Testing device for density variable printed circuit board

A technology of printed circuit boards and test devices, which is applied in the field of test devices that can increase the density of probes, can solve the problems of invariable density and difficulty in testing printed circuit boards, and achieve the effect of increasing test density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

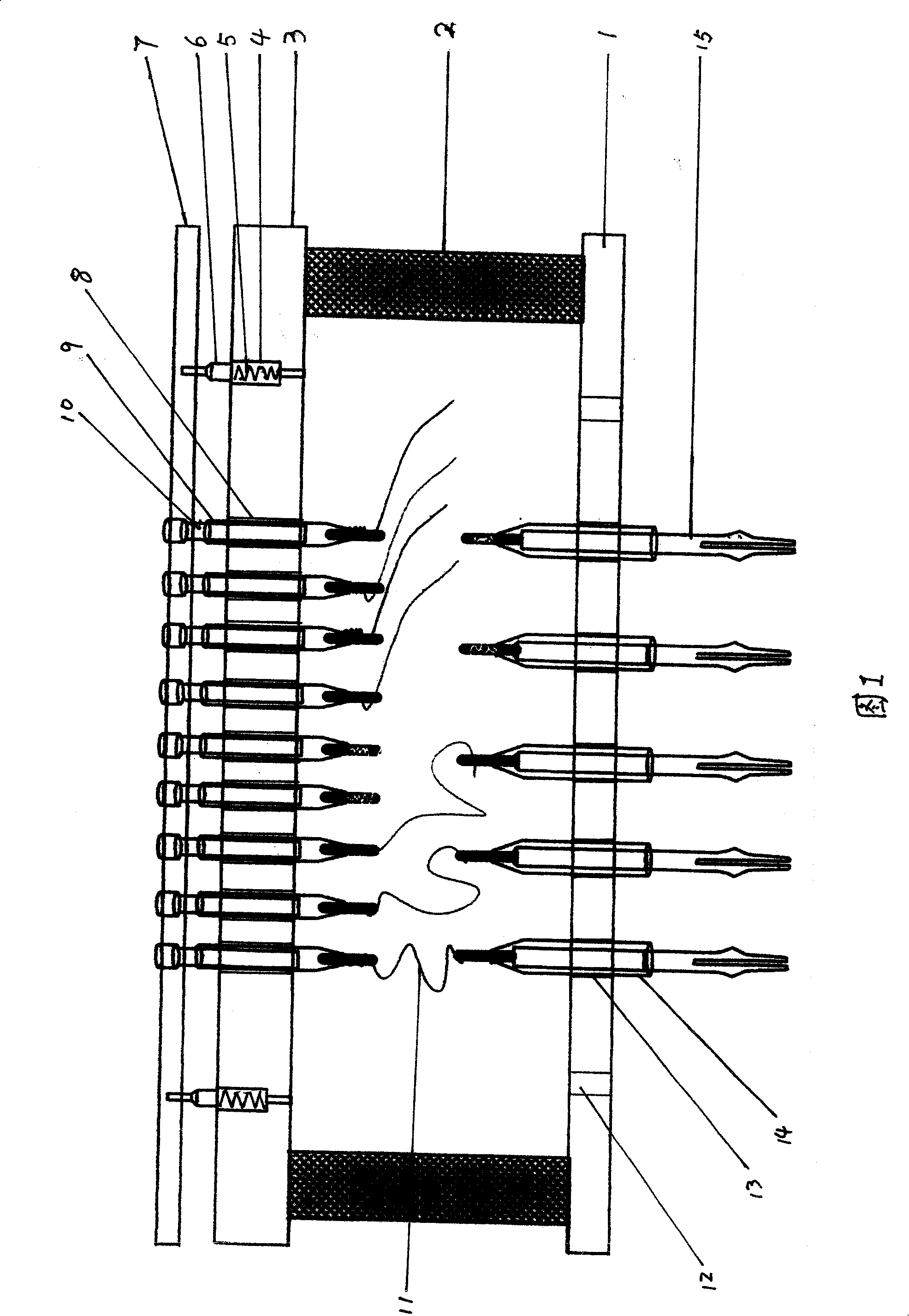

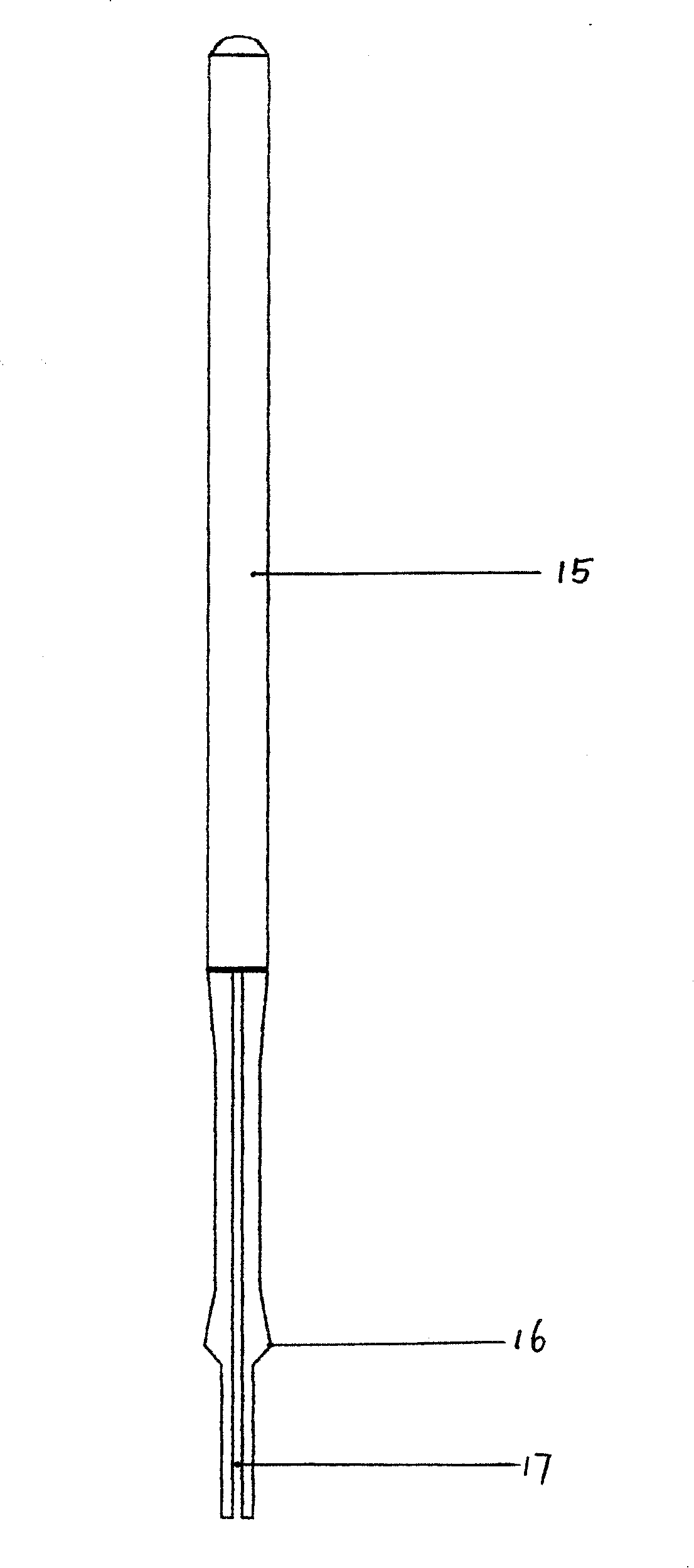

[0011] As shown in Figure 1, this device is used with a printed circuit board testing machine. Place the device on the testing machine, align the positioning hole 12 with the positioning shaft of the testing machine and press down, and the positioning hole 12 will fit on the positioning shaft of the testing machine. , There are at least two positioning holes, so that the device can be positioned accurately. At the same time, the lower end of the transfer terminal 15 is inserted into the sleeve on the testing machine. The upper end of the transfer terminal sleeve 14 is wound with the wire 11, and the other end of the wire 11 is wound with the lower end of the probe sleeve 9, and the connection of the wire 11 is selectively connected according to the test requirements. During the test, the printed circuit board is placed on the upper end of the protection board 7, and the probes 10 are brought into contact with the test points of the printed circuit board, so as to test the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com