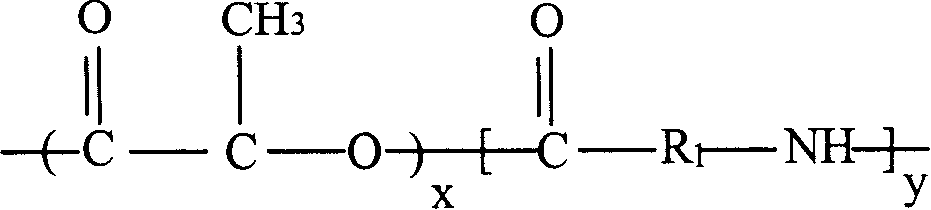

Method for preparing L-lactic acid and amino acid copolymer by melt-solid phase condensation polymerization

A technology of amino acids and copolymers, which is applied in the field of modified polylactic acid and its preparation, can solve the problems of high cost and complicated process, and achieve the effect of convenient operation, simple process and widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Measure 700mL 85% L-lactic acid (Purac company product) in a 1000mL single-necked round bottom flask, place the flask on a rotary evaporator, the rotating speed of the rotary evaporator is 200rpm / min, heat in an oil bath at 130°C, and gradually reduce the pressure to a pressure less than 1.0×10 -3 MPa, continue dehydration for 4h and then stop. Fill with nitrogen to relieve the pressure, add 0.5% stannous octoate and 0.5% 6-aminocaproic acid after dehydration of the L-lactic acid mass, the temperature of the oil bath is raised to 180°C, the rotating speed of the rotary evaporator is still 200rpm / min, and the pressure is reduced gradually until the pressure is less than 5.0×10 -4 MPa, after 10 hours of reaction, add 0.5% stannous octoate, continue the reaction for 0.5 hours, finish the reaction and pour it into a stainless steel plate.

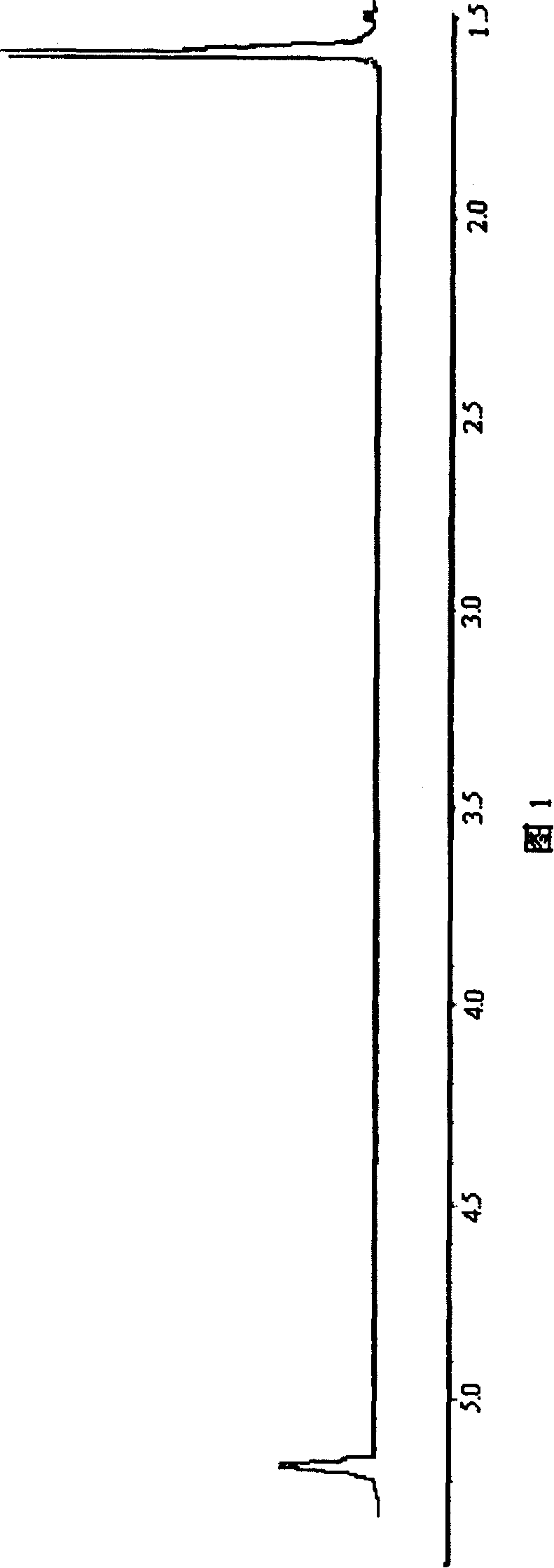

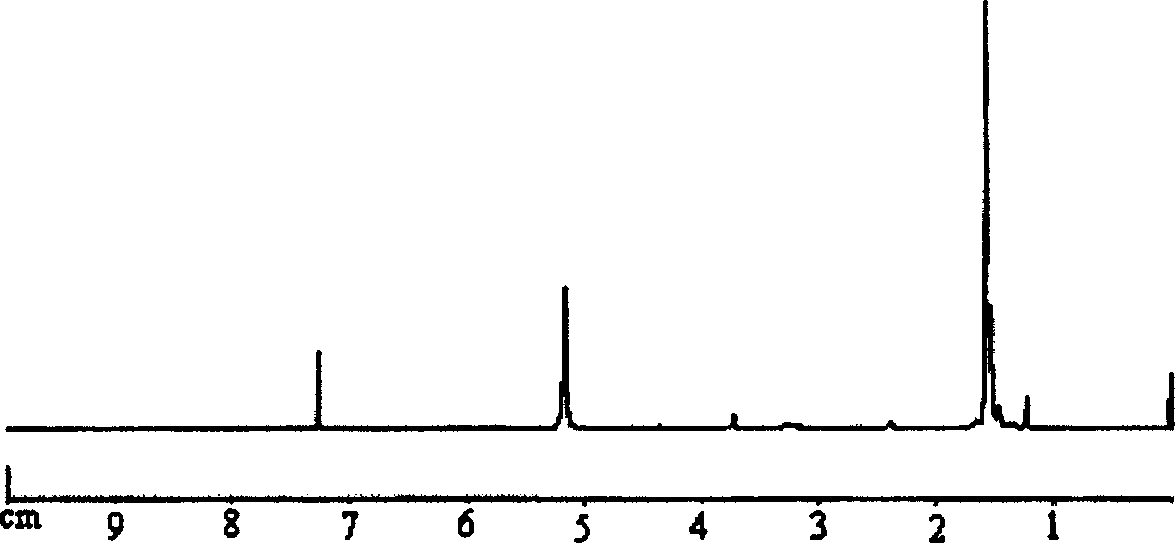

[0026] The above-mentioned prepolymer is pulverized and placed in a vacuum drying oven, and then put into 5 times the mass of the p...

Embodiment 2

[0030] The preparation of L-lactic acid prepolymer, and the condition of solid-phase polymerization are the same as embodiment 1,3-aminopropionic acid replaces 6-aminocaproic acid, and GPC method records the M of copolymer w 53,000.

Embodiment 3

[0032] The preparation of L-lactic acid prepolymer, and the condition of solid-phase polymerization are with embodiment 1,4-aminobutyric acid replaces 6-aminocaproic acid, and GPC method records the M of copolymer w to 56,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com