Backlight module

A backlight module and backplane technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of shortening the operating life and reducing the luminous efficiency of light-emitting diodes, and achieve the effect of increasing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

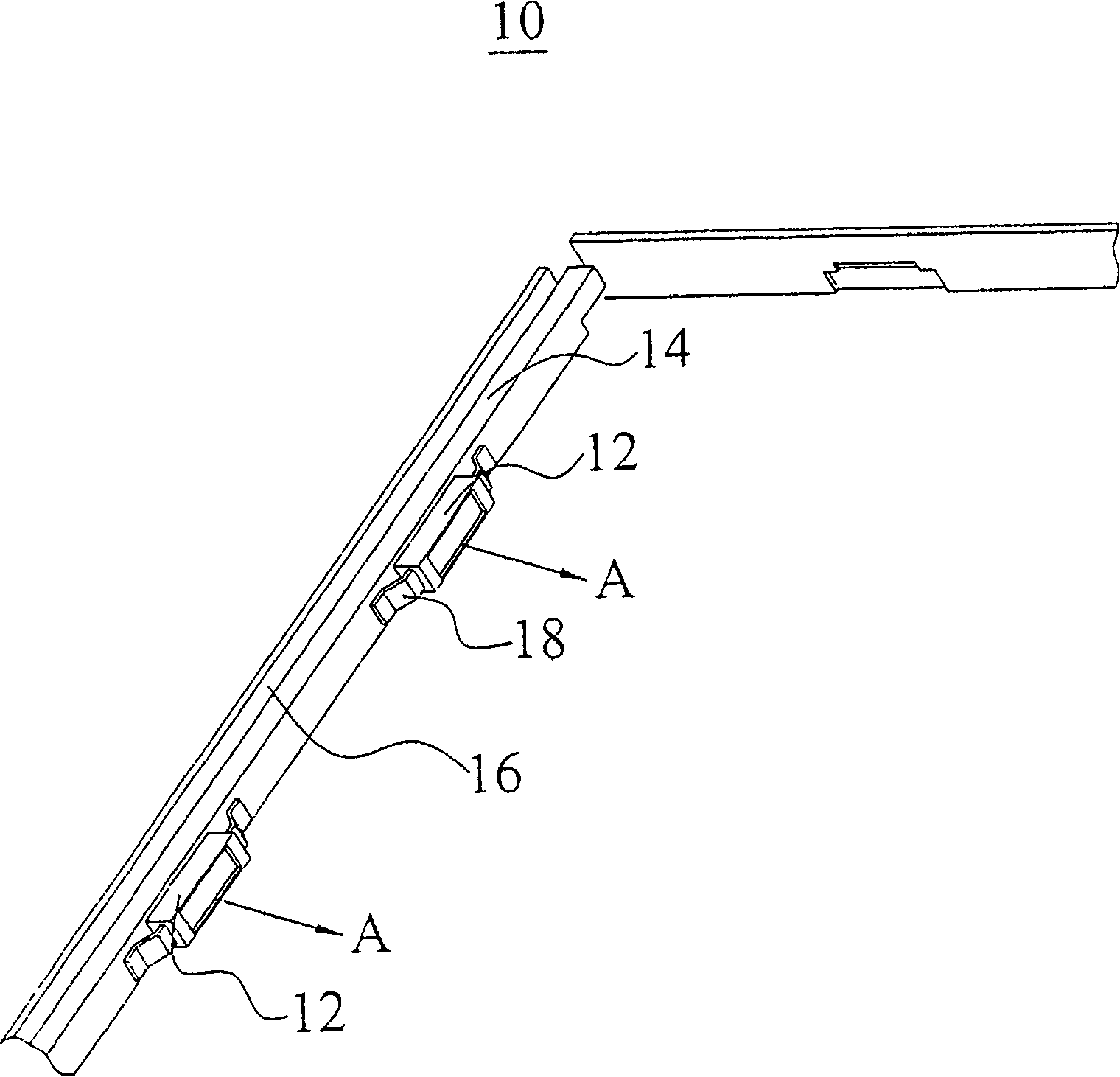

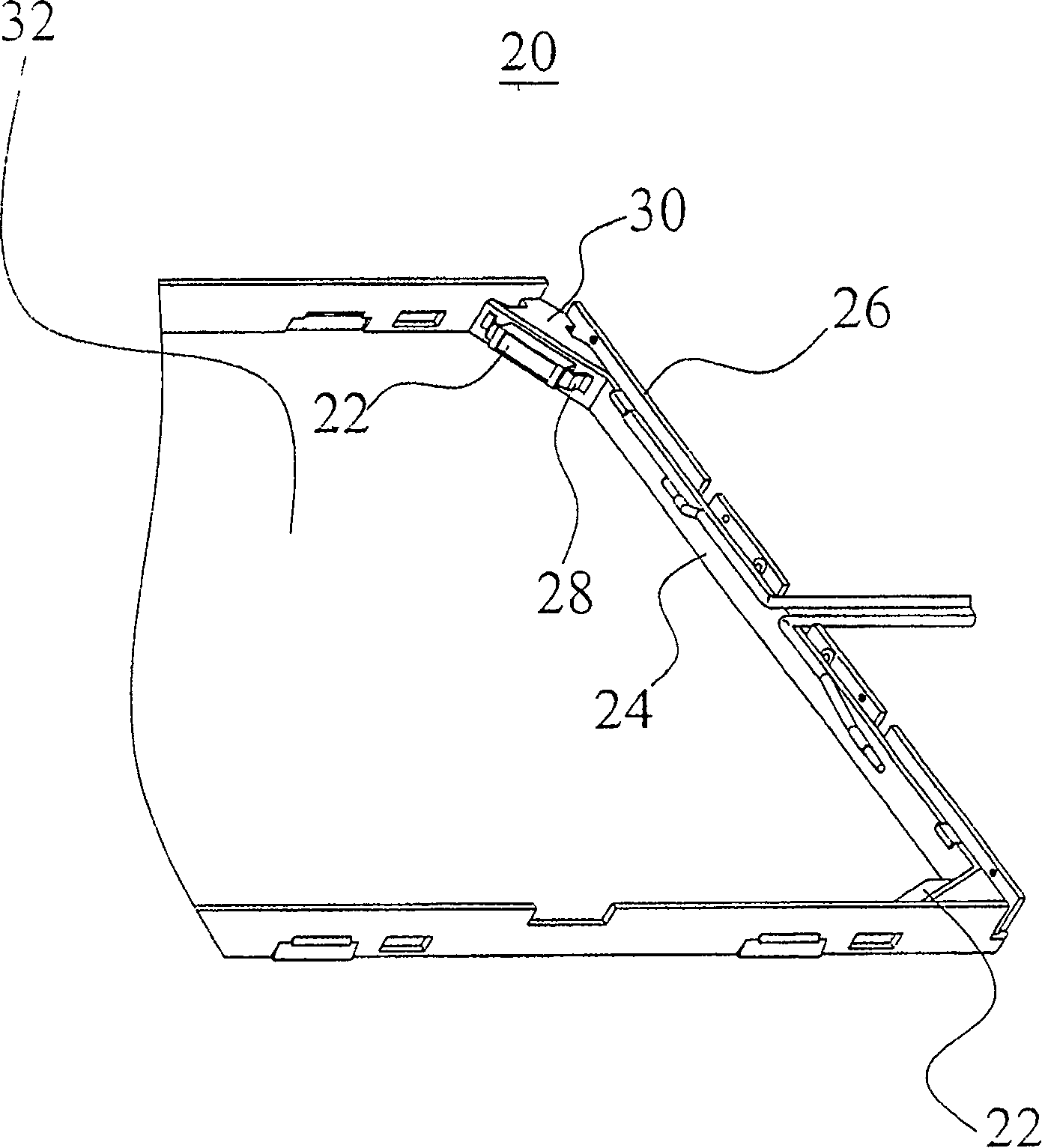

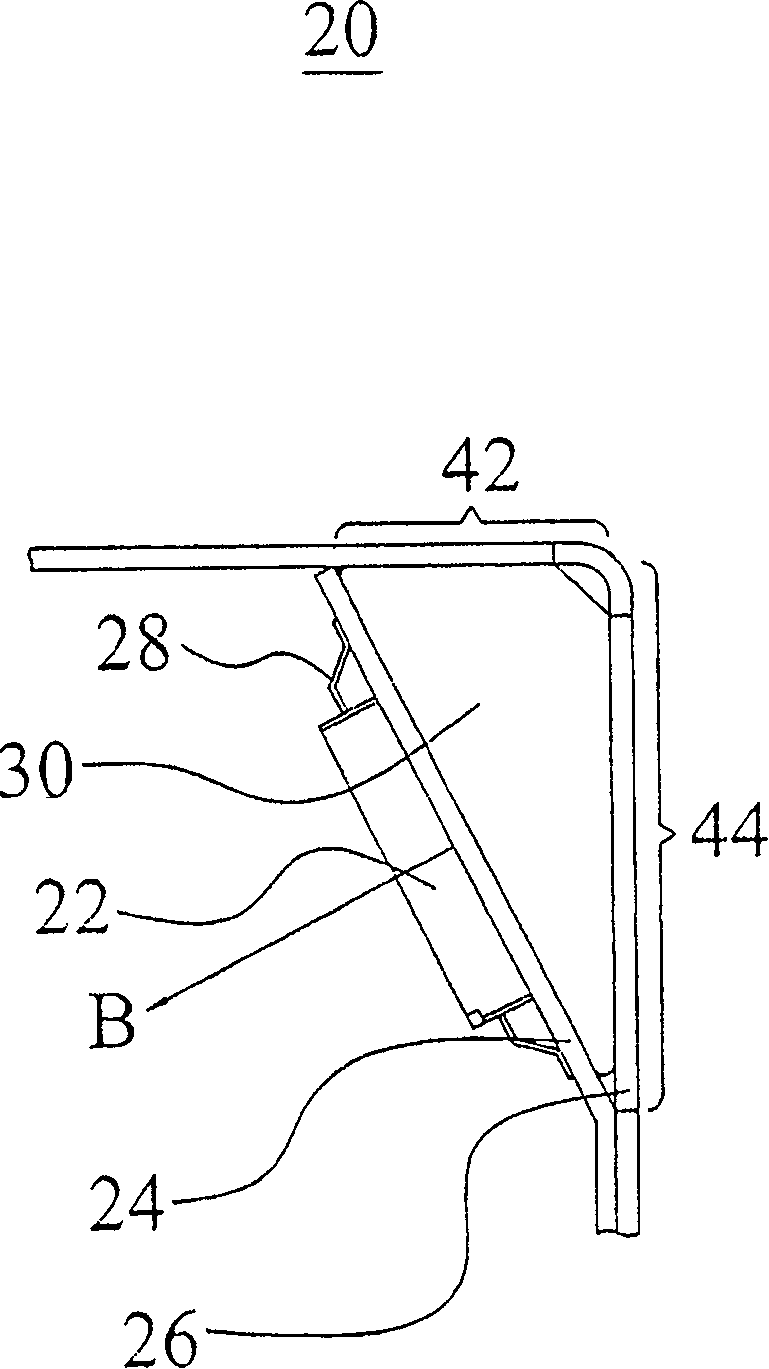

[0019] see figure 2 as well as image 3 , figure 2 is a structural diagram of the backlight module 20 of the present invention, image 3 It is a partial top view of the backlight module 20 of the present invention. The backlight module 20 includes a bezel 26 , and a light emitting diode (LED) 22 is disposed at a corner of the bezel 26 . The bottom surface 32 of the back plate 26 is used to arrange optical elements including a light guide plate, a diffusion sheet, a prism sheet (Brightness Enhancement Film) and the like, which are not shown here to simplify the drawings. These elements are shown. In addition, the LEDs 22 are disposed on a circuit board 24 , and a heat conduction block 30 is disposed between the circuit board 24 and the back plate 26 . The heat conducting block 30 and the back plate 26 can be made of metal (such as aluminum) or other materials with high thermal conductivity.

[0020] When the driving circuit (not shown) of the LED 22 drives the LED 22 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com