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com