Patents

Literature

52results about How to "Improve resistance uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

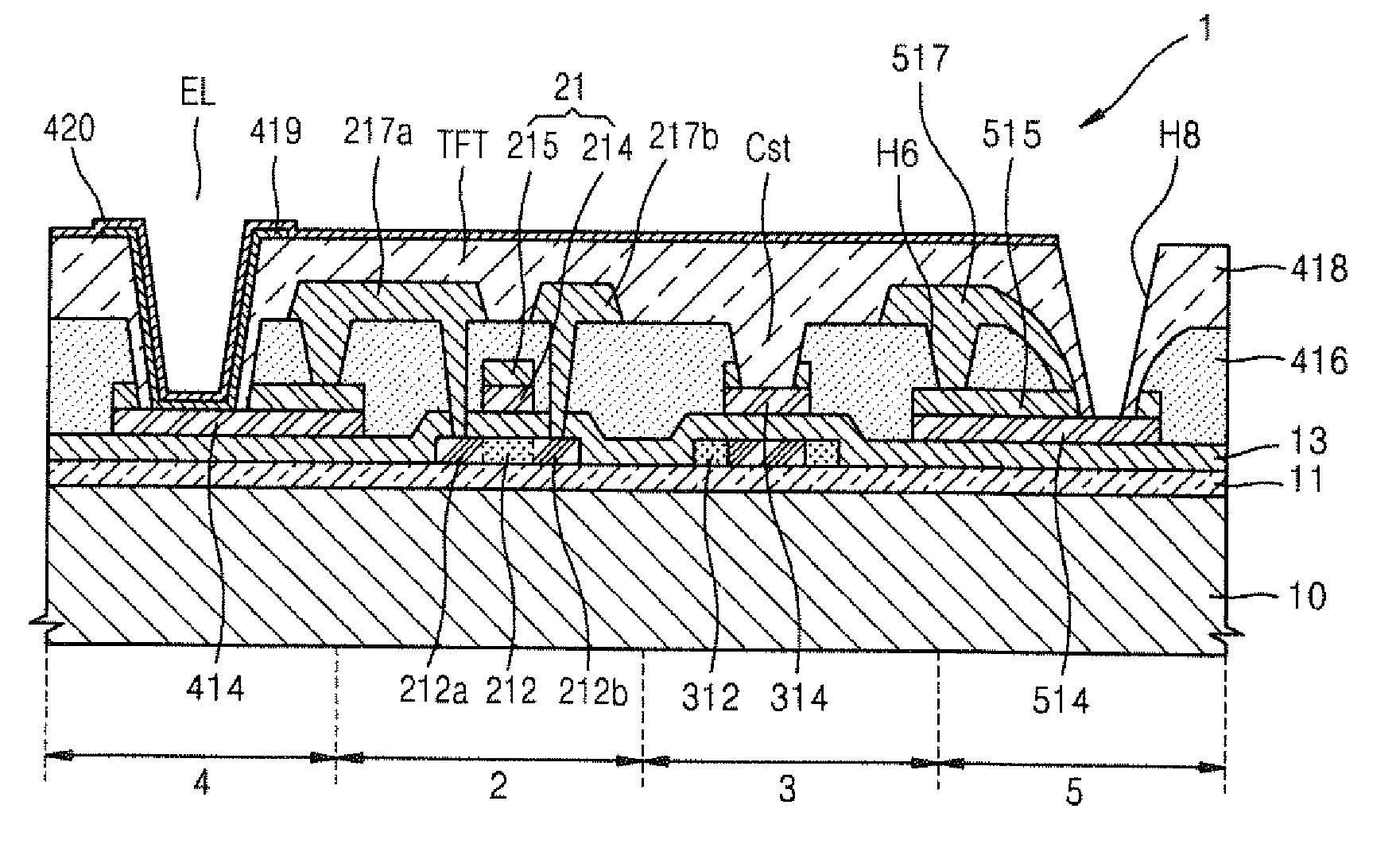

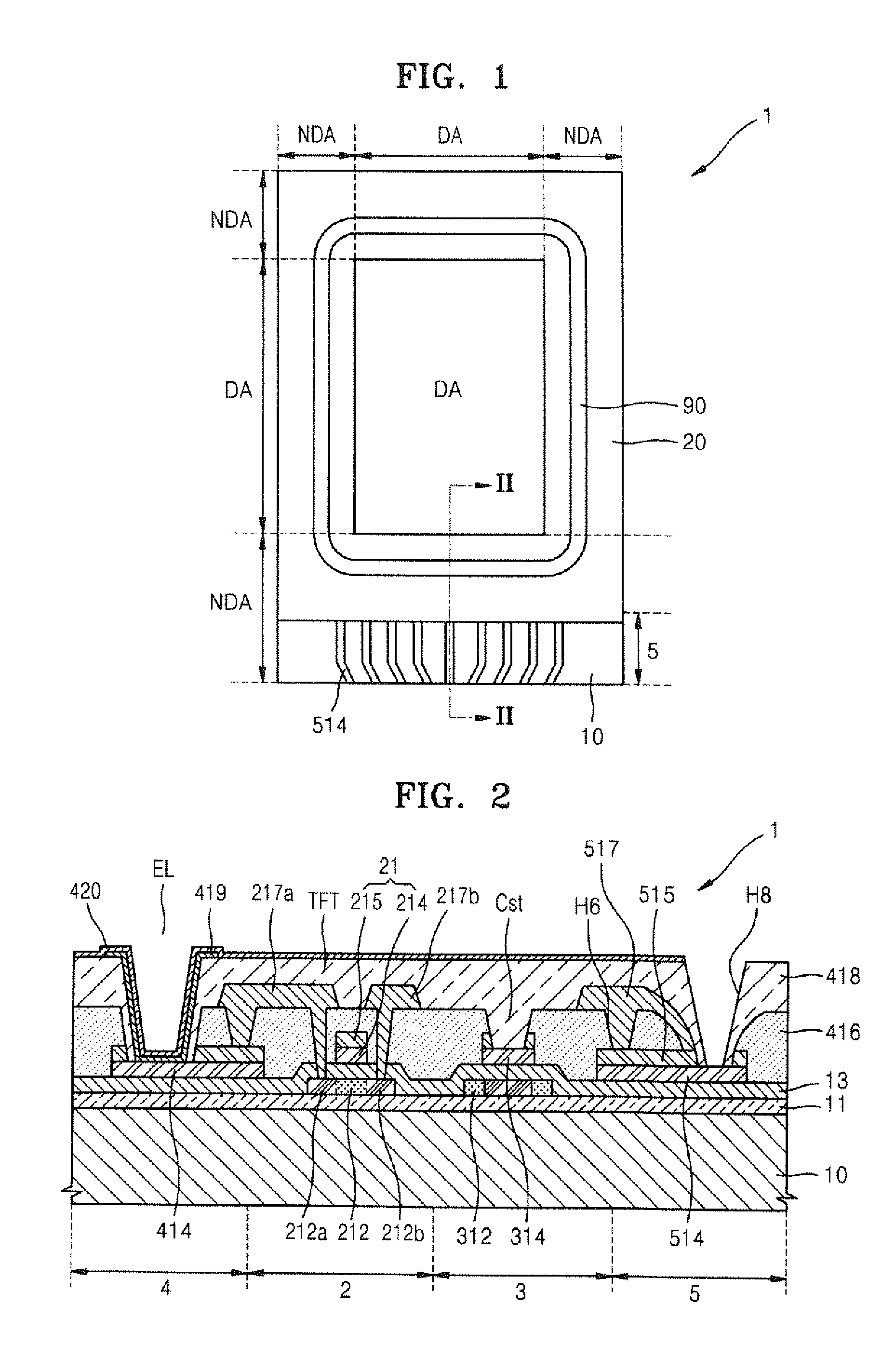

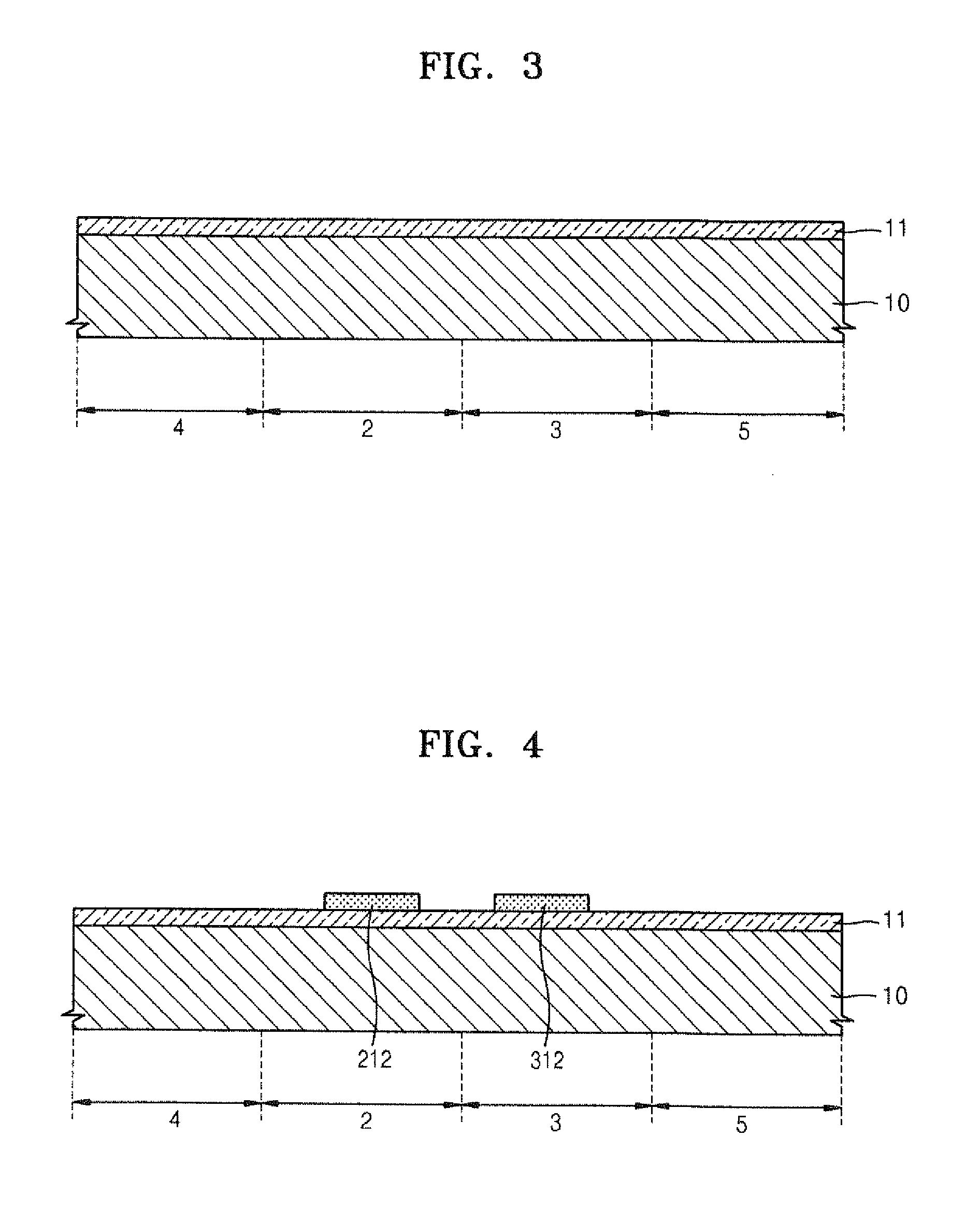

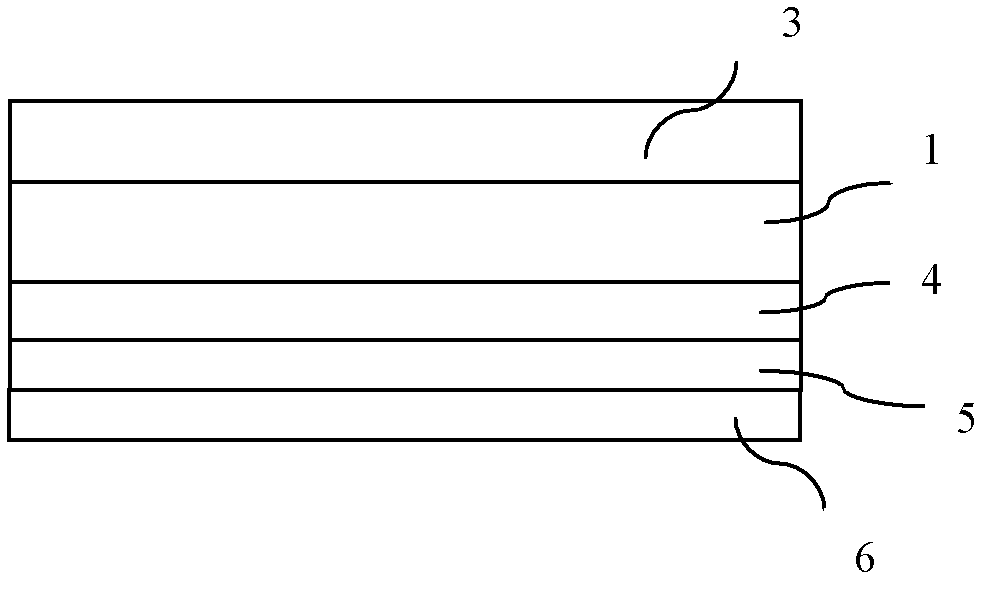

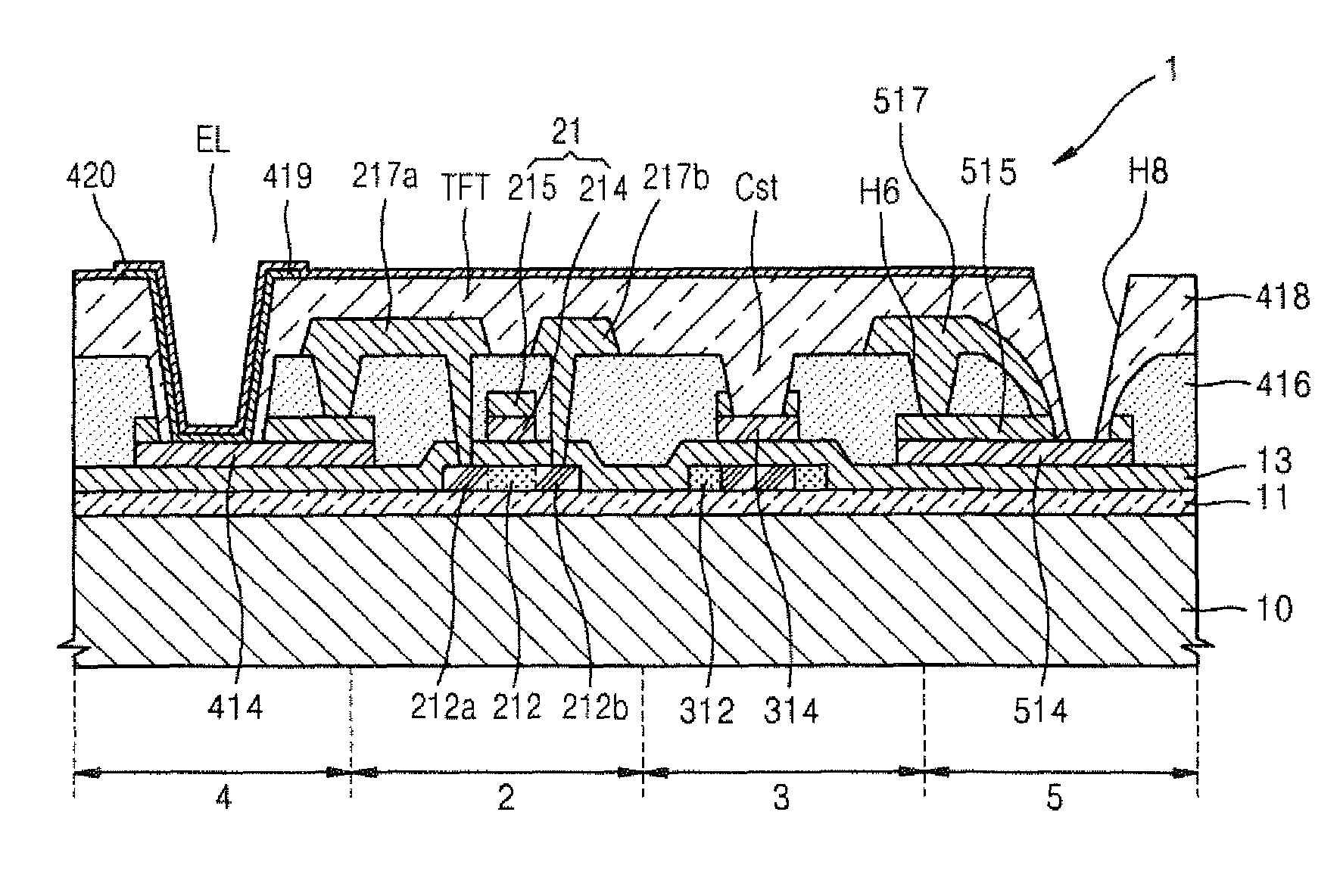

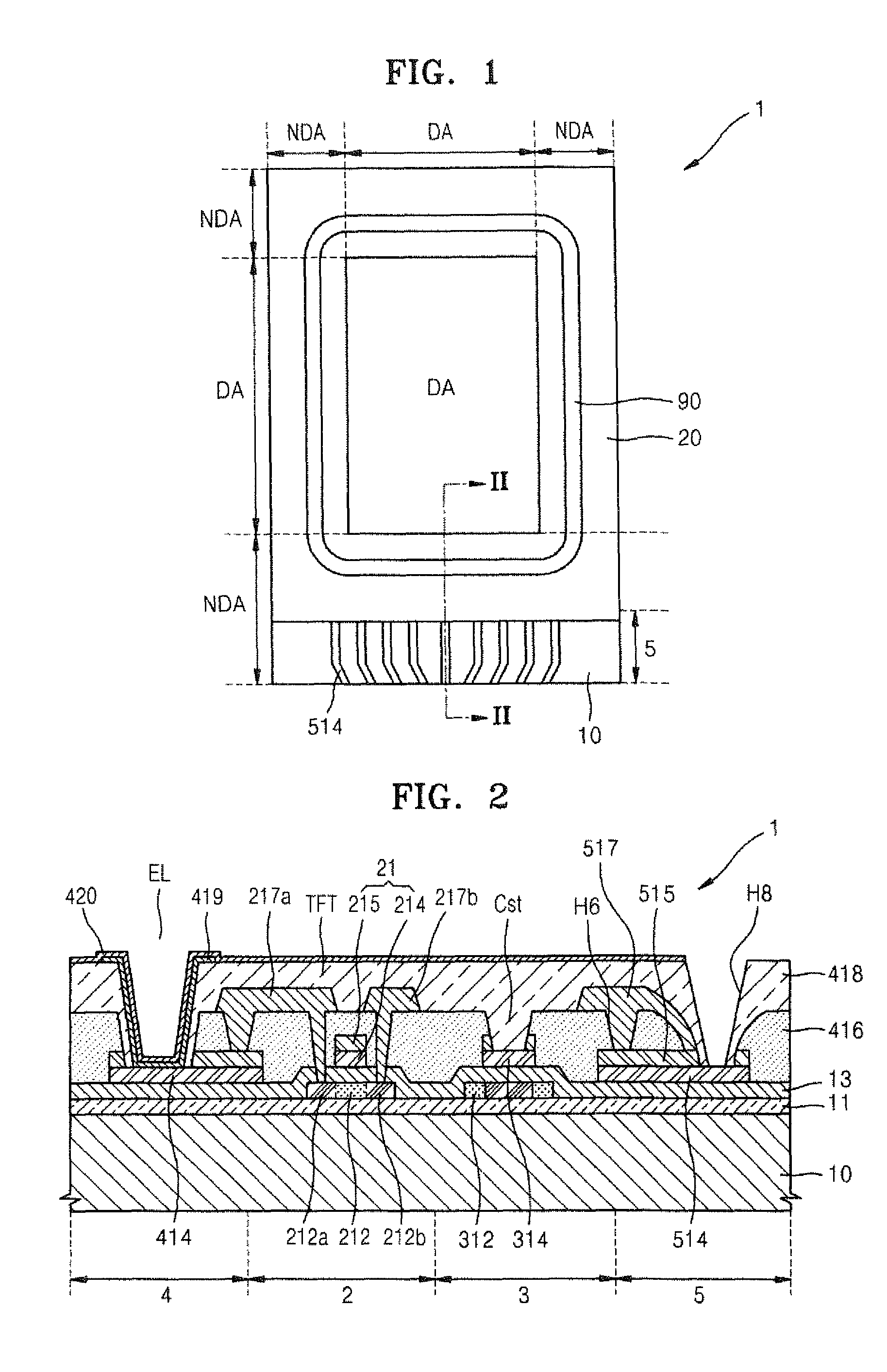

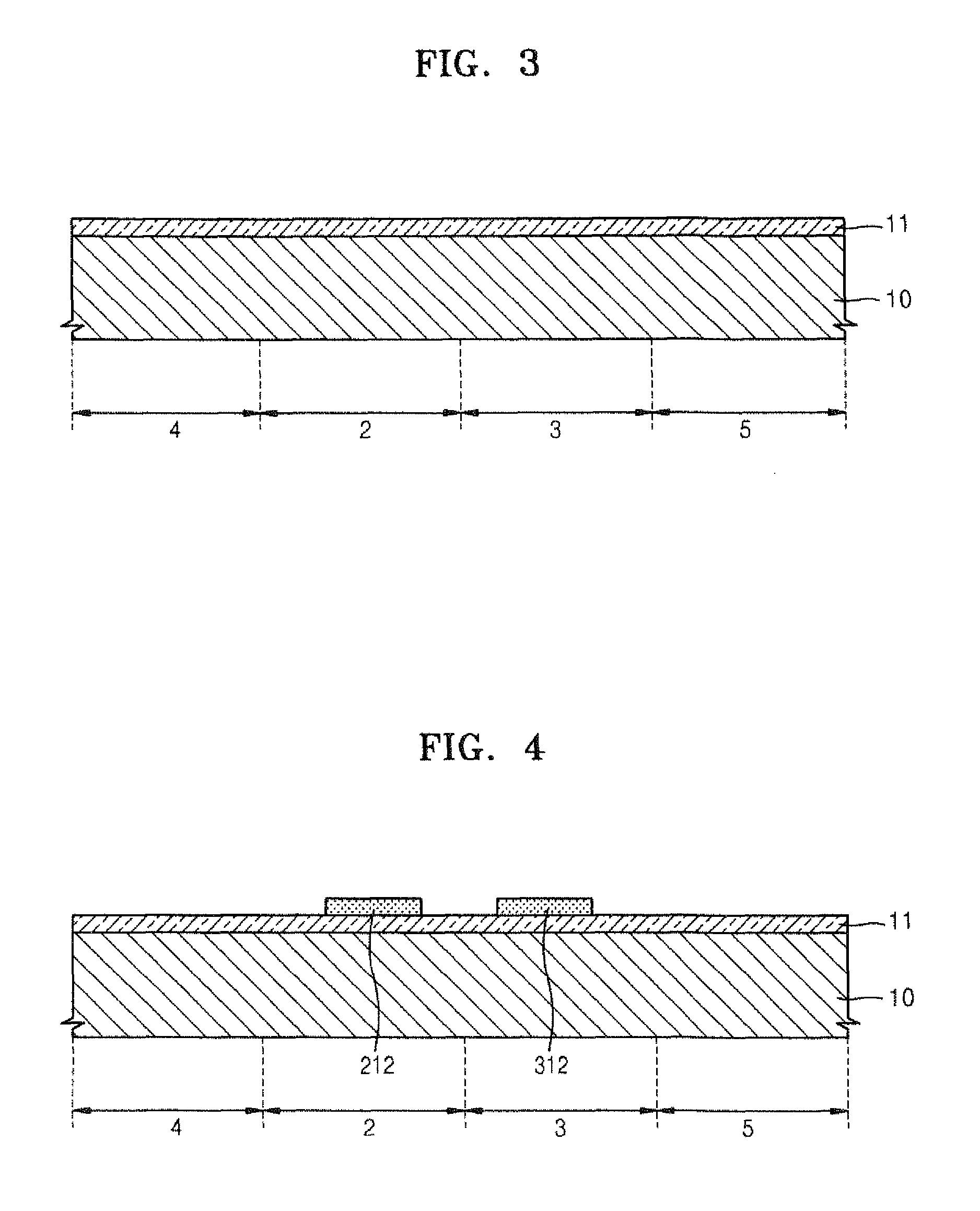

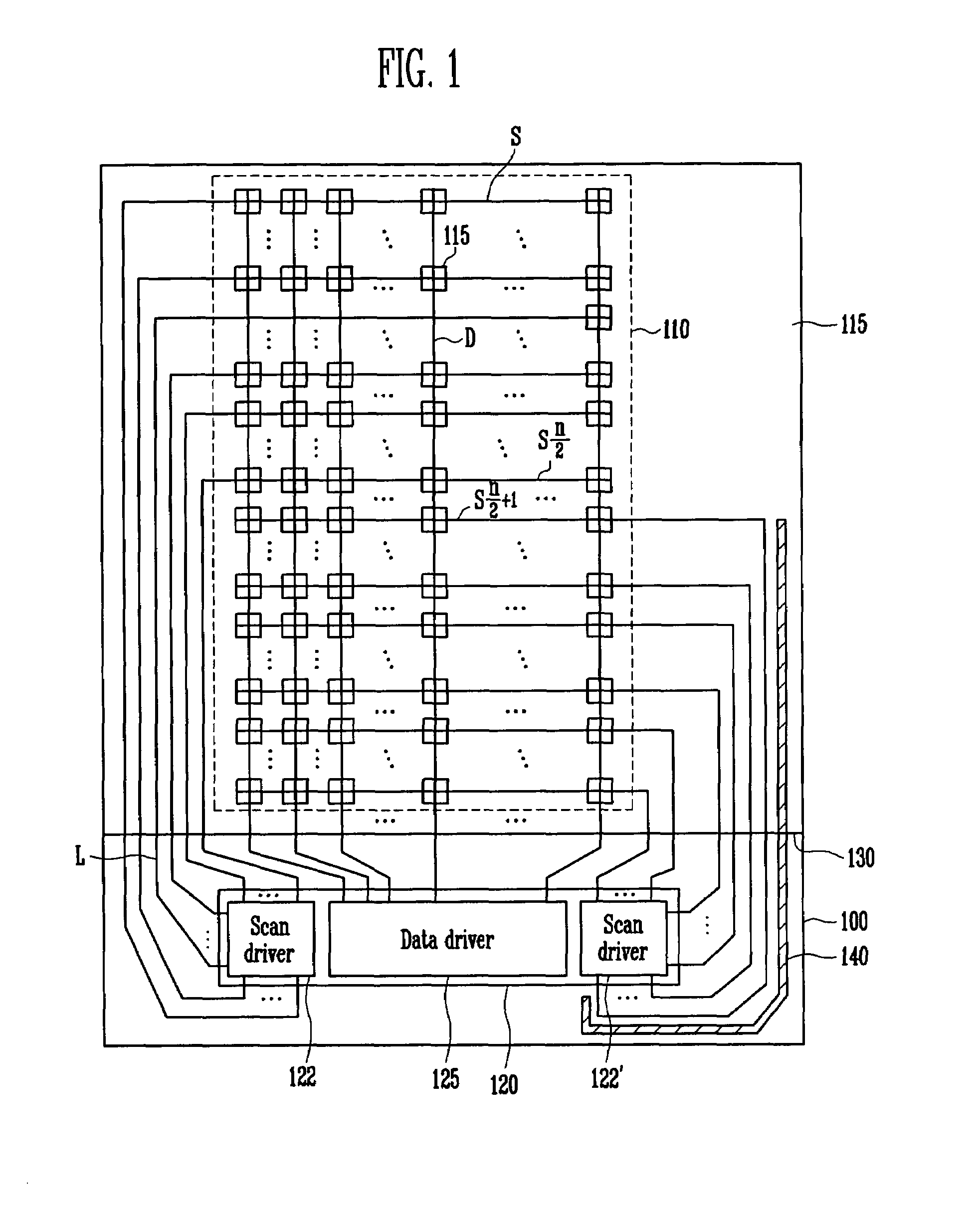

Organic Light Emitting Display Device and Manufacturing Method for the Same

ActiveUS20120146060A1Simple manufacturing processImprove resistance uniformitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceDisplay device

An organic light emitting display device may comprises a thin film transistor including an active layer, a gate electrode including a gate lower electrode and a gate upper electrode, a source electrode, a drain electrode, and an organic light emitting device electrically connected to the thin film transistor. A pixel electrode formed of the same material and in the same layer as the gate lower electrode, an intermediate layer including a light emitting layer, and an opposed electrode are sequentially deposited. A first pad electrode is formed in the same layer as the gate lower electrode, a second pad electrode is formed on at least a part of the first pad electrode and in the same layer as the gate upper electrode, and a third pad electrode contacts at least a part of the second pad electrode and is formed in the same layer as the source electrode.

