Back light module

A technology of backlight module and light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problem of uneven light output of backlight module, and achieve the effect of reducing assembly volume, improving light output uniformity, and eliminating dark shadow areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

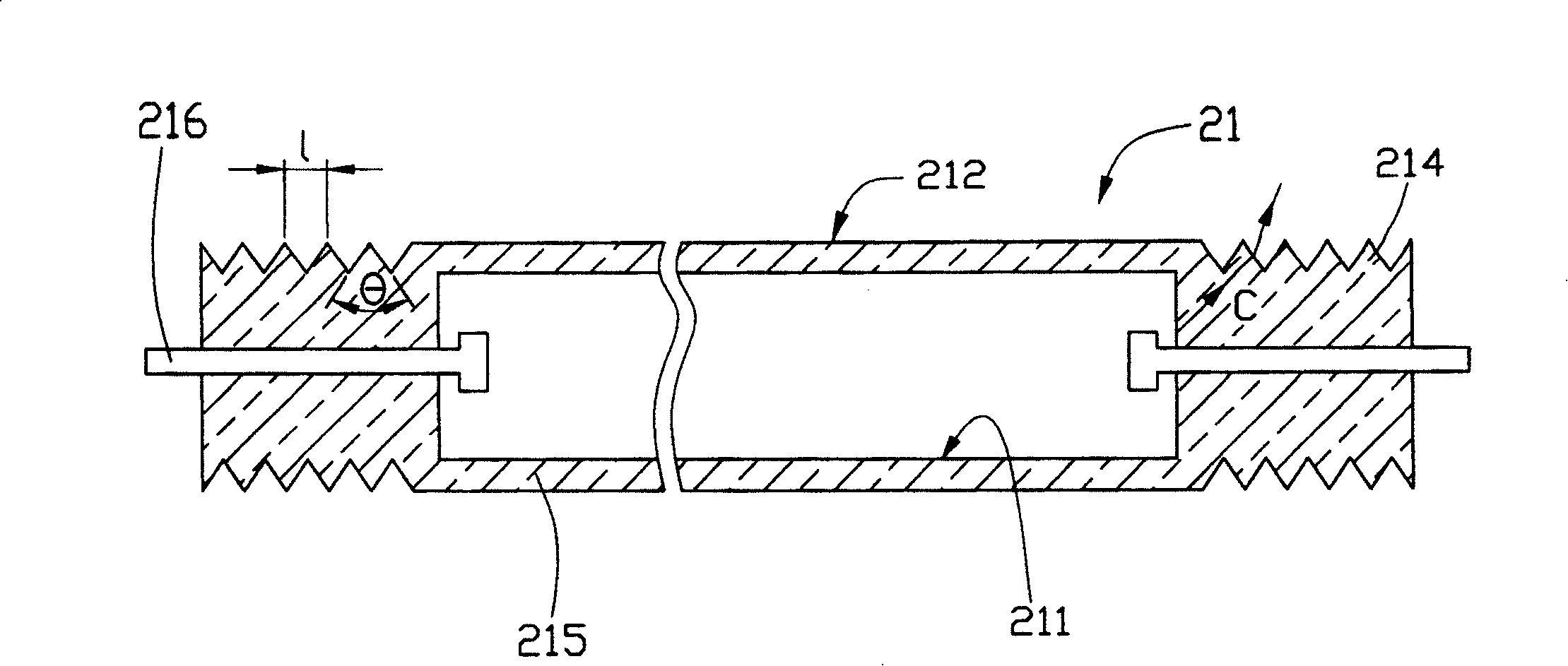

[0013] see image 3 , is a sectional view of the cold cathode fluorescent lamp 21 in the backlight module of the present invention, the cold cathode fluorescent lamp 21 is a closed glass tube 215, the inner side 211 of the tube wall is coated with phosphor (not shown), and the closed glass tube 215 is filled with mercury vapor ( Not shown), wherein the two ends of the closed glass tube 215 are engraved with a plurality of V-shaped grooves 214. The plurality of V-shaped grooves 214 are evenly distributed, and are manufactured by precision machining or photolithography. The pitch L of the V-shaped grooves 214 remains unchanged, the size is 10 μm˜20 μm, and the apex angle θ is 75°˜115°. During operation, a high voltage is applied to the electrodes 216 at both ends to ionize the mercury to emit ultraviolet light, and the ultraviolet light excites the fluorescent material 211 on the inner side of the tube wall to emit visible light. The light c is emitted from the inner side 211 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com