Synchronous circulation type spiral sealing belt device for electrostatic spinning

A technology of electrospinning and spiral sealing, which is applied in the direction of filament/thread forming, textile and paper making, fiber treatment, etc., to achieve the effect of long-term stability and long-term continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

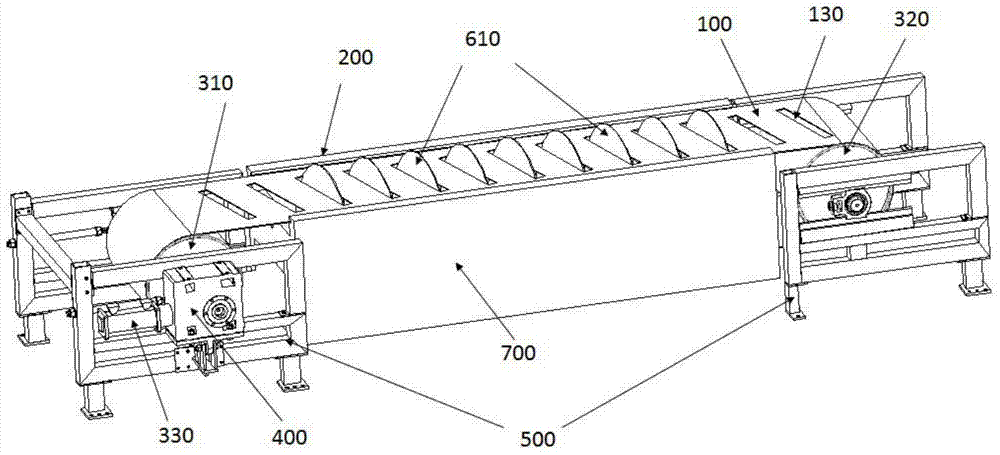

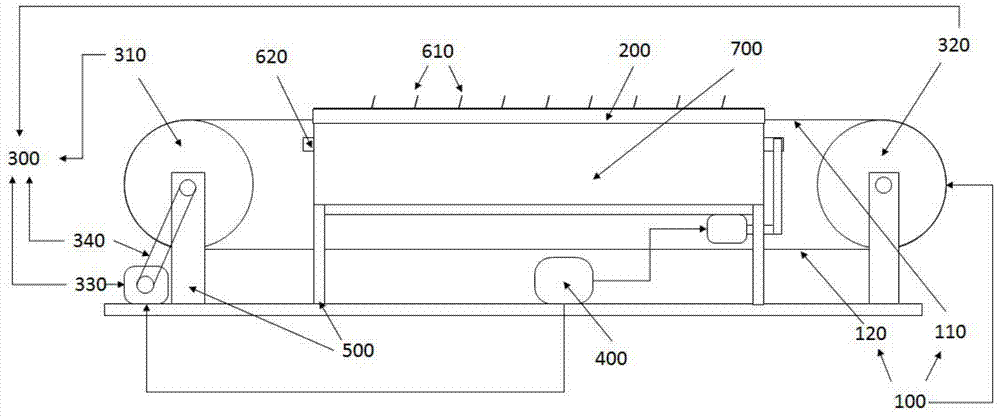

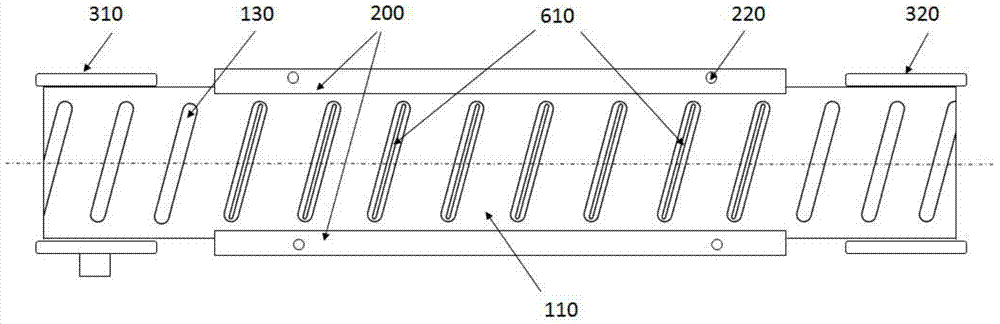

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] The following examples adopt the spinning equipment as a spiral electrospinning equipment, the spinning feed liquid is PVDF of 12% w / v, the molecular weight of PVdF is 500,000, and the viscosity range of the spinning feed liquid is 1100 ± 50cP; The solution is prepared by adding PVDF powder into a mixed solvent of acetone and DMF, keeping the temperature at 25°C, and fully stirring for 12 hours;

[0037] The relevant dimensions of the selected feed liquid tank 700 and the spiral electrode 600 are as follows:

[0038] (1) the length L1=500mm of the spiral electrode 600; (2) the pitch P=100mm of the spiral electrode; (3) the spiral blade diameter of the spiral electrode (4) The spiral blade thickness D1=3mm of the spiral electrode; (5) The rotating speed W of the spiral electrode 1 =6 (rev / min); the length L2=600mm of the feed liquid tank 700; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com