Owner:SAMSUNG DISPLAY CO LTD

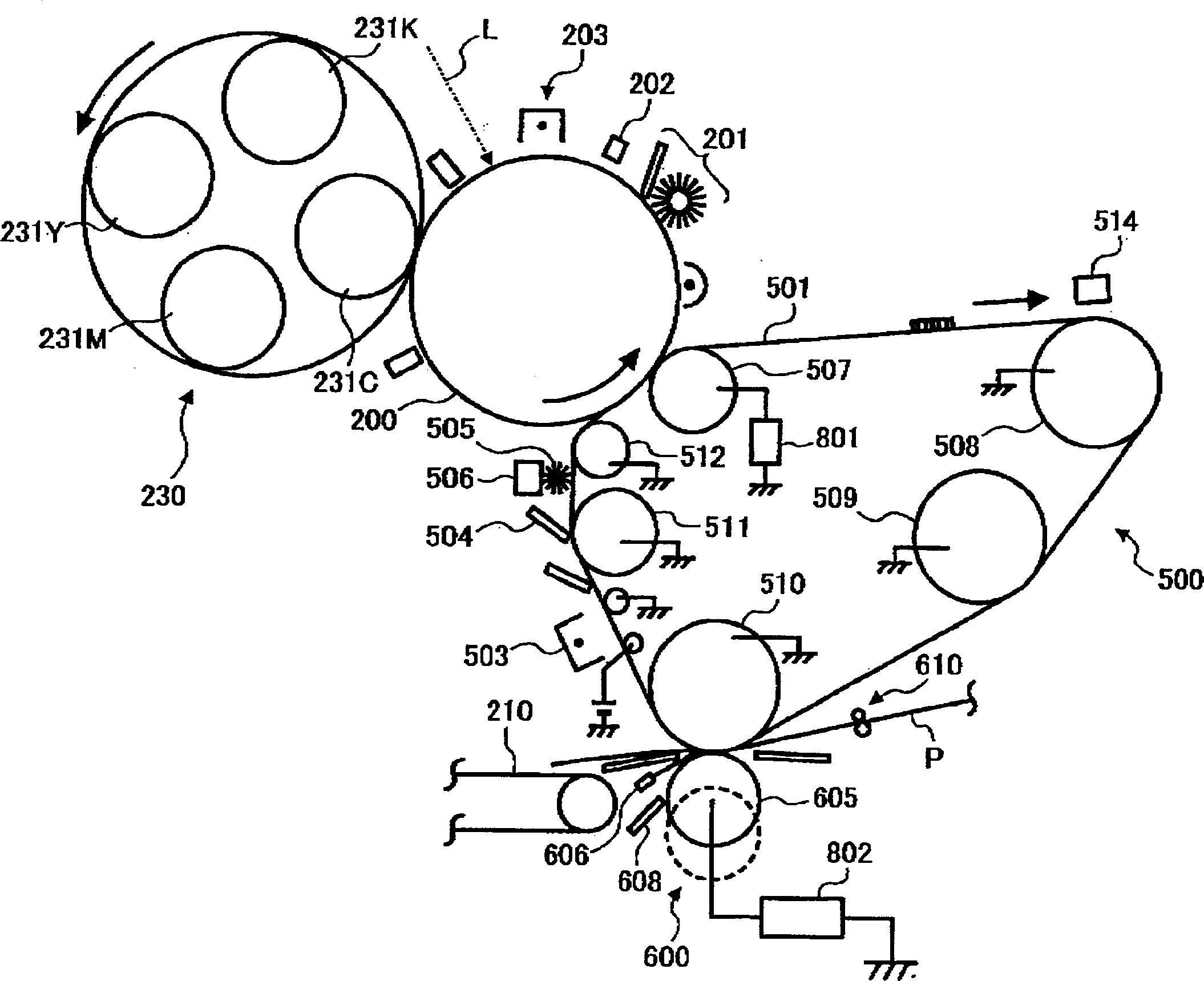

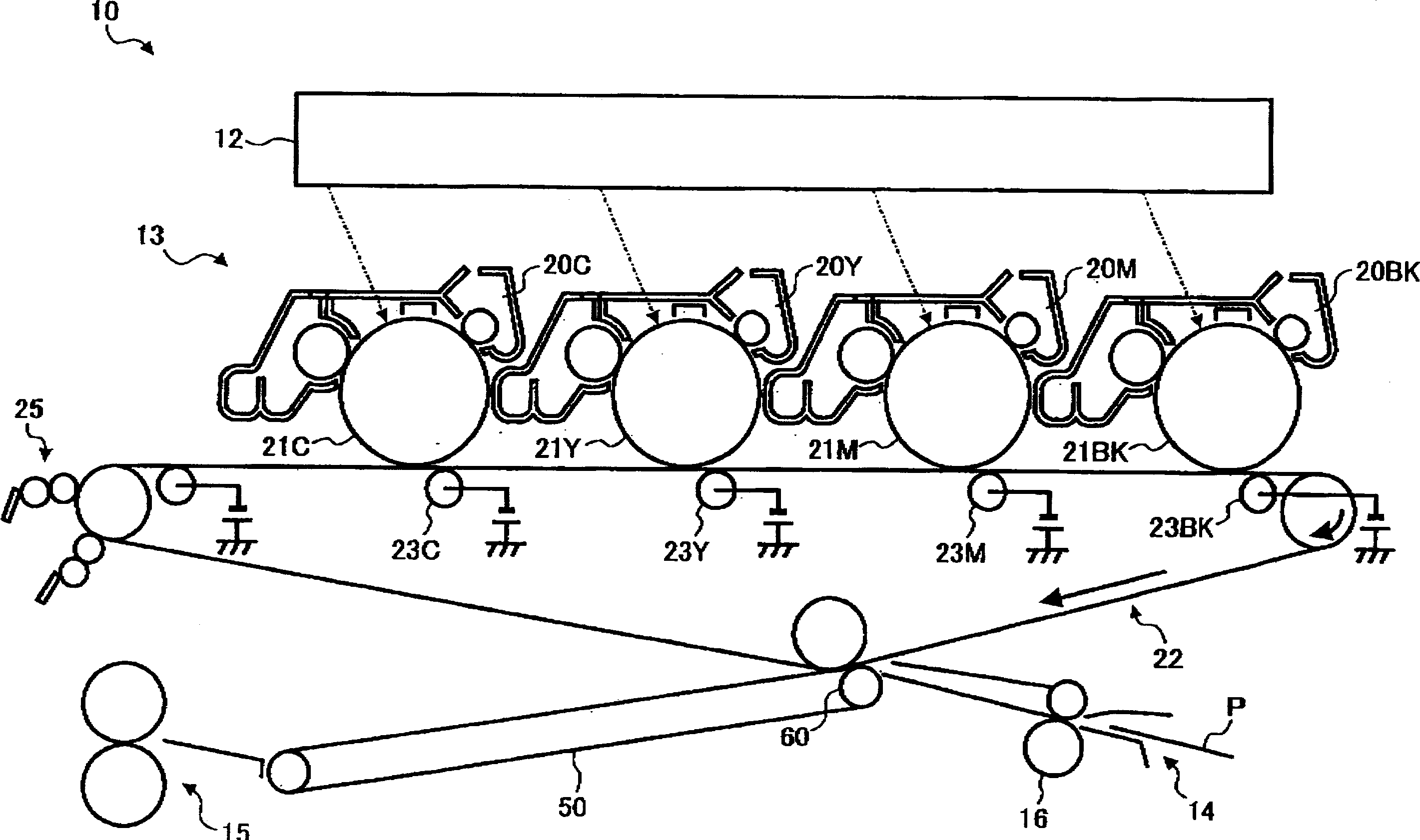

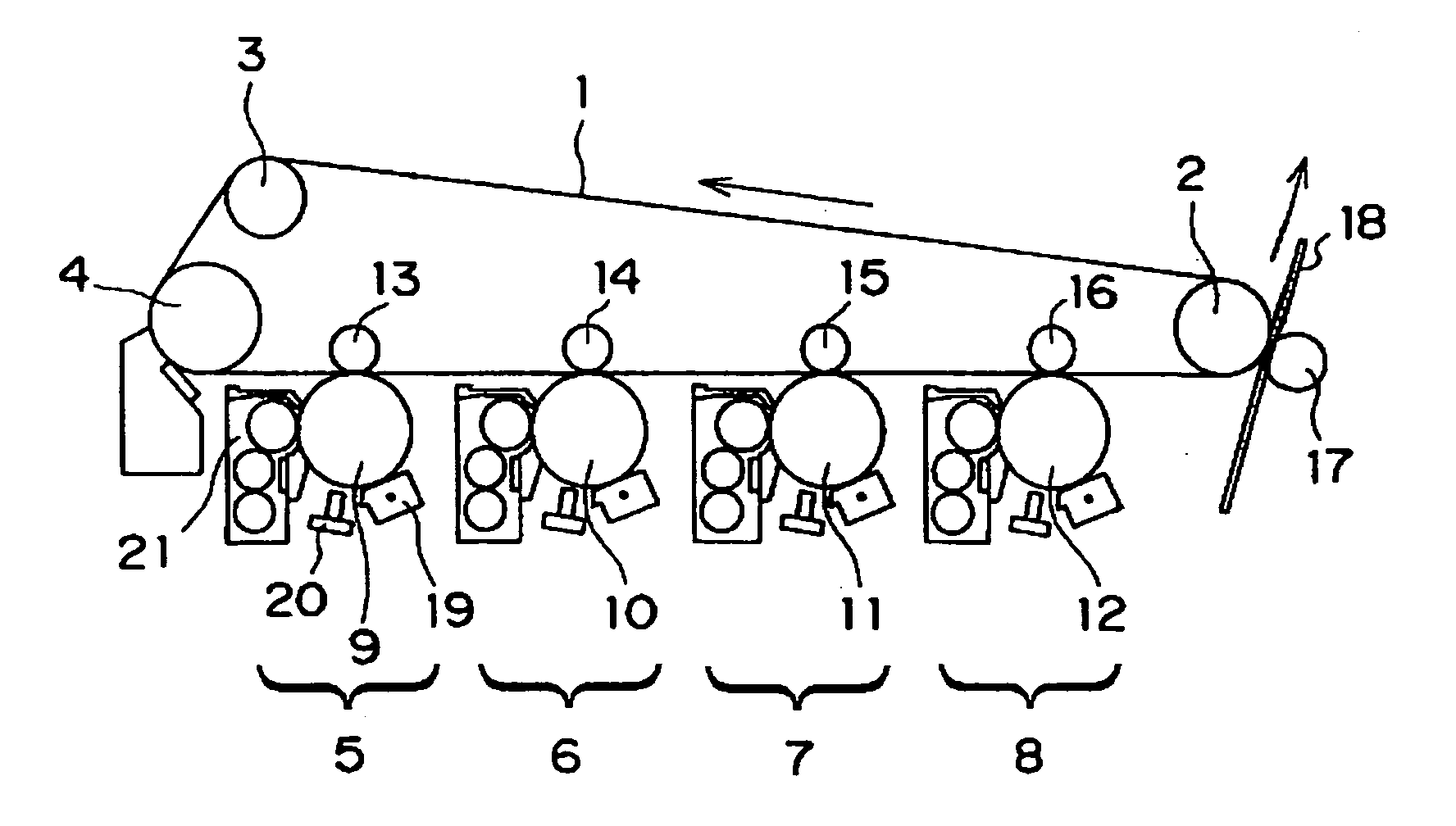

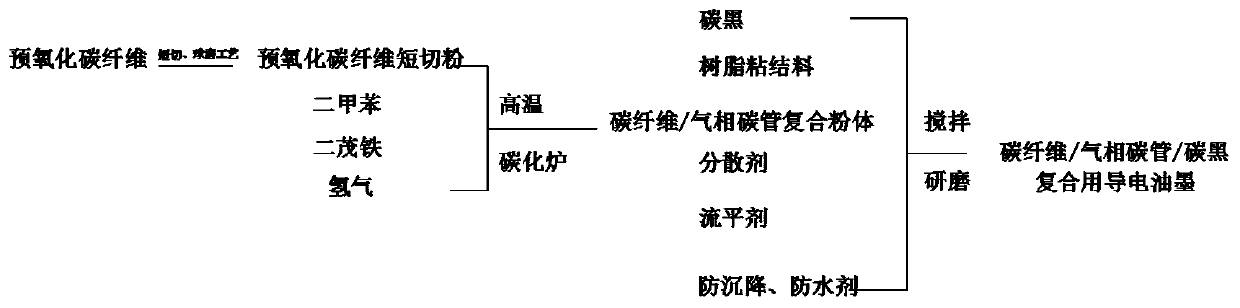

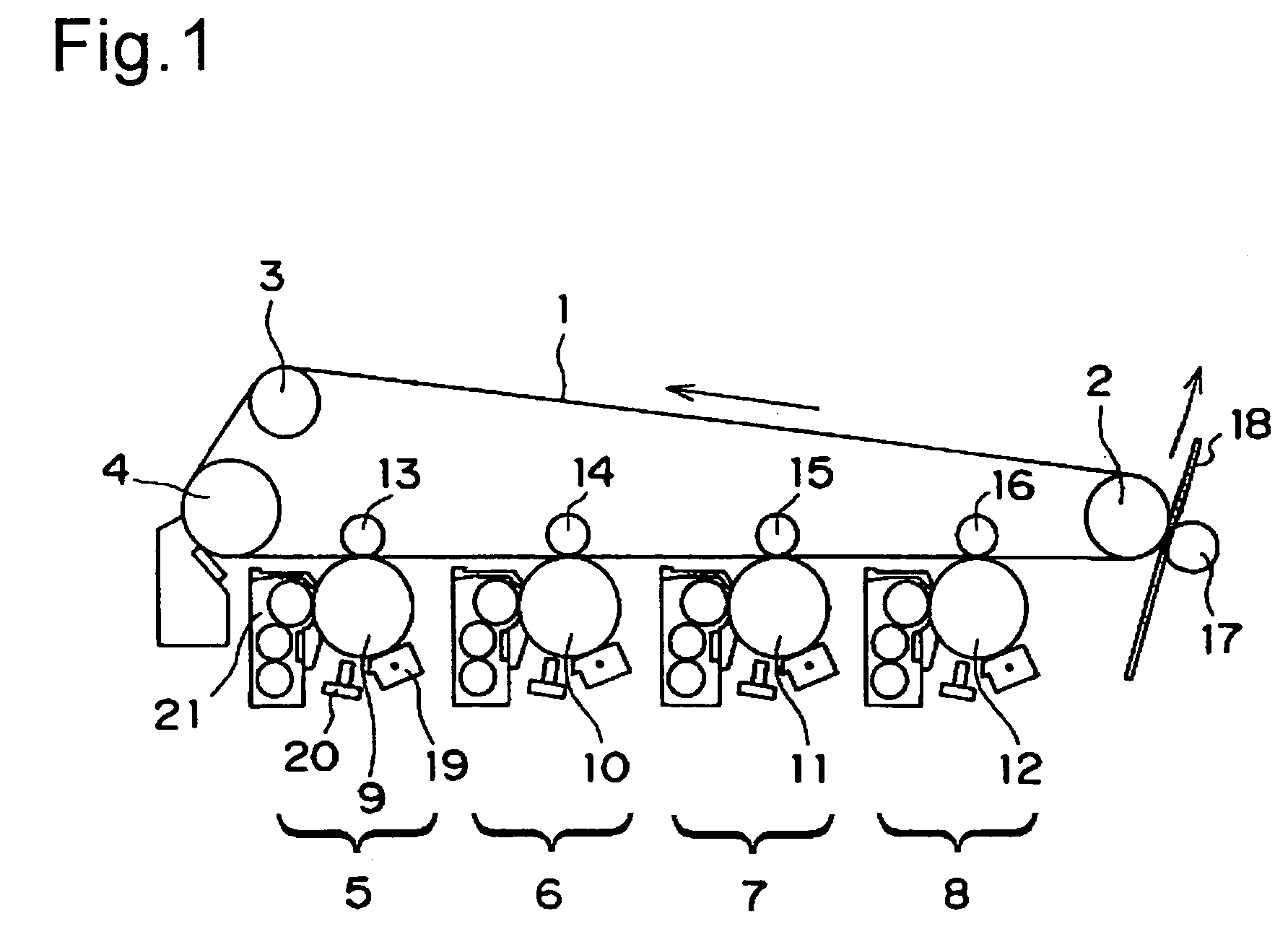

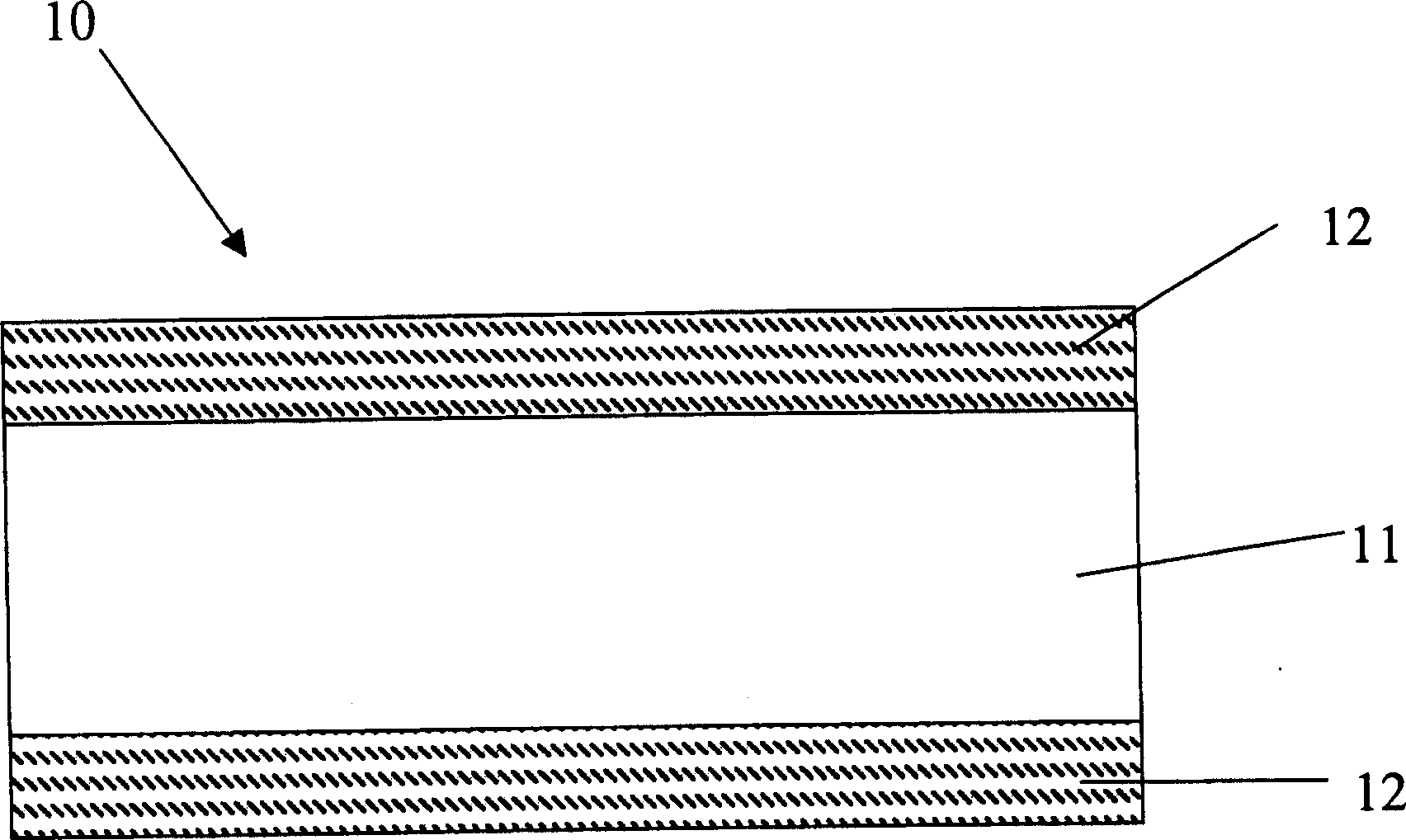

Intermediate transfer medium, film forming liquid for the intermediate transfer medium and image forming apparatus using intermediate transfer medium

InactiveCN1655075AImprove resistance uniformitySynthetic resin layered productsDevelopersOrganic solventPolyamic acid

An intermediate transfer medium including a layer which includes an acidic carbon black including volatile components of from 3.5 to 8.0% by weight; at least one of a water soluble resin having a weight average molecular weight of from 3,000 to 30,000, and a resin dispersant having a weight average molecular weight of from 3,000 to 300,000 which is selected from the group consisting of polyamide acids, polyimides, and