A kind of nano-silver wire-silver complex composite conductive ink and preparation method of transparent conductive film thereof

A technology of transparent conductive film and nano-silver wire, which is applied in the field of liquid crystals, can solve the problems of inability to improve the stability of nano-silver wire ink, short shelf life, agglomeration and sedimentation, etc., and achieve the goal of being suitable for large-area continuous industrial production, improving conductivity and The effect of uniformity and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

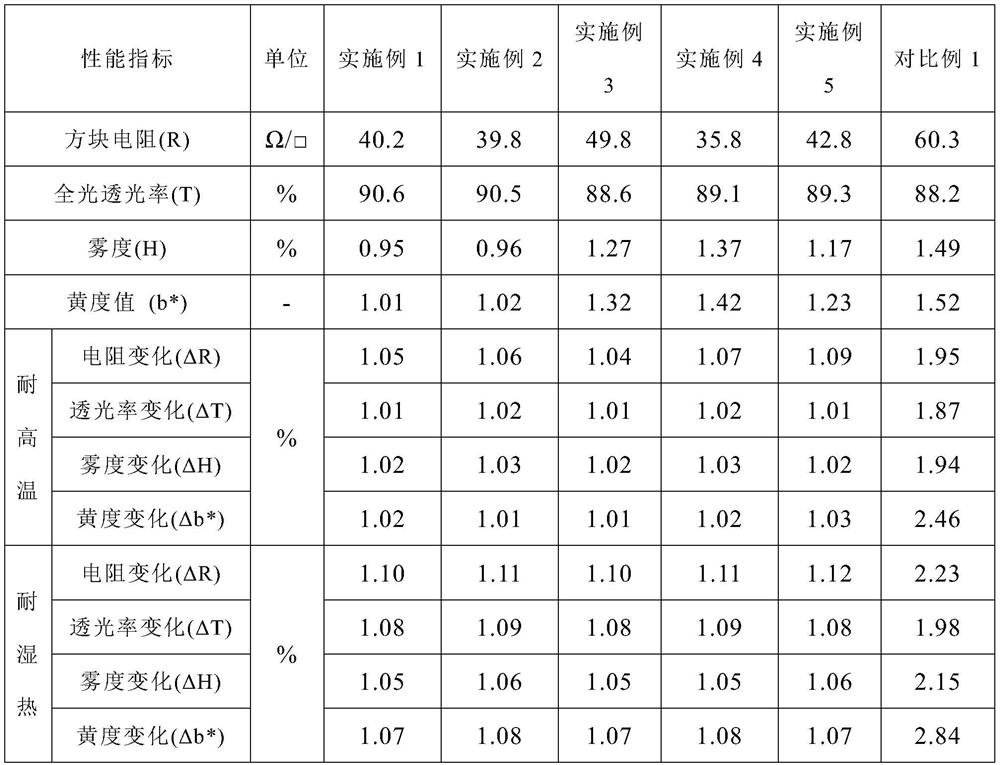

Examples

preparation example Construction

[0030] A preparation method of nano-silver wire transparent conductive film, the method comprising the following steps:

[0031] (1) Corona or plasma treatment is performed on the flexible transparent substrate;

[0032] (2) the nano-silver wire-silver complex composite conductive ink according to claim 1 is applied to the flexible transparent substrate surface by slit coating, slope coating, micro-gravure coating or doctor blade coating method, After thermal curing, a nano-silver wire-silver complex composite conductive layer is formed;

[0033] (3) Apply the protective layer coating solution to the surface of the nano-silver wire-silver complex composite conductive layer by slit coating, slope coating, micro-gravure coating or doctor blade coating method, and heat-cure or light-cure Finally, a protective layer is formed to obtain a transparent conductive film of nano-silver wires.

[0034]The flexible transparent substrate suitable for the present invention requires certai...

Embodiment 1

[0039] Step 1: Handling the Flexible Transparent Substrate

[0040] 100μm thick PET is selected, the width is 550mm, the total light transmittance is 91.3%, the haze is 0.34%, and the surface energy is 36dyn / cm after 0.8kV voltage corona.

[0041] The second step: preparation of nano-silver wire-silver complex composite layer

[0042] Preparation of nano-silver wire-silver complex composite conductive ink: 1) Disperse nano-silver wires with a wire diameter of 25nm and a length of 15 μm in ethanol solvent, and prepare 8L of nano-silver wire ink with a concentration of 0.5wt%; 2) Disperse the silver complex AgSCN in the stabilizer terpineol, and prepare 2L silver complex ink with a concentration of 10wt%; 3) then mix 8L nano-silver wire ink and 2L silver complex ink, and stir for 0.5h Form nano silver wire-silver complex conductive ink.

[0043] Coating nano-silver wire-silver complex conductive ink: use a slit coater to coat the above-prepared nano-silver wire-silver complex ...

Embodiment 2

[0048] Step 1: Handling the Flexible Transparent Substrate

[0049] Use PC with a thickness of 125 μm, a width of 560 mm, a total light transmittance of 88.2%, a haze of 0.78%, and a surface energy of 38 dyn / cm after corona with a voltage of 0.6 kV.

[0050] The second step: preparation of nano-silver wire-silver complex composite layer

[0051] Preparation of nano-silver wire-silver complex composite conductive ink: 1) Disperse nano-silver wires with a wire diameter of 50 nm and a length of 10 μm in an aqueous solvent to prepare 8.5 L of nano-silver wire ink with a concentration of 1 wt %; 2) Silver complex AgOCN is dispersed in stabilizer 2-phenoxyethanol, is mixed with the silver complex ink 1.5L of 8wt%; 3) then 8.5L nano-silver line ink and 1.5L silver complex ink are mixed , and stirred for 0.5h to form silver nano wire-silver complex conductive ink.

[0052] Coating nano-silver wire-silver complex conductive ink: use a slope flow coater to coat the above-prepared nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com