Magnesia crucible for synthesizing sodium-sulfur cell solid electrolyte and preparation method of magnesia crucible

A technology of solid electrolyte and sodium-sulfur battery, which is applied in the field of magnesia crucible for synthesizing solid electrolyte of sodium-sulfur battery and its preparation, which can solve the problem of affecting the comprehensive performance of electrolyte ceramic tube and battery, increasing the production cost of electrolyte ceramic tube, and unfavorable industrialization process, etc. problems, achieve the effects of eliminating the possibility of defects and impurity contamination, inhibiting the rapid volatilization of sodium components, and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

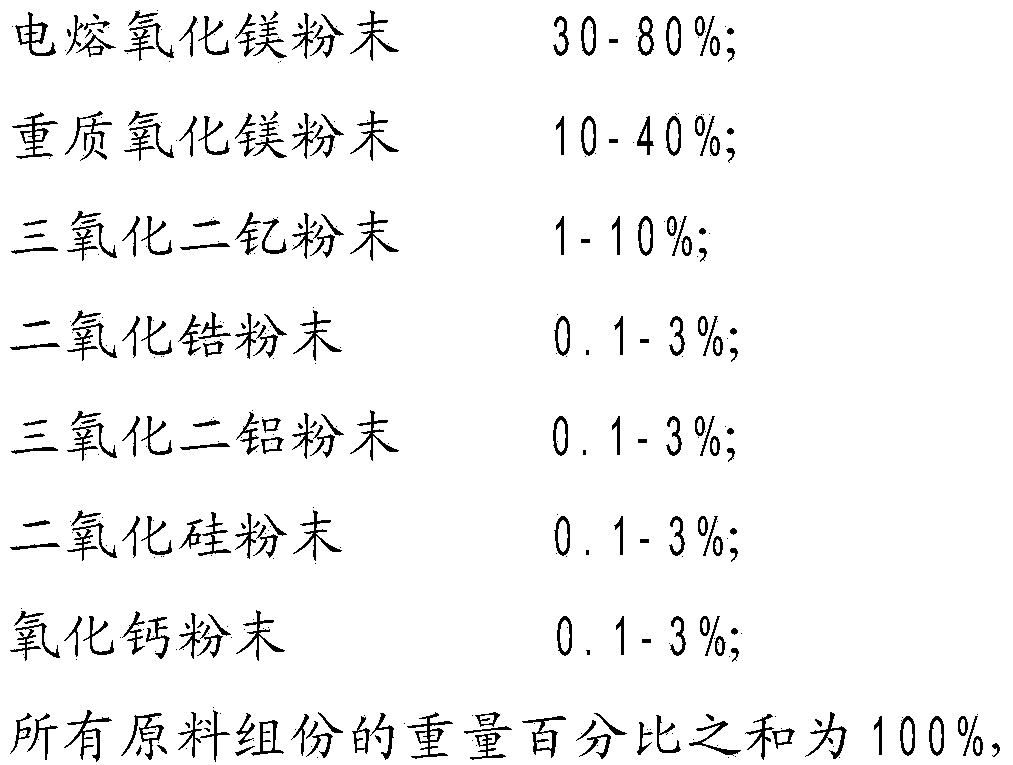

[0026] 65 parts by weight of fused magnesia powder, 26 parts by weight of heavy magnesia powder, 5 parts by weight of yttrium oxide powder, 1 part by weight of zirconia powder, 1 part by weight of aluminum oxide powder, 1 part by weight of silicon dioxide powder and 1 part by weight of calcium oxide powder were put into the mixer and mixed for 4 hours, wherein the particle range of fused magnesia powder was 60-75 μm, that of heavy magnesia powder was 5-7 μm, and the rest of the raw materials were The parts are all less than 5 μm, and the purity of all raw material components is greater than 99%.

[0027] After mixing evenly, pour it into the isostatic pressing molding rubber sleeve mold, hold the pressure for 20s under the action of 200MPa, and take it out under the pressure reduction to obtain the green body of the magnesia crucible.

[0028] Put the green magnesia crucible into a clean high-temperature gas-fired furnace, burn it to 1780°C in an air atmosphere, keep it warm f...

Embodiment 2

[0031] 70 parts by weight of fused magnesia powder, 21 parts by weight of heavy magnesia powder, 4 parts by weight of yttrium oxide powder, 1 part by weight of zirconia powder, 2 parts by weight of aluminum oxide powder, 1 part by weight of silicon dioxide powder and 1 part by weight of calcium oxide powder were put into the mixer and mixed for 4 hours, wherein the particle range of fused magnesia powder was 60-75 μm, that of heavy magnesia powder was 5-7 μm, and the rest of the raw materials were The parts are all less than 5 μm, and the purity of all raw material components is greater than 99%.

[0032] After mixing evenly, pour it into the isostatic pressing molding rubber sleeve mold, hold the pressure for 20s under the action of 190MPa, and take it out under the pressure reduction to obtain the green body of the magnesia crucible.

[0033] Put the green magnesia crucible into a clean high-temperature gas-fired furnace, burn it to 1830°C in an air atmosphere, keep it warm ...

Embodiment 3

[0036] 68 parts by weight of fused magnesia powder, 24 parts by weight of heavy magnesia powder, 4 parts by weight of yttrium oxide powder, 1 part by weight of zirconia powder, 1 part by weight of aluminum oxide powder, 1 part by weight of silicon dioxide powder and 1 part by weight of calcium oxide powder were put into the mixer and mixed for 4 hours, in which the particle range of fused magnesia powder was 60-75 μm, that of heavy magnesia powder was 5-7 μm, and the rest of the raw materials were The parts are all less than 5 μm, and the purity of all raw material components is greater than 99%.

[0037] After mixing evenly, pour it into the isostatic pressing molding rubber sleeve mold, hold the pressure for 20s under the action of 180MPa, and take it out under the pressure reduction to obtain the green body of the magnesia crucible.

[0038] Put the green magnesia crucible into a clean high-temperature gas-fired furnace, burn it to 1800°C in an air atmosphere, keep it warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com