block copolymer including a unit containing at least one of a polyamide acid and a polyimide; and a binder resin, wherein a weight ratio (CB / R) of the carbon black (CB) to the at least one (R) of the water soluble resin and the resin dispersant is from 3 / 1 to 10 / 1. A film forming liquid for use in preparing the layer, and an image forming apparatus using the intermediate transfer medium are also provided.

Owner:RICOH KK

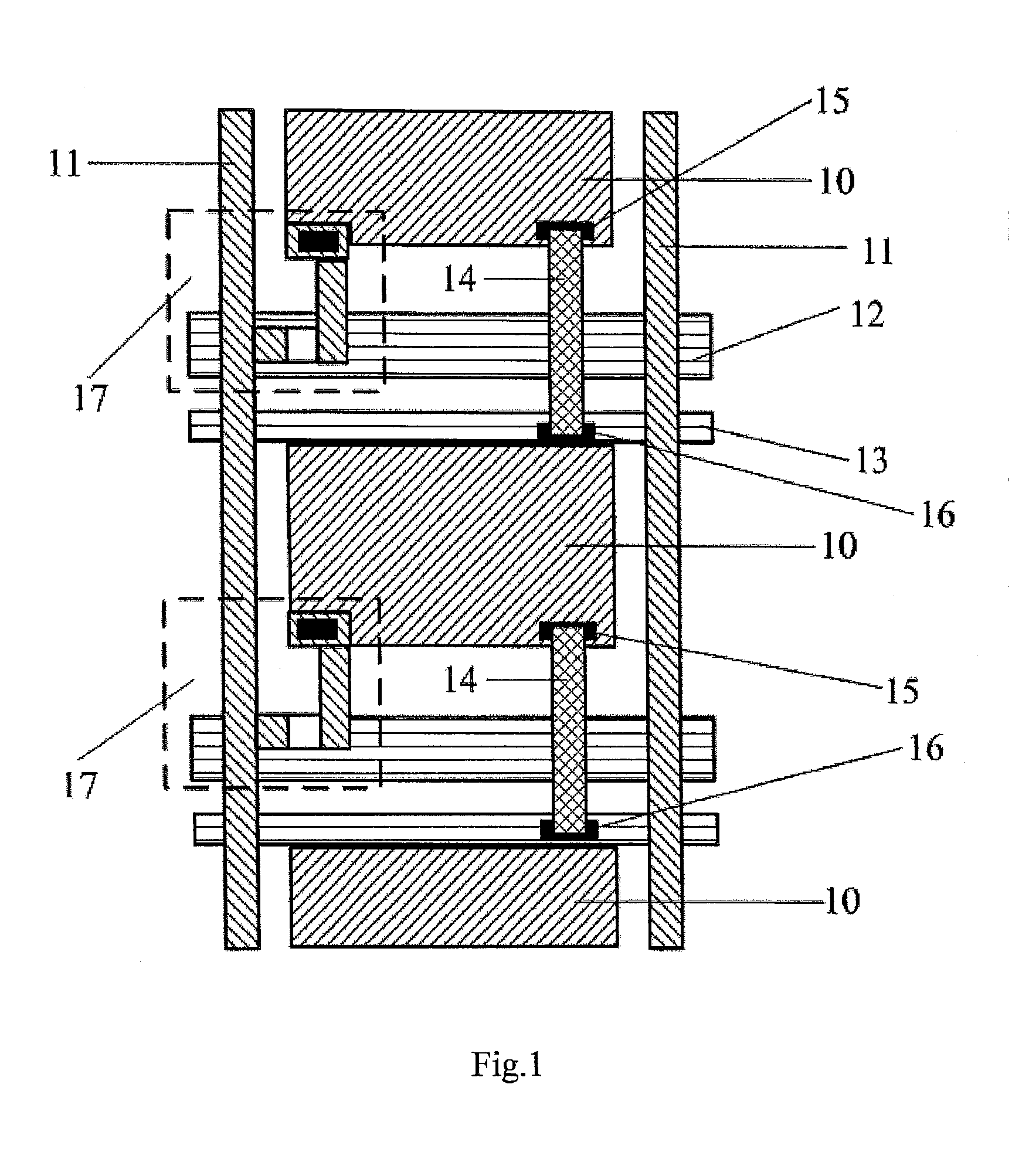

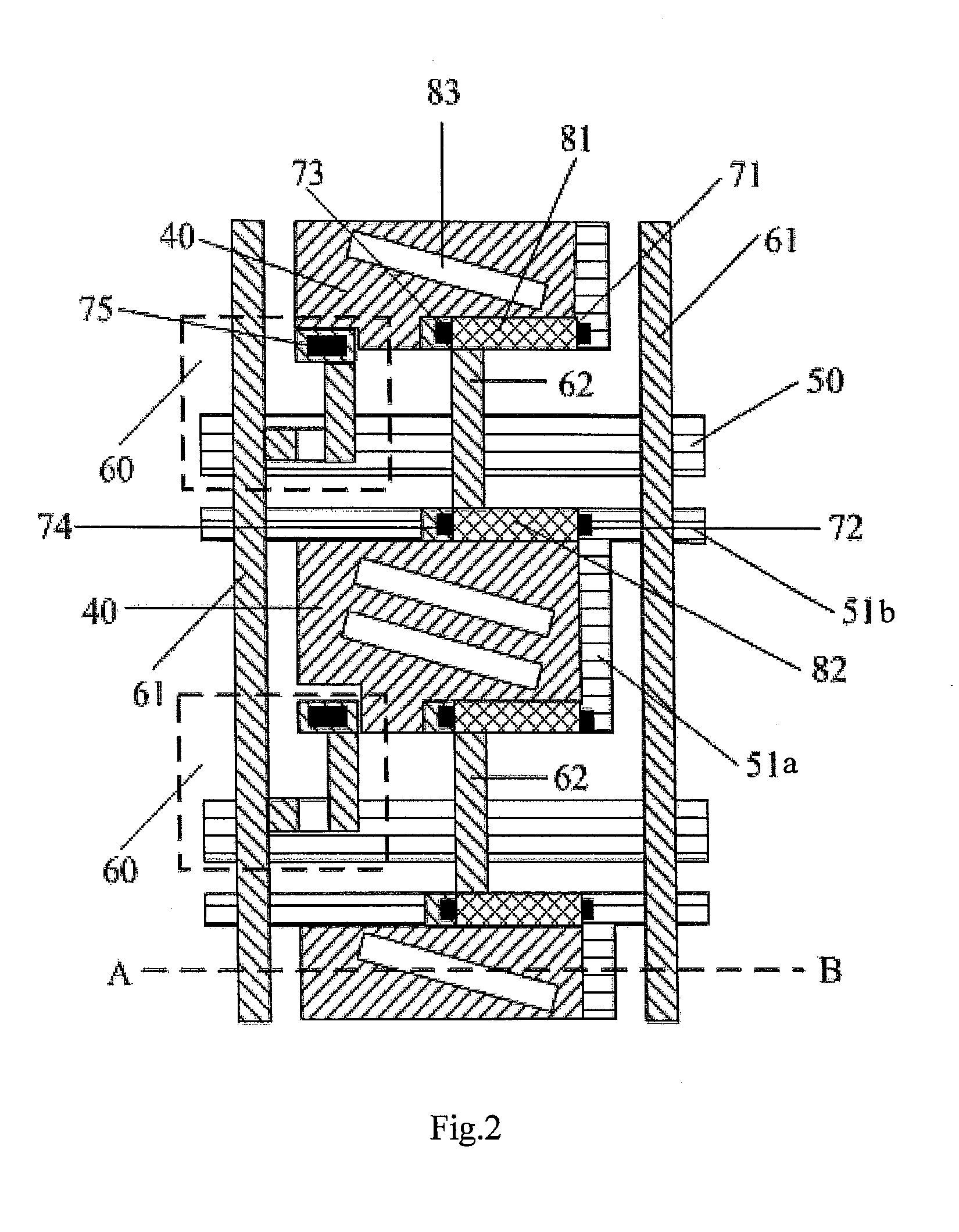

Method for preparing indium tin oxide (ITO) film on resin substrate by using magnetron sputtering

ActiveCN102312208ALow resistivityQuality improvementVacuum evaporation coatingSputtering coatingSputteringVacuum pumping

The present invention discloses a method for preparing an indium tin oxide (ITO) film on a resin substrate by using magnetron sputtering. The method comprises the following concrete steps: a, placing a resin substrate in a loading chamber of a magnetron sputtering device, carrying out vacuum pumping after sealing; b, conveying the resin substrate to a heating chamber, heating the substrate to a temperature of 150-250 DEG C; c, conveying the heated resin substrate to a sputtering chamber, adopting magnetron sputtering manner to carry out ITO film deposition, wherein the cathode direct current power supply input power in the sputtering chamber is 0.6-6 KW according to different ITO surface resistance values; d, conveying the film-coated substrate to a cooling chamber to carry out cooling; e, placing the cooled substrate in an unloading chamber, and unloading the substrate. With adopting the process method, the continuous vertical magnetron sputtering method is adopted for preparing the low-resistivity and high-quality ITO film on the resin substrate, and the prepared ITO film has performances of good resistance uniformity, low resistivity, high transmittance, good chemical stabilityand the like.

