Wafer grinding device and method

A wafer and grinding technology, applied in the direction of grinding/polishing safety device, grinding device, grinding/polishing equipment, etc., can solve the problems of adhesive peeling, thickness measurement accuracy reduction, wafer thickness error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

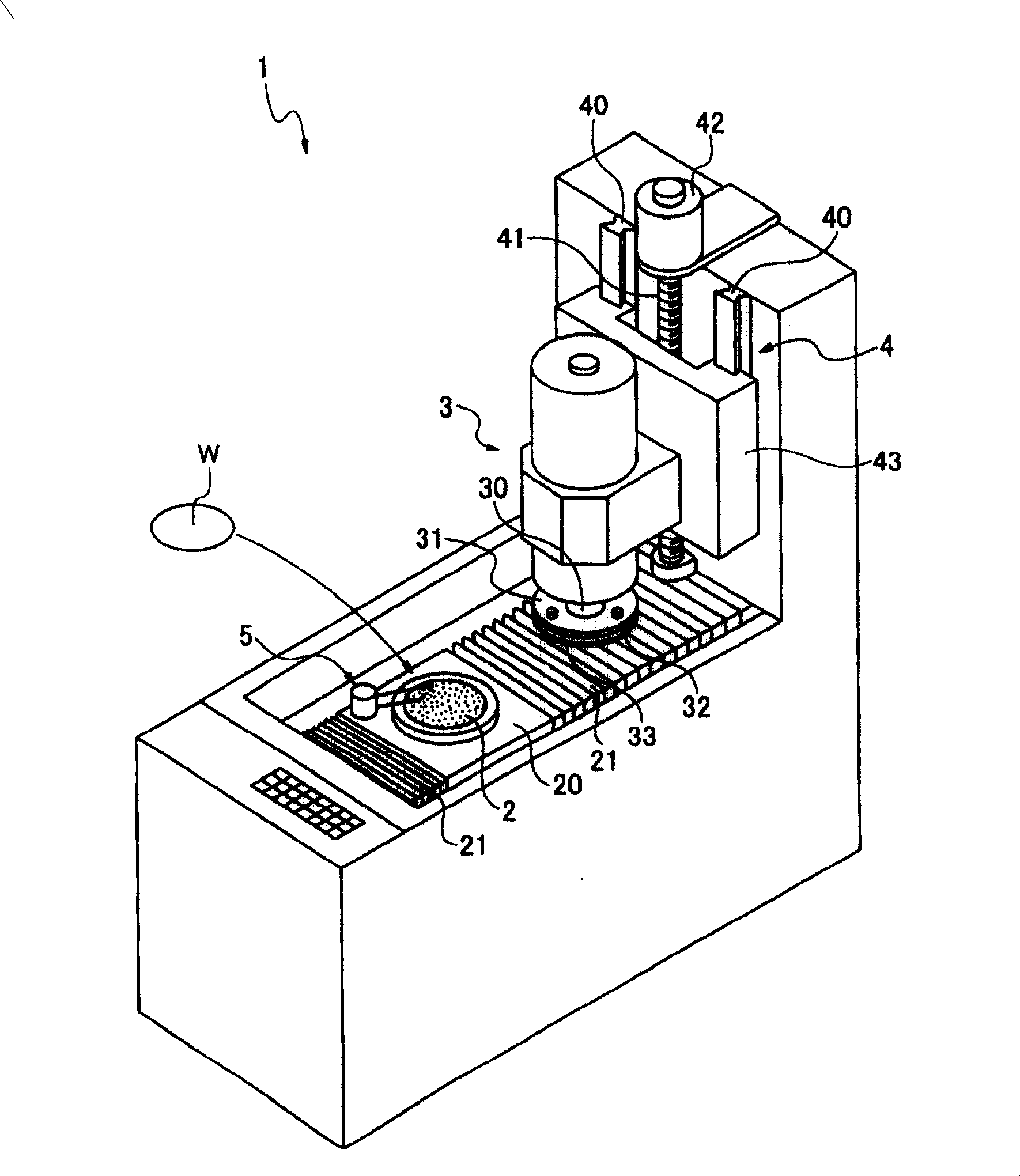

[0018] As an example of the present invention, the figure 1 The shown grinding apparatus 1 and a method of grinding a wafer W using this grinding apparatus 1 will be described.

[0019] The grinding device 1 has a chuck table 2 capable of holding the wafer to rotate, and a grinding mechanism 3 for grinding the ground wafer held on the chuck table 2 , and the grinding mechanism 3 is raised and lowered by a drive mechanism 4 .

[0020] The chuck table 2 is rotatably supported by the movable base 20, and the movable base 20 moves in the horizontal direction as the rack 21 expands and contracts, and at the same time, the chuck table 2 also moves in the same direction.

[0021] The grinding mechanism 3 has a main shaft 30 with a vertical axis, a fixing device 31 formed at the lower end of the main shaft 30 , a grinding wheel 32 fixed on the fixing device 31 , and a grinding wheel 33 is installed below the grinding wheel 32 . The grinding wheel 33 is formed by fixing abrasive grai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com