Square tubular screw rod transmission lifting lever

A lifting rod and lead screw technology, applied in the directions of transmission devices, electrical components, antenna parts, etc., can solve the problems of inconvenient stable operation of the lifting rod, large margin for left and right rotation, easy to cause danger, etc., and it is beneficial to achieve azimuth stability. , The effect of small azimuth movement margin and good azimuth stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

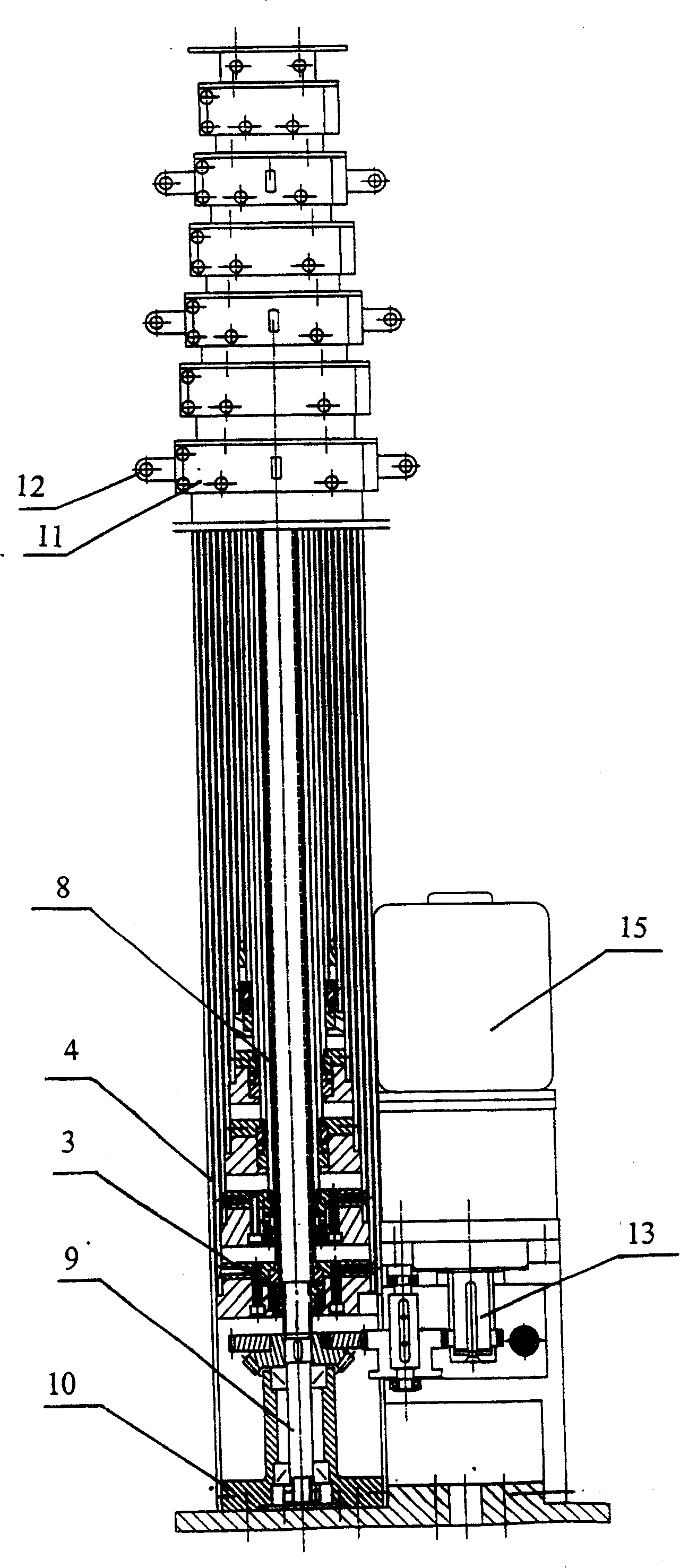

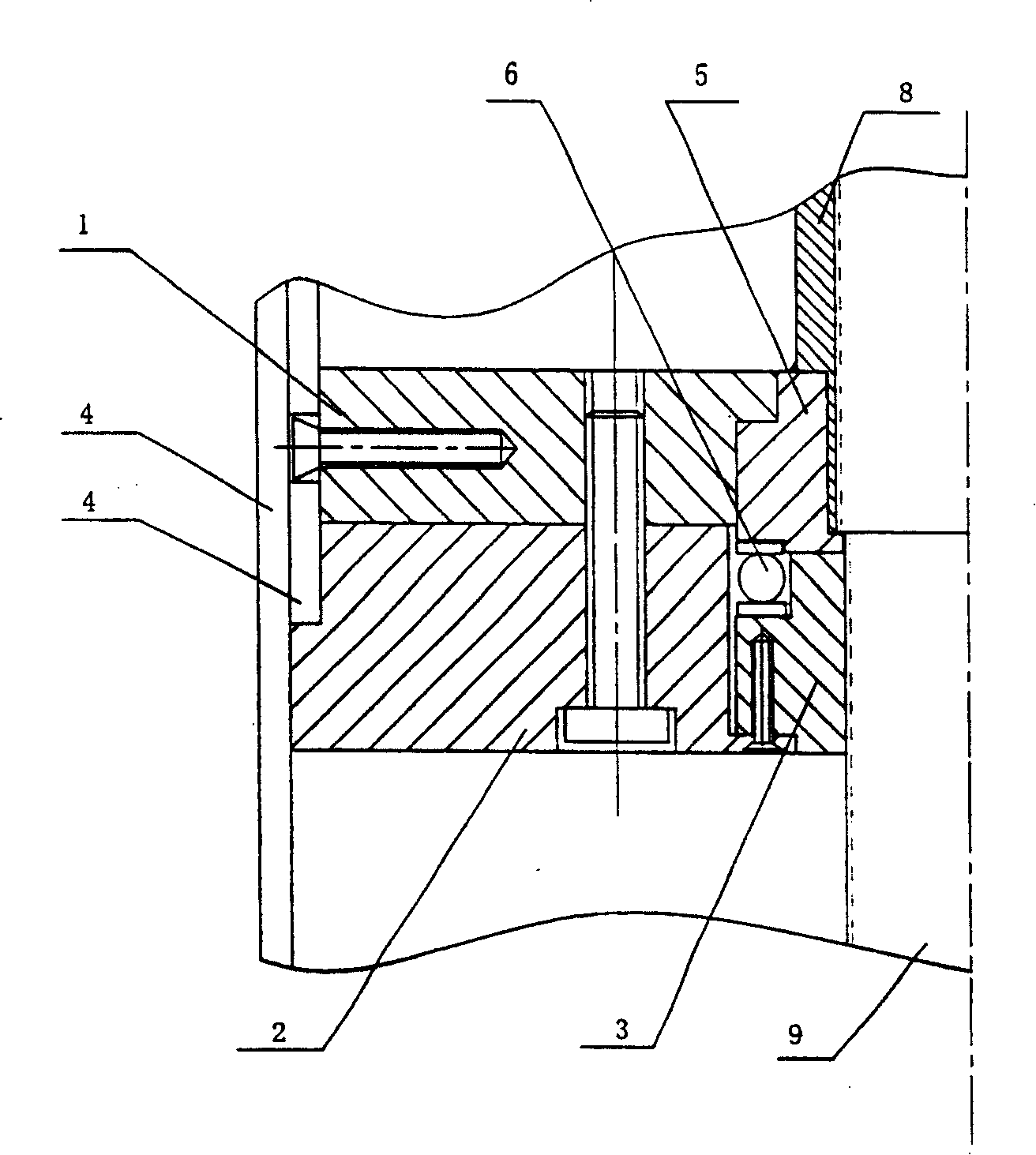

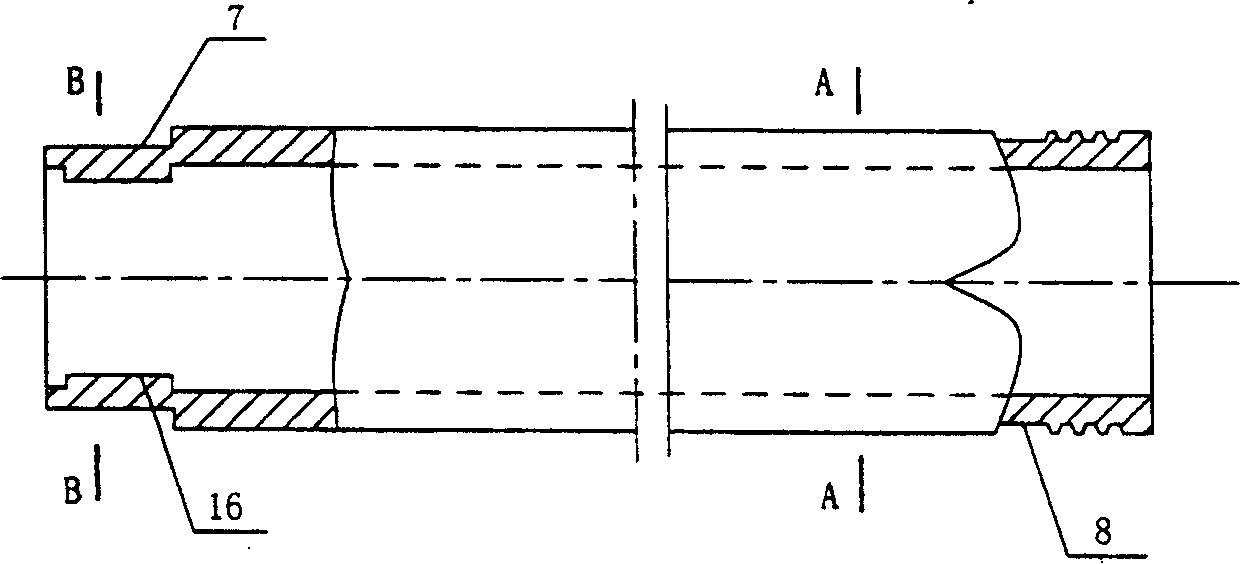

[0033] refer to figure 1 , a screw drive lifting rod of the present invention, which includes: 1 screw 9, 1 chassis 10, 6 nuts 3, 5 screw sleeves 8, 6 positioning blocks 11 and 7 outer sleeves 4. The dimensions of each lead screw cover 8, positioning block 11 and outer casing 4 are different, but the structure is roughly the same; the leading screw 9 is vertically and rotatably seated on the chassis 10, and the positioning block 11 is fixed on the upper end of the outer casing 4, and an outer casing The tube 4 is fitted with another outer sleeve 4 with a gap, the lower end of the outer sleeve 4 is fixed with the lower end of the nut 3 and the lower end of the lead screw sleeve 8, and the nut 3 is threaded with the outer surface of the lead screw sleeve 8 or the lead screw 9 , a lead screw sleeve 8 is fitted together with another lead screw sleeve 8 or lead screw 9 with a gap, and the outer casing 4 is square.

[0034] Four hanging lugs 12 are housed on one of two adjacent pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com