Owner:WUHU TOKEN SCI

Laser silver paste used for capacitive touch screen as well as preparation method and use method for laser silver paste

InactiveCN105139919AReasonable formulaImprove resistance uniformityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteWork performance

The invention discloses laser silver paste used for a capacitive touch screen as well as a preparation method and a use method for the laser silver paste. The laser silver paste used for the capacitive touch screen comprises the following raw materials in parts by weight: 60-80 parts of silver powder, 6-10 parts of resin, 22-25 parts of solvent, 0.3-3 parts of toner and 1-5 parts of accessory ingredients, wherein the grain diameter of the silver powder is 0.0005-0.0015 mm. The laser silver paste used for the capacitive touch screen is reasonable in formula, the printing thickness can be controlled to be 4-6 microns, and the laser silver paste is good in resistance uniformity, strong in adhesive force and high in stability; the preparation method provided by the invention is simple in process, easy to implement, and greatly shortens the production period and effectively improves the production efficiency; the use method provided by the invention is simple in process, and the laser silver paste can be attached to the majority of ITO membrane materials and glass substrates; in addition, the laser silver paste is excellent in adhesive force, capable of passing the adhesion test, good in working performance and easy to implement; and the working efficiency is effectively improved, so that the laser silver paste used for the capacitive touch screen can be widely applied.

Owner:DONGGUAN DOMAL ELECTRONICS SCI & TECH

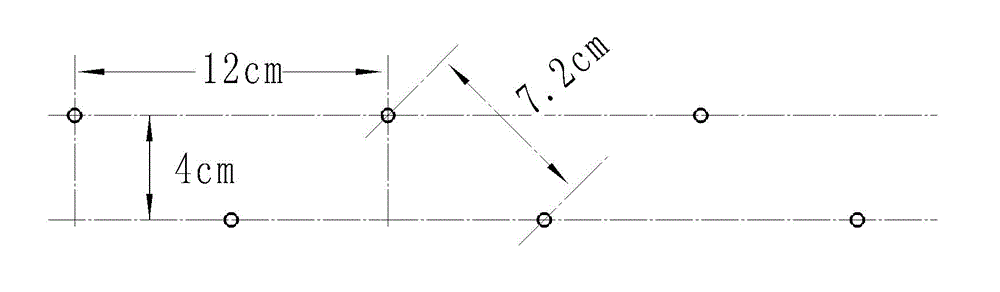

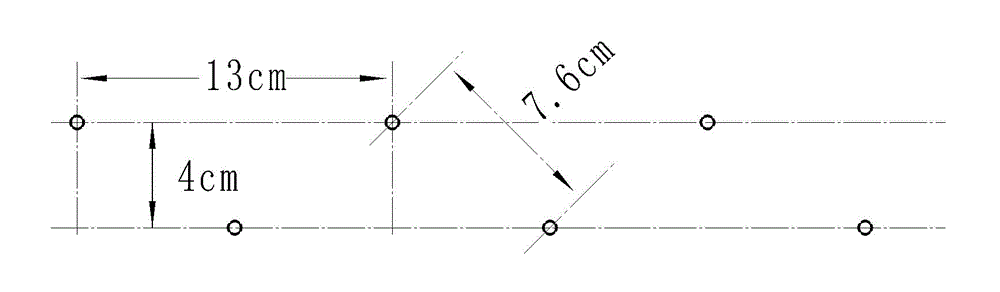

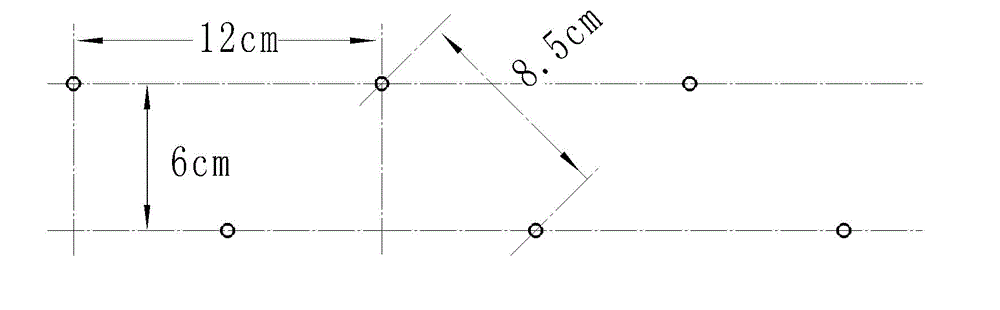

Ultra-narrow-row cotton planting method

The invention discloses an ultra-narrow-row cotton planting method, which is characterized in that in the sowing stage of cotton planting, line spacing of wide rows is controlled to be 70-72cm, line spacing of narrow rows is controlled to be 4-6cm, i.e. an ultra-narrow-row dual-seedling-belt planting mode with line spacing combination of 70-72cm and 4-6cm is adopted, plants between every two narrow rows are in staggered distribution, i.e. triangular distribution, and plant distance of the plants is controlled to be 10-16cm. Compared with the prior art, since the method adopts the ultra narrow row of 4-6cm, but due to the adoption of the triangular distribution between the plants between every two narrow rows, the actual plant distance is enabled to be above 7cm, and the uniform distribution of nutritions of the plants is ensured; and growth difference between adjacent plants is smaller, so that defoliation ripening agent is more uniformly sprayed during harvesting, the defoliating effect is good, the resistance uniformity is good when a mechanical picking head is inserted into cotton plants, and the clear picking rate is generally improved by more than one percentage point during mechanical picking.

Owner:XINJIANG KESHEN AGRI EQUIP SCI&TECH DEV +1

Transfer belt and full color image-forming apparatus equipped therewith

ActiveUS20060062607A1Improve resistance uniformitySufficient conductive propertySynthetic resin layered productsElectrographic process apparatusPolymer scienceElectron

A transfer belt that contains carbon black A, that is acidic carbon black having a pH value of not more than 6 or basic carbon black having a pH value of not less than 8; resin B, that is a polymer capable of serving as an electron-pair donator or as an electron-pair acceptor with respect to carbon black A; and resin C, that is a polymer which neither serves as an electron-pair donator, nor serves as an electron-pair acceptor, with respect to carbon black A, and a full color image-forming apparatus, comprising the above transfer belt, and and a full color image-forming apparatus equipped with the belt.

Owner:KONICA MINOLTA BUSINESS TECH INC

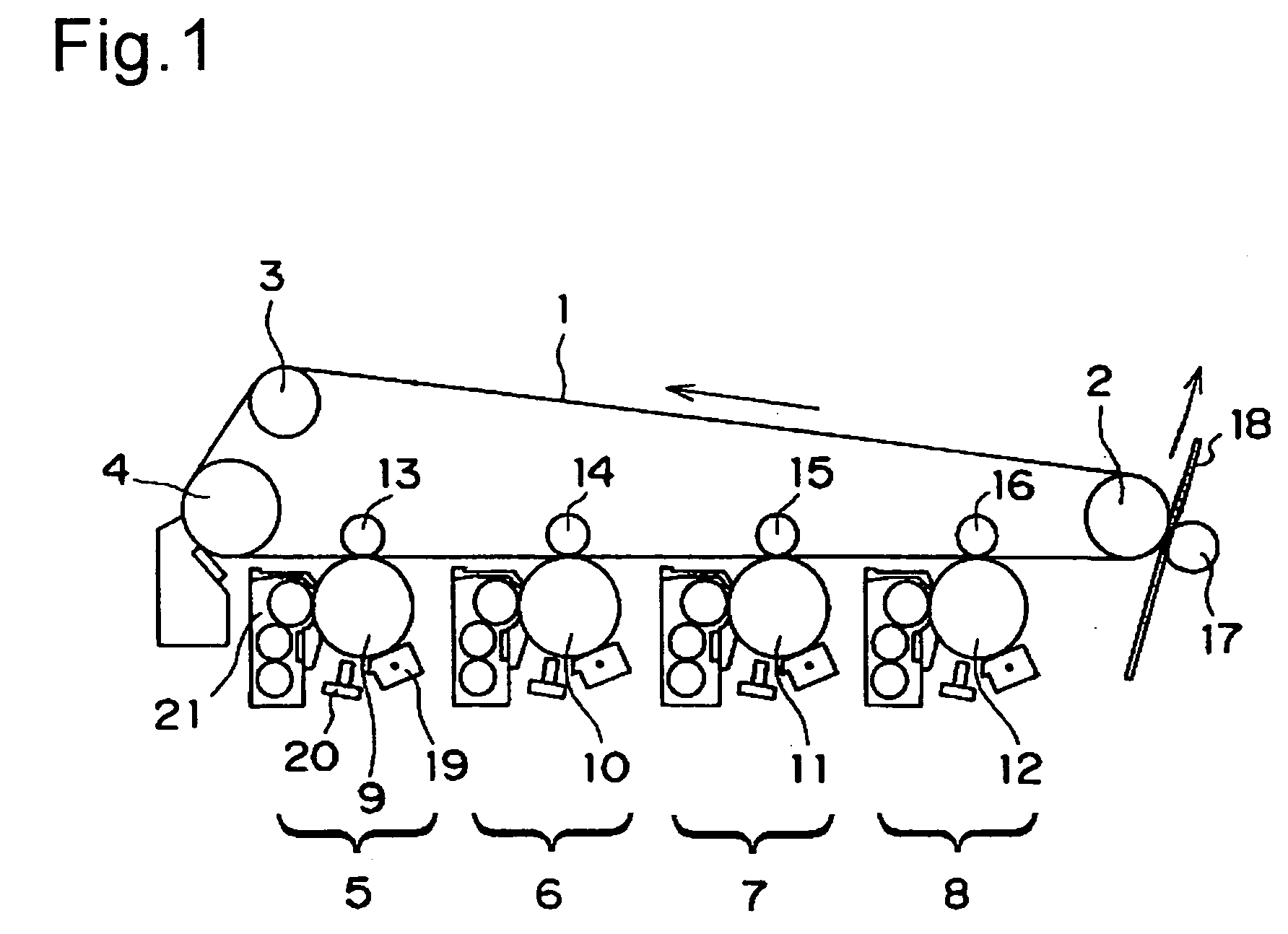

Carbon fiber/gaseous carbon tube/carbon black compound conductive ink and preparation method thereof

The invention belongs to the technical field of conductive inks and particularly relates to a carbon fiber / gaseous carbon tube / carbon black compound conductive ink and a preparation method thereof. The carbon fiber / gaseous carbon tube / carbon black compound conductive ink is composed of, by weight part, 0.1-10 parts of carbon fiber / gaseous carbon tube compound powder, 0.1-20 parts of carbon black,0.1-70 parts of resin adhesives, 0.1-5 parts of dispersant, 0.1-5 parts of flatting agent, 0.1-5 parts of anti-settling agent and 0.1-5 parts of water-repellent agent. The carbon fiber / gaseous carbontube / carbon black compound conductive ink has the advantages of being high in adhesion force, electric conductivity, water resistance, alcohol resistance and the like and achieves uniform conductive uniformity and application attenuation resistance; meanwhile, the carbon fiber / gaseous carbon tube / carbon black compound conductive ink can be applied widely as heating carbon paste, conductive carbonpaste and electromagnetic shielding carbon paste to heating floors, PCB (printed circuit board) carbon oil, electromagnetic shielding coatings and the like.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

Transfer belt and full color image-forming apparatus equipped therewith

ActiveUS7536142B2Improve resistance uniformitySufficient conductive propertySynthetic resin layered productsElectrographic process apparatusPolymer scienceImage formation

A transfer belt that contains carbon black A, that is acidic carbon black having a pH value of not more than 6 or basic carbon black having a pH value of not less than 8; resin B, that is a polymer capable of serving as an electron-pair donator or as an electron-pair acceptor with respect to carbon black A; and resin C, that is a polymer which neither serves as an electron-pair donator, nor serves as an electron-pair acceptor, with respect to carbon black A, and a full color image-forming apparatus, comprising the above transfer belt, and and a full color image-forming apparatus equipped with the belt.

Owner:KONICA MINOLTA BUSINESS TECH INC

Preparation method of heating chip with fused nanometer carbon fibers and wood fibers

The invention discloses a preparation method of a heating chip with fused nanometer carbon fibers and wood fibers. The carbon fibers are sufficiently separated in water through aqueous dispersant. Bymeans of an acid-base balance neutralizing characteristic, a carbon fiber material and a vegetable fiber material are sufficiently fused, and filling of vegetable fiber pores by nanometer-grade graphite conductive particles is realized. The preparation method is characterized in that a specific rule is formed in a fiber material manufacturing process through a current flow direction function, so that resistance uniformity of the heating chip is greatly improved and higher stability is realized.

Owner:浙江沃豪木业科技有限公司

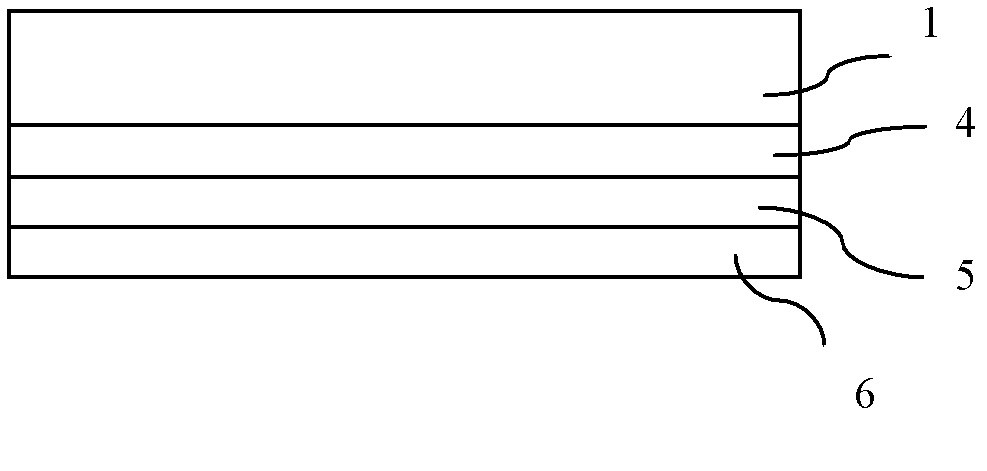

Substrate, epitaxial wafer and semiconductor device

InactiveCN102324435AReduced resistivity uniformityReduce subsequent production costsSemiconductor devicesPolycrystalline siliconSemiconductor

The invention discloses a substrate. The substrate comprises a substrate body and is characterized in that a first silicon dioxide layer is arranged at the back side of the substrate body; a polycrystalline silicon layer is arranged on the surface of the first silicon dioxide layer; and a second polycrystalline silicon layer is arranged on the surface of the polycrystalline layer. The invention has another advantage of being capable of improving the flatness of an epitaxial wafer and increasing the resistivity uniformity of an epitaxial layer.

Owner:SHANGHAI JINGMENG SILICON CORP

Conductive composition exhibiting PTC behavior and over-current protection device using the same

InactiveCN1776825AImprove resistance uniformityImprove machinabilityCurrent responsive resistorsNon-conductive material with dispersed conductive materialConductive polymer compositeMetal foil

The invention discloses a conductive composite material, which includes a plurality of polymers and at least one conductive filler. The plurality of polymers are compatible with each other on a molecular scale, and the shape of the conductive filler is sheet instead of filament. The conductive composite material of the present invention has better electrical properties than conventional conductive composite materials having only a single polymer component. The invention also discloses an overcurrent protection element, which comprises two metal foils and a positive temperature coefficient PTC material layer, and the PTC material layer comprises the conductive composite material.

Owner:POLYTRONICS TECH

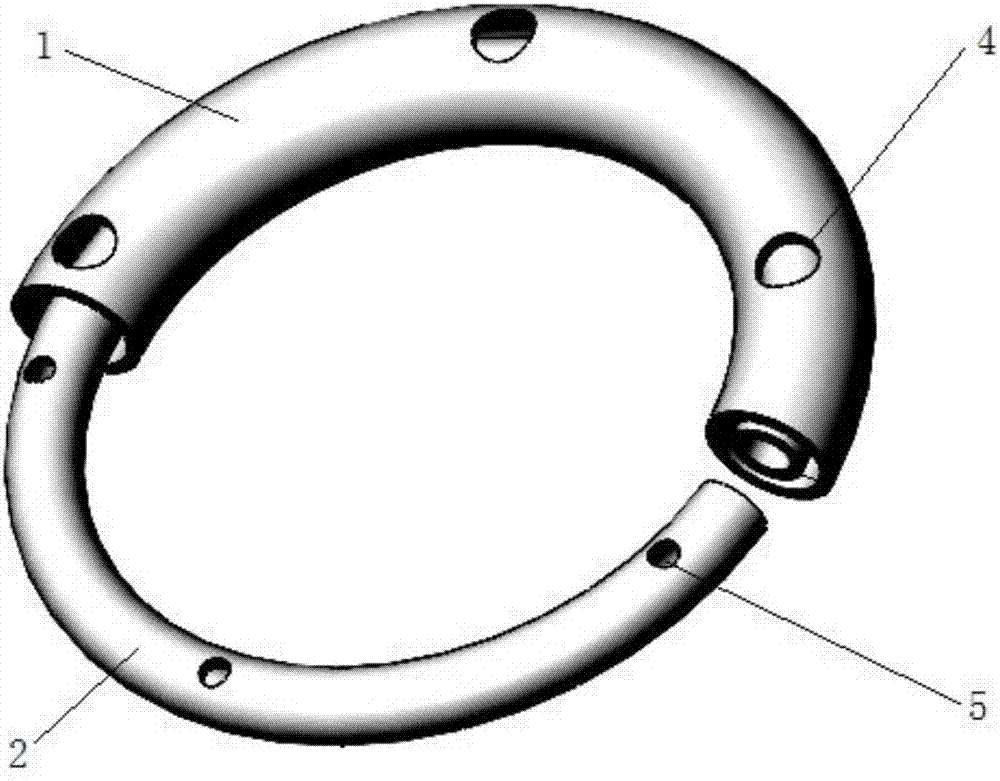

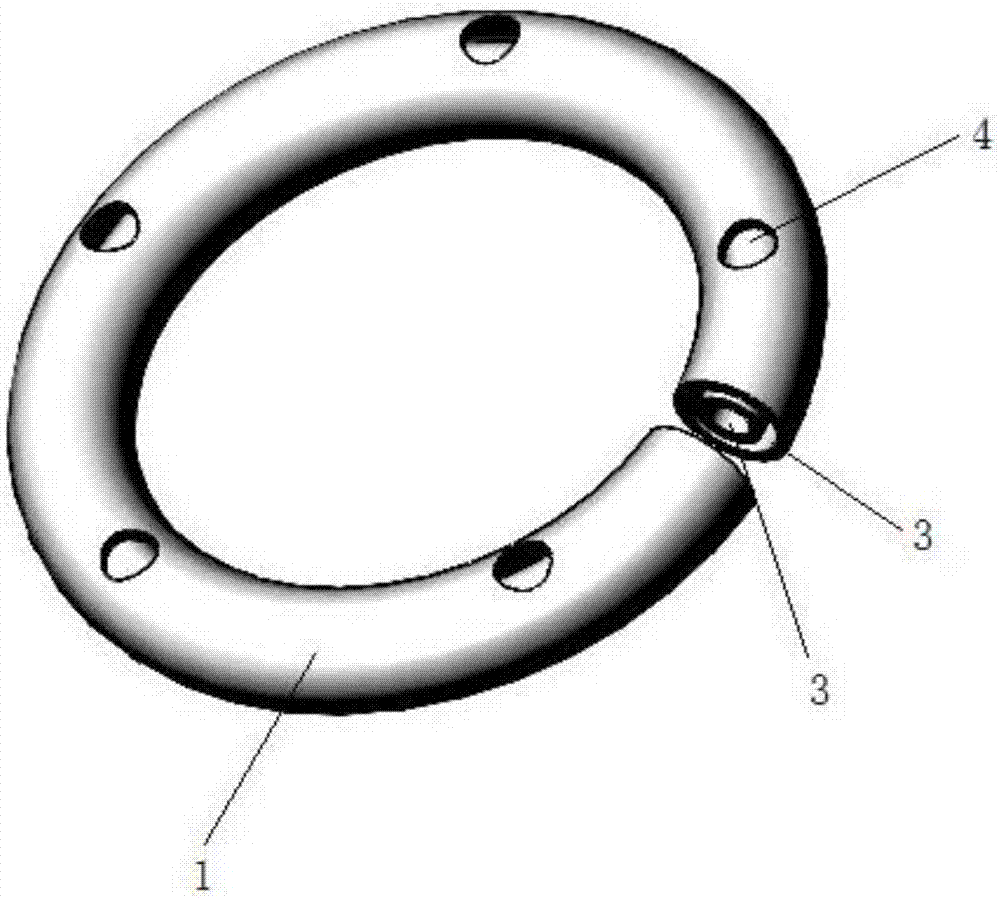

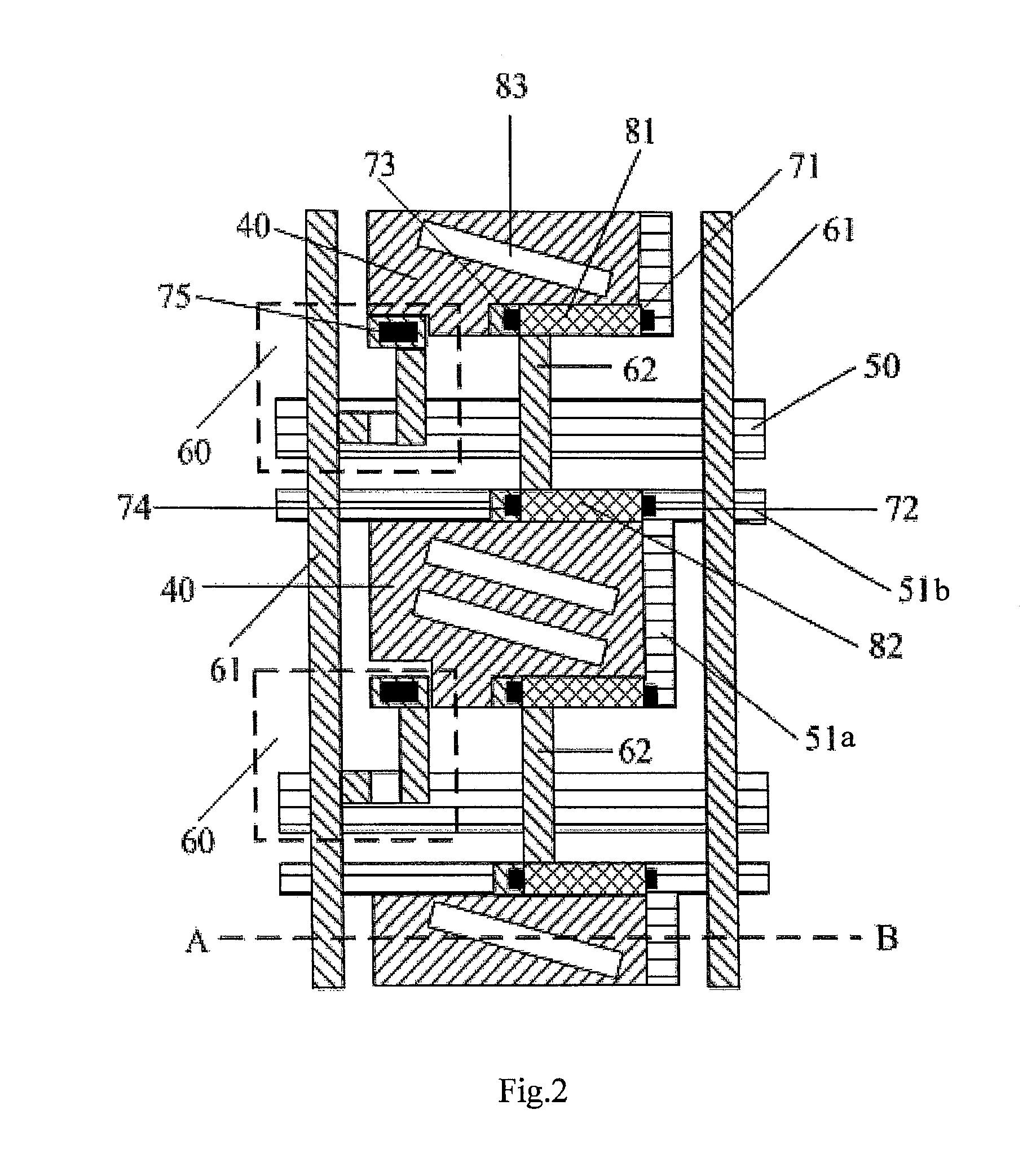

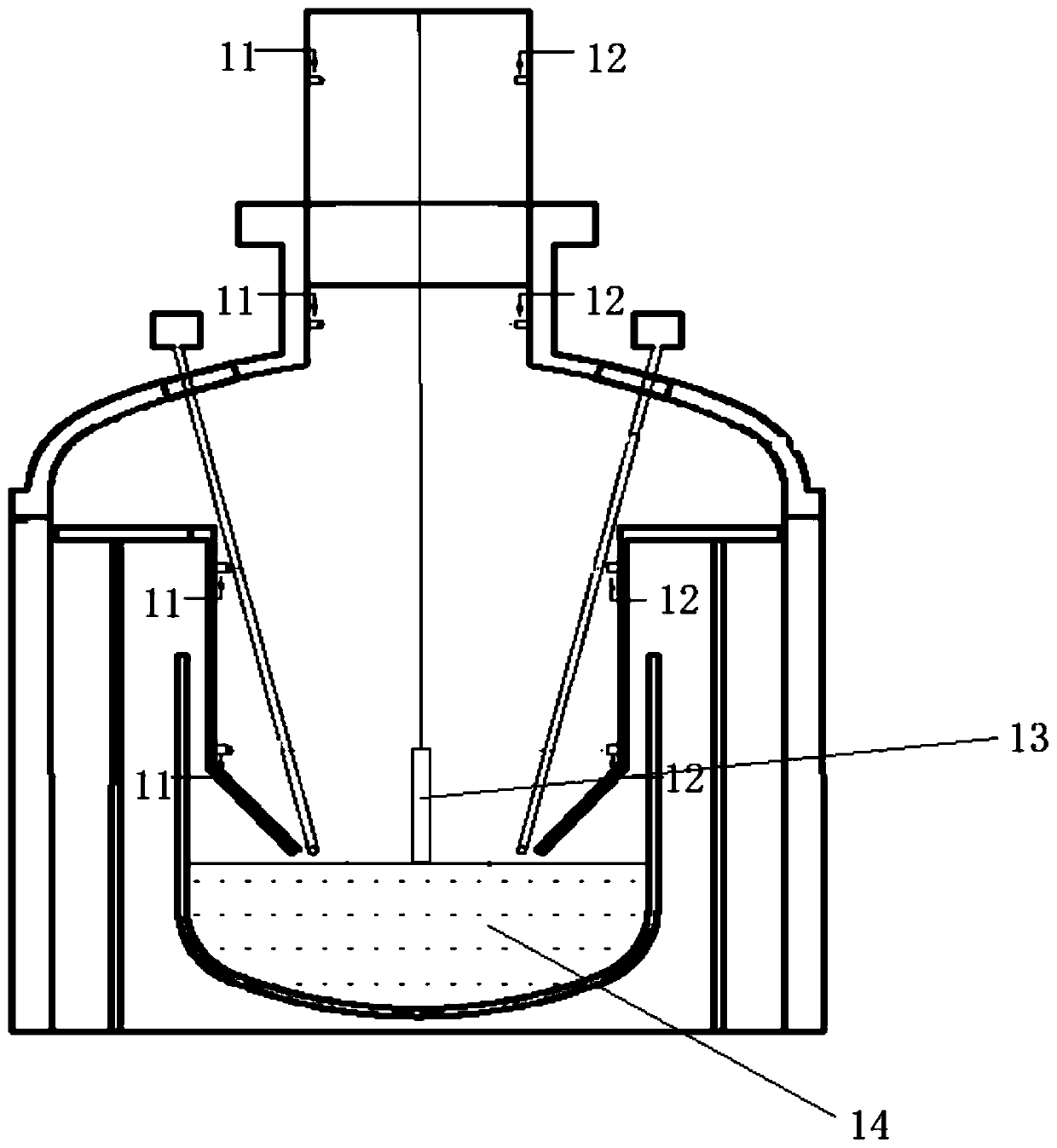

Doping device for improving radial resistivity distribution of float-zone single silicon crystals

ActiveCN106995935AUniform concentrationLess agitationPolycrystalline material growthFinal product manufacturePhysical chemistryEngineering

The invention creatively provides a doping device for improving the radial resistivity distribution of float-zone single silicon crystals. The doping device comprises a main annular pipe and a doped gas annular pipe nested in a pipe cavity of the main annular pipe; mutually independent air inlets are arranged on the main annular pipe and the doped gas annular pipe respectively; a plurality of main gas outlets are formed in the main annular pipe in a circumferential direction; a plurality of doped gas outlets are arranged on the doped gas annular pipe in the circumferential direction; and the main gas outlets and the doped gas outlets are distributed in a staggering manner. The doping device created by the invention can effectively improve the uniformity and the stability of a concentration of the doped gas in a furnace body and ensures the radial resistivity distribution of the grown float-zone single silicon crystals to be more uniform.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

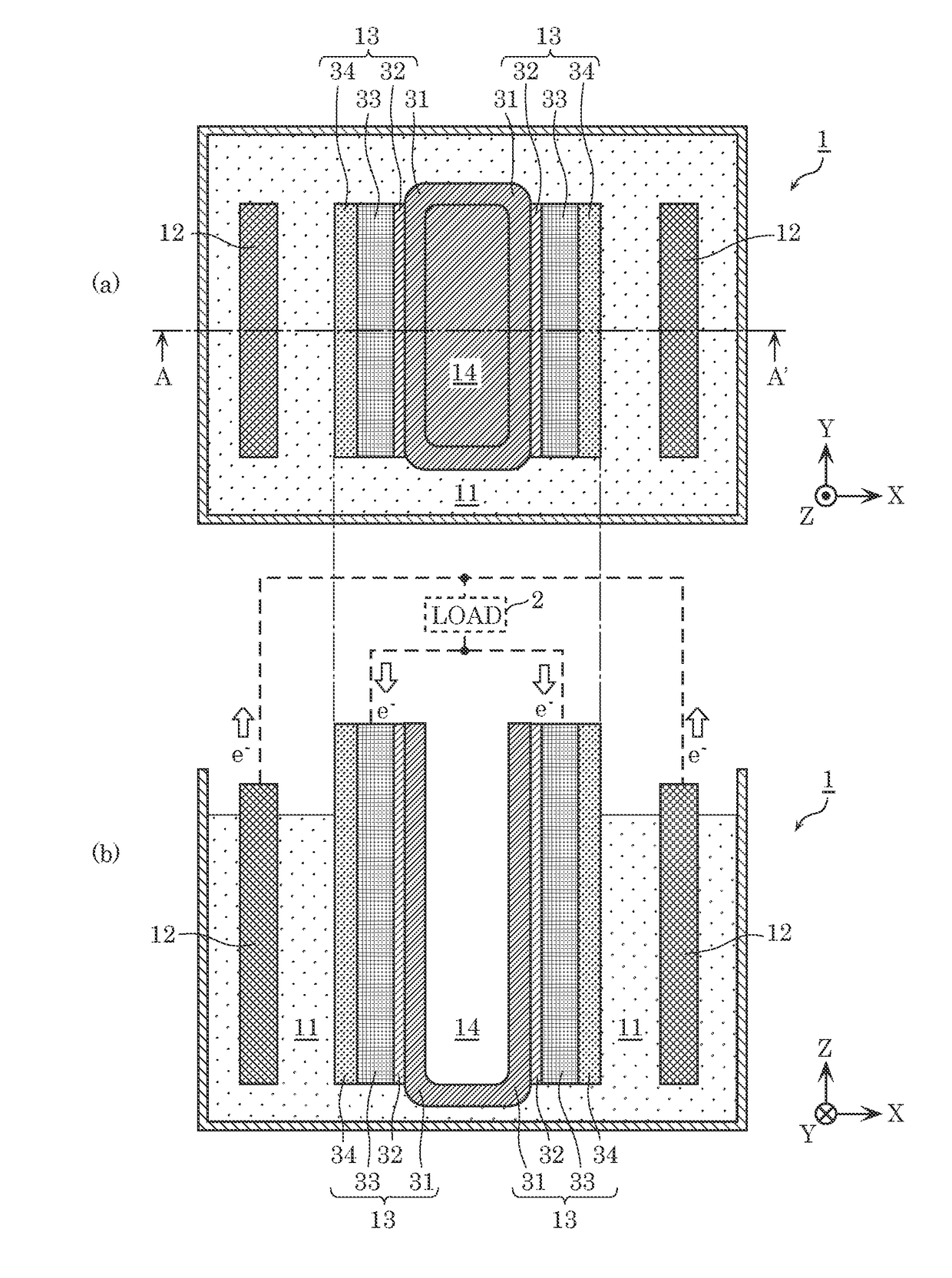

