Multifunctional reactor for preparing ionic liquid

A reactor and reaction technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of no ionic liquid synthesis and preparation, and achieve saving Equipment investment and operating costs, cost reduction, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

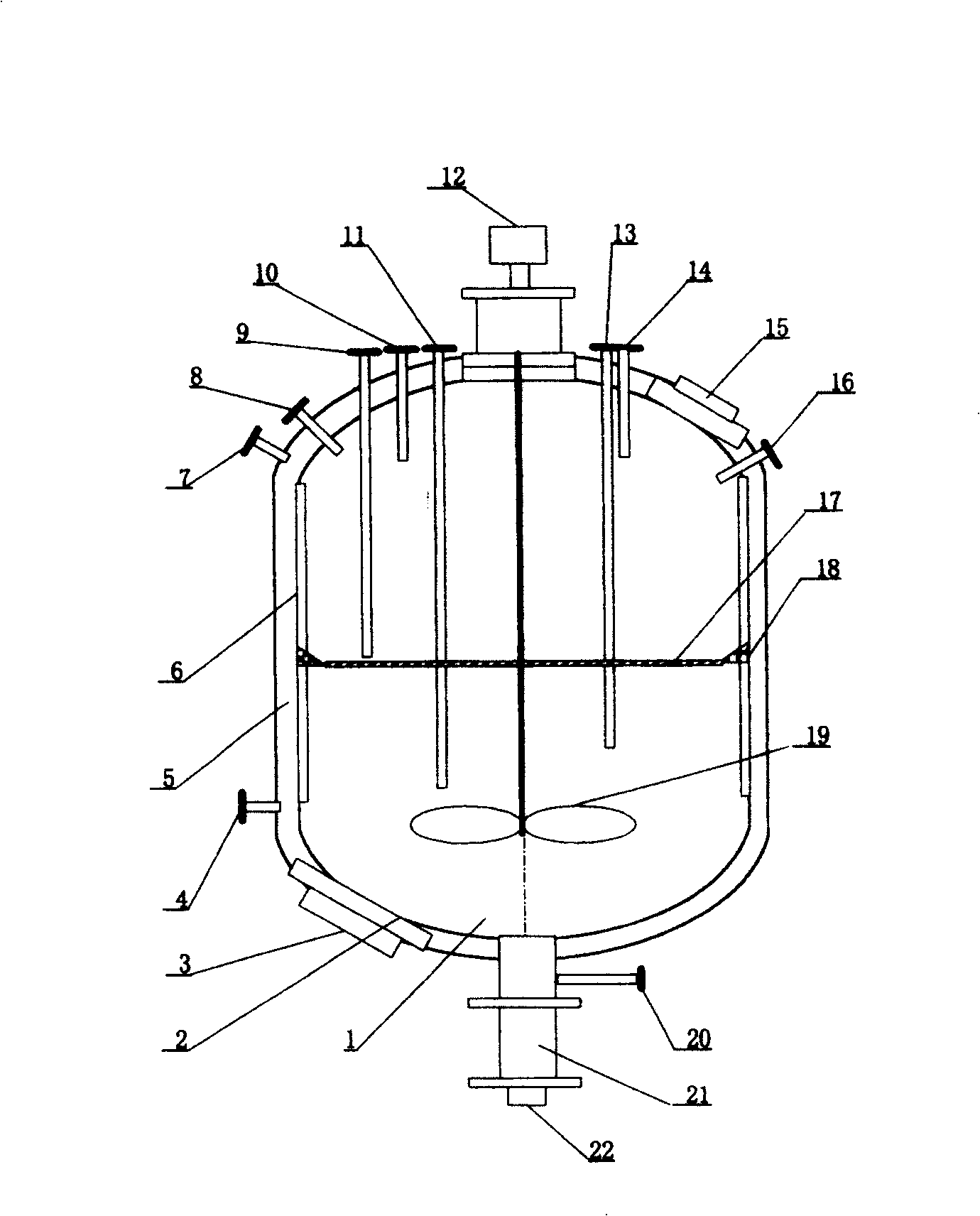

[0029] See figure 1 . One-pot reactor, the tank body is a jacketed tank body, the cavity of the tank body is the reaction chamber 1, and the hollow interlayer formed by the double-layer tank body wall is the jacket 5; a jacket medium is opened on the jacket 5 Inlet 7, a jacket medium outlet 4 is opened at the lower part of the jacket, a liquid feed port 10 is opened at the upper part of the tank body, and a vacuum tube 8 and a vacuum filter tube 9 are installed, and the air inlet of the vacuum filter tube is in the filter screen Above, the gas feed pipe 11, and the air outlet of the gas feed pipe is in the material below the filter screen, temperature sensor 13, pressure sensor 14, sight glass 15, condensate return pipe 16; The high-speed motor 12 is installed on the top of the tank body, and the stirring paddle is below the filter screen; a manhole or a hand hole 2 and a solid material outlet 3 are opened at the bottom of the tank body; a sampling port 20 is opened at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com