Ring spray electrostatic spinning machine and its application

An electrospinning and ring jet technology, applied in yarn, textile and papermaking, filament/thread forming, etc., can solve the problems of difficult real-time adjustment, incompetence for diversified production, inconvenient replacement of machine heads, etc. Mass production, ensure normal spinning, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

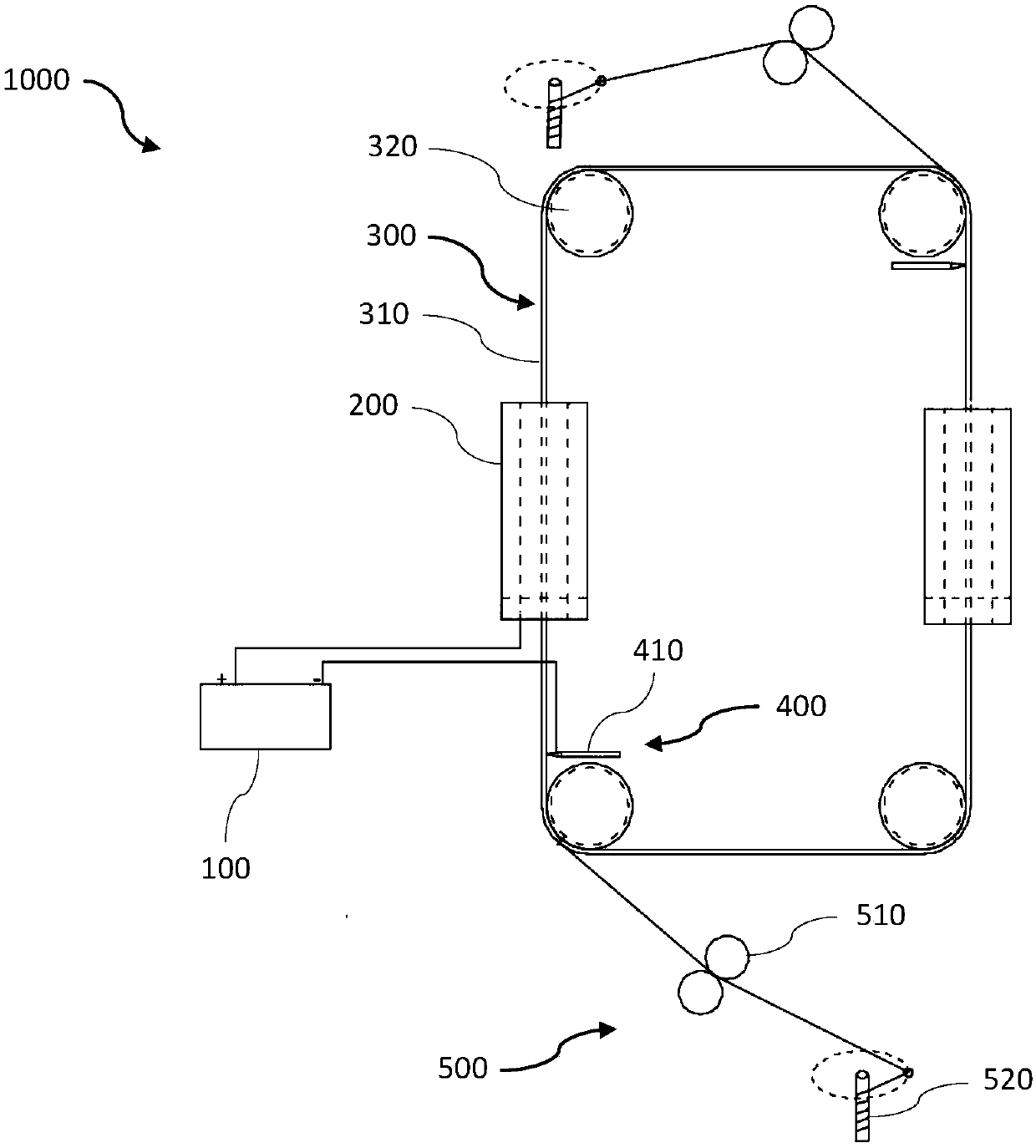

[0031] figure 1 It is a schematic structural diagram of a ring jet electrostatic spinning machine in an embodiment of the present invention.

[0032] Such as figure 1 As shown, a ring jet electrostatic spinning machine 1000 includes a high-voltage direct current power supply 100, m spinning devices 200, a spinning receiver 300, a stripping device 400, and a traction and twisting device 500. Among them, m is a natural number greater than or equal to 1, and two spinnerets 200 are used in this embodiment.

[0033] The high-voltage direct current power supply 100 is a high-voltage electrostatic generator with a positive electrode and a negative electrode for generating a high-voltage electrostatic field.

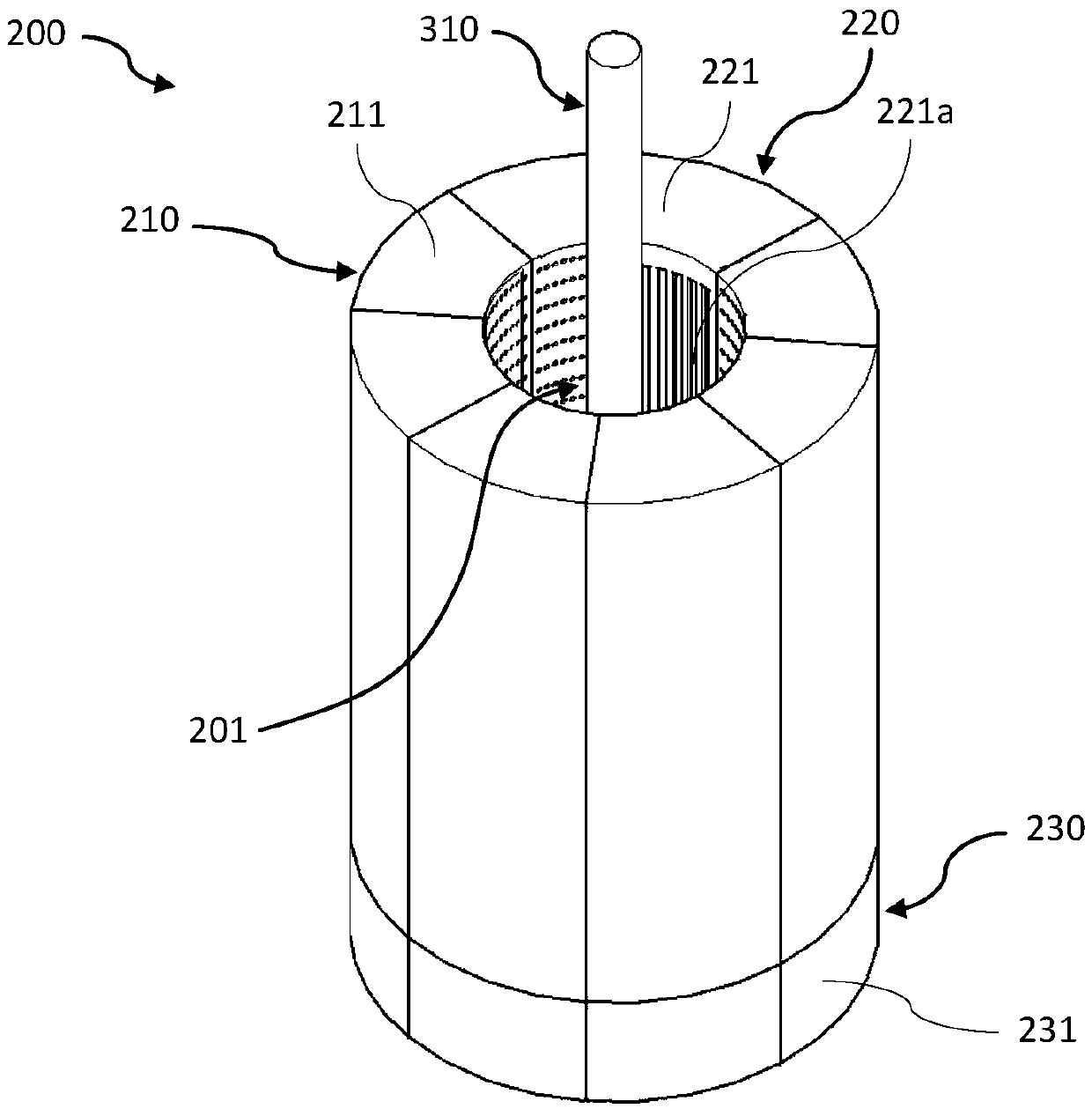

[0034] figure 2 It is a schematic diagram of the three-dimensional structure of the spinning device in the embodiment of the present invention;

[0035] Such as figure 2 As shown, the spinning device 200 is used to spin the spinning solution into fibers, and includes a fixed support (...

Embodiment 2

[0062] The second embodiment is a further improvement of the first embodiment. For the same structure as in the first embodiment, the same symbols are given, and the same description is omitted.

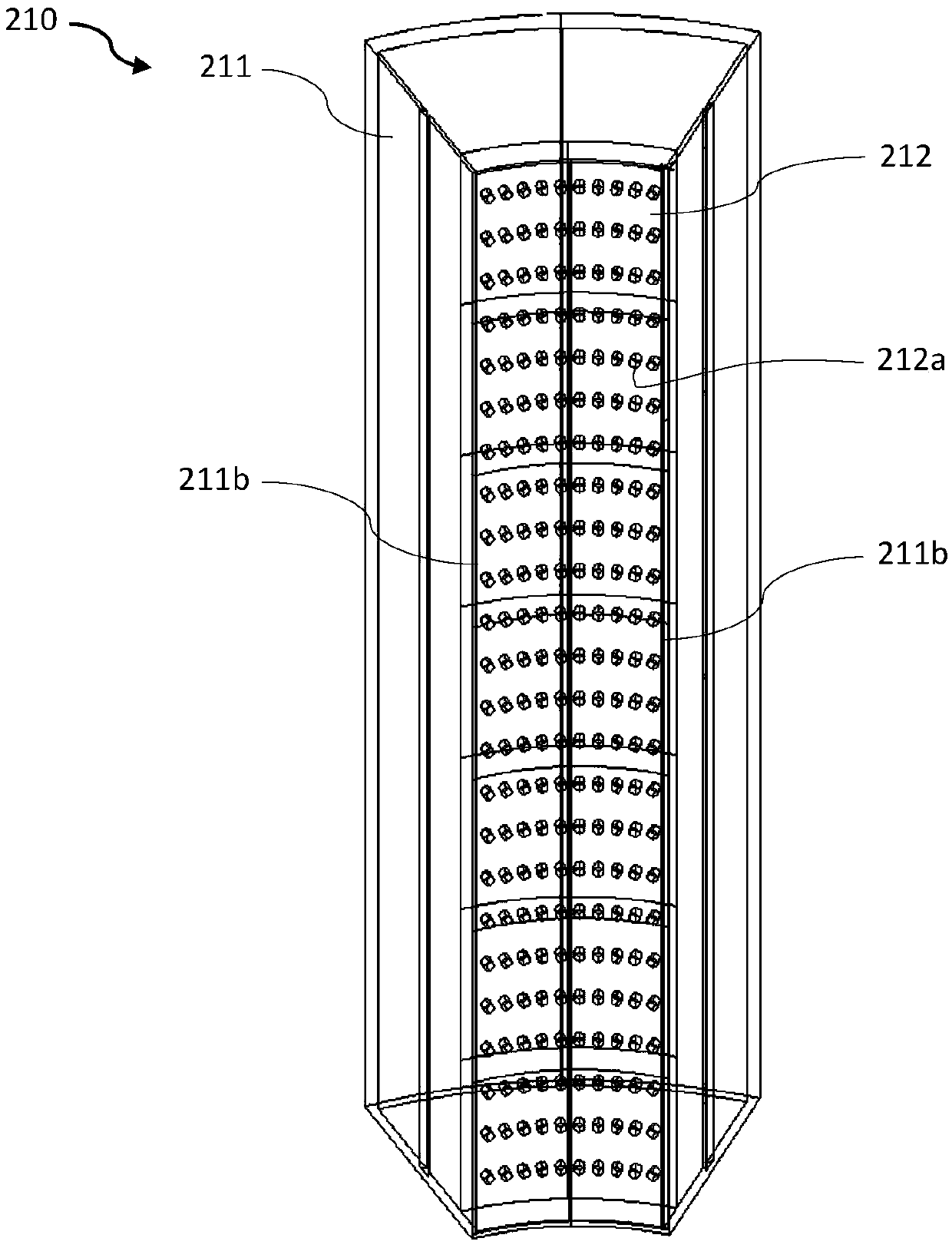

[0063] Such as image 3 As shown, the spinneret 212 moves up and down along the spinneret 211 to make the spinneret hole 212a and the liquid outlet hole 211a relatively close or stagger. The specific structure is: both the left and right sides of the spinneret 212 are provided There is a buckle (not shown in the figure), the spinneret 211 is provided with a vertical groove 211b matching the buckle on the side close to the hollow cavity 201, and the spinneret 212 is movably inserted into the corresponding The spinneret 212 is installed on the spinneret 211 in the vertical slot 211b, and the spinneret 212 moves up and down along the spinneret 211.

[0064] The end of each spinneret 211 is correspondingly provided with a spinneret driving part for driving the spinneret 212 to move up and dow...

Embodiment 3

[0067] The third embodiment is a further improvement of the first and second embodiments. For the same structures as those in the first and second embodiments, the same symbols are given, and the same descriptions are omitted.

[0068] In this embodiment, the liquid injection unit in the first embodiment is omitted, and the spinneret 211 adopts a cartridge-type structure that is repeatedly filled with liquid and has its own pressurizing unit. The specific structure is as follows:

[0069] Such as Figure 4 As shown, a vertical partition 214c is provided in the spinneret 211 to divide the inner space of the spinneret 211 into a spinneret chamber 211d and a pressurized chamber 211e. The spinning chamber 211d is close to the hollow cavity 201, and the outlet hole 211a is connected to the spinning chamber 211d; the pressurizing chamber 211e is away from the hollow cavity 201, and the spinning chamber 211d and the pressurizing chamber 211e are in the vertical partition 211c Connected at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com