Central-mounted single-stage and multi-stage double-suction turbine synchronous suction and discharge pump

A technology of exhaust-suction pump and turbine, which is applied in the field of double-suction synchronous exhaust-suction pump of split-stage double-suction turbine, can solve the problems of high infrastructure cost, difficult maintenance, short circuit of motor, etc. The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

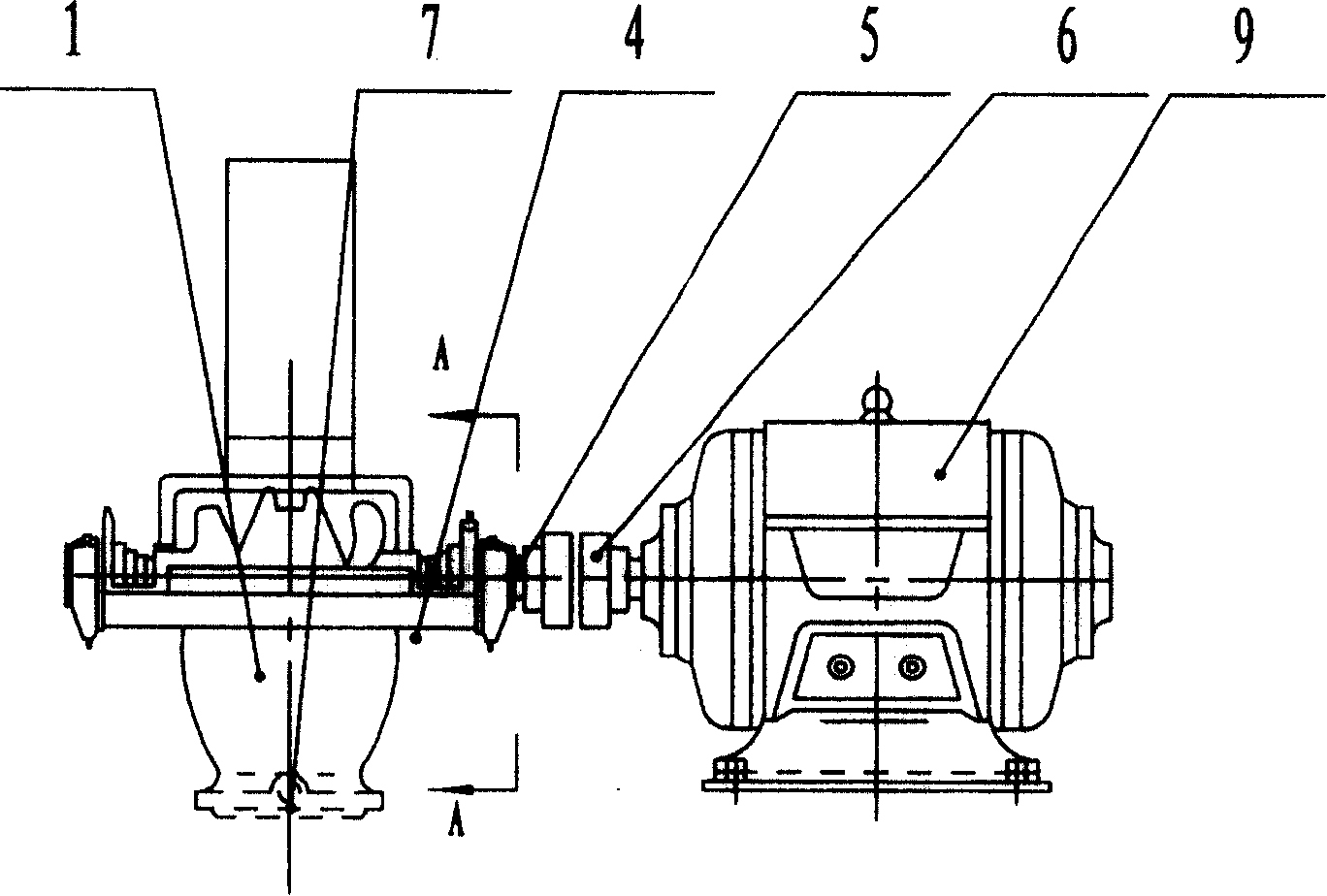

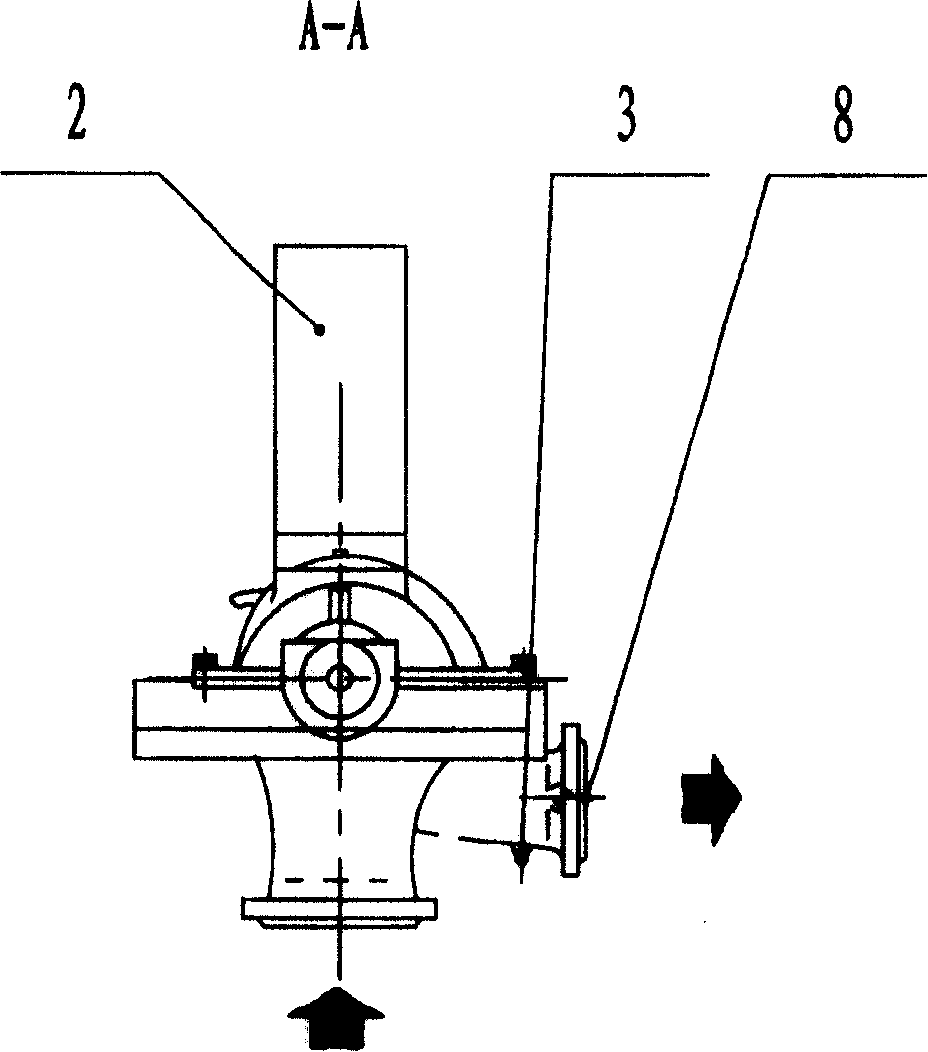

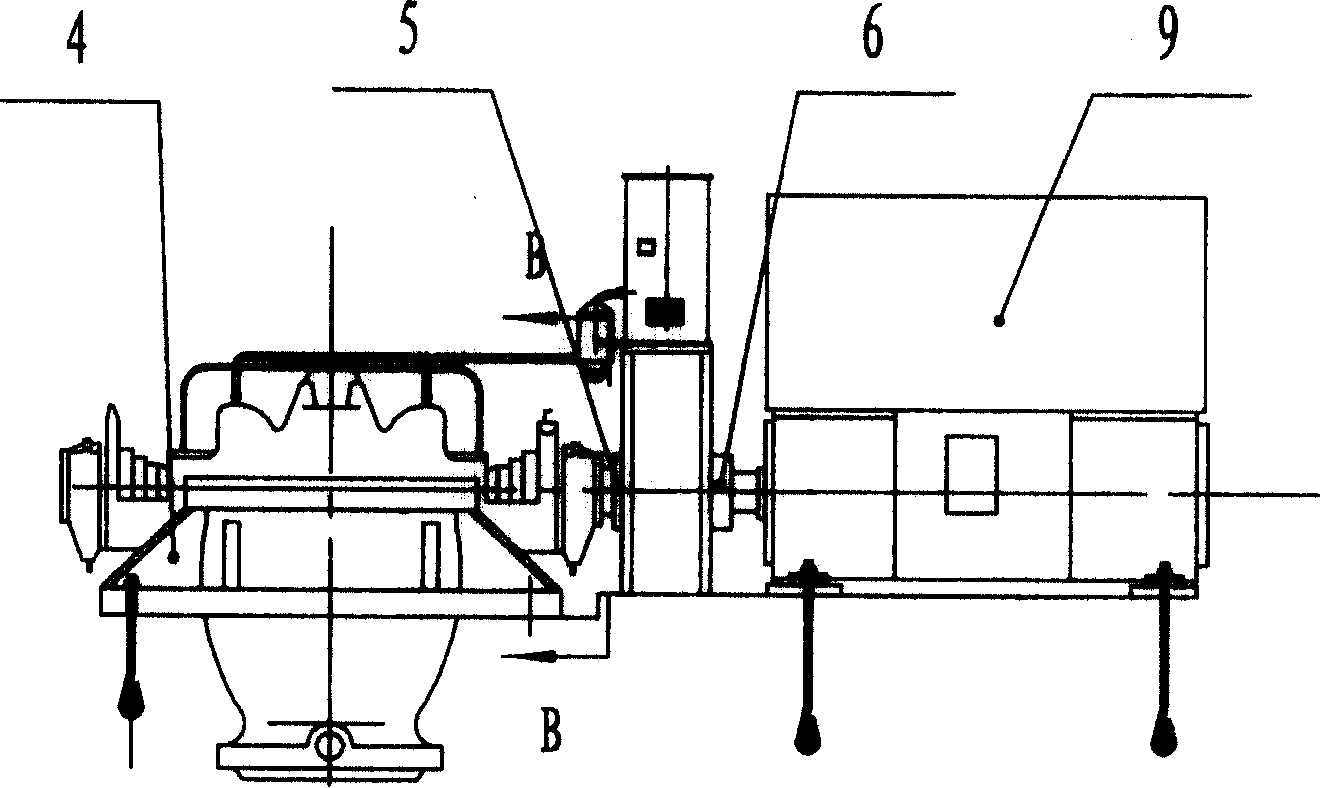

[0024] Split double suction turbine synchronous exhaust suction pump, including pump body 1, turbine fan 2, and air release valve 3. The suction port 7 of the pump body 1 is upward, and the pump body 1 is perpendicular to the axis of the center opening. Four support feet 4 are provided on the lower end surface of the split flange of the pump body 1 to realize central support or central lower support. A turbo fan 2 is arranged on the top of the pump body 1 , and the suction port of the turbo fan 2 communicates with the suction chamber of the pump body 1 . An air release valve 3 is installed on the outlet of the pump body 1 . During assembly, the suction port 7 of the pump body 1 lies below the ground, and the four supporting feet 4 are supported by corresponding I-beams. The outlet of the pump body 1 is connected with the outlet pipe through the flange 8, and the pump shaft 5 is connected with the shaft of the motor 9 through the shaft coupling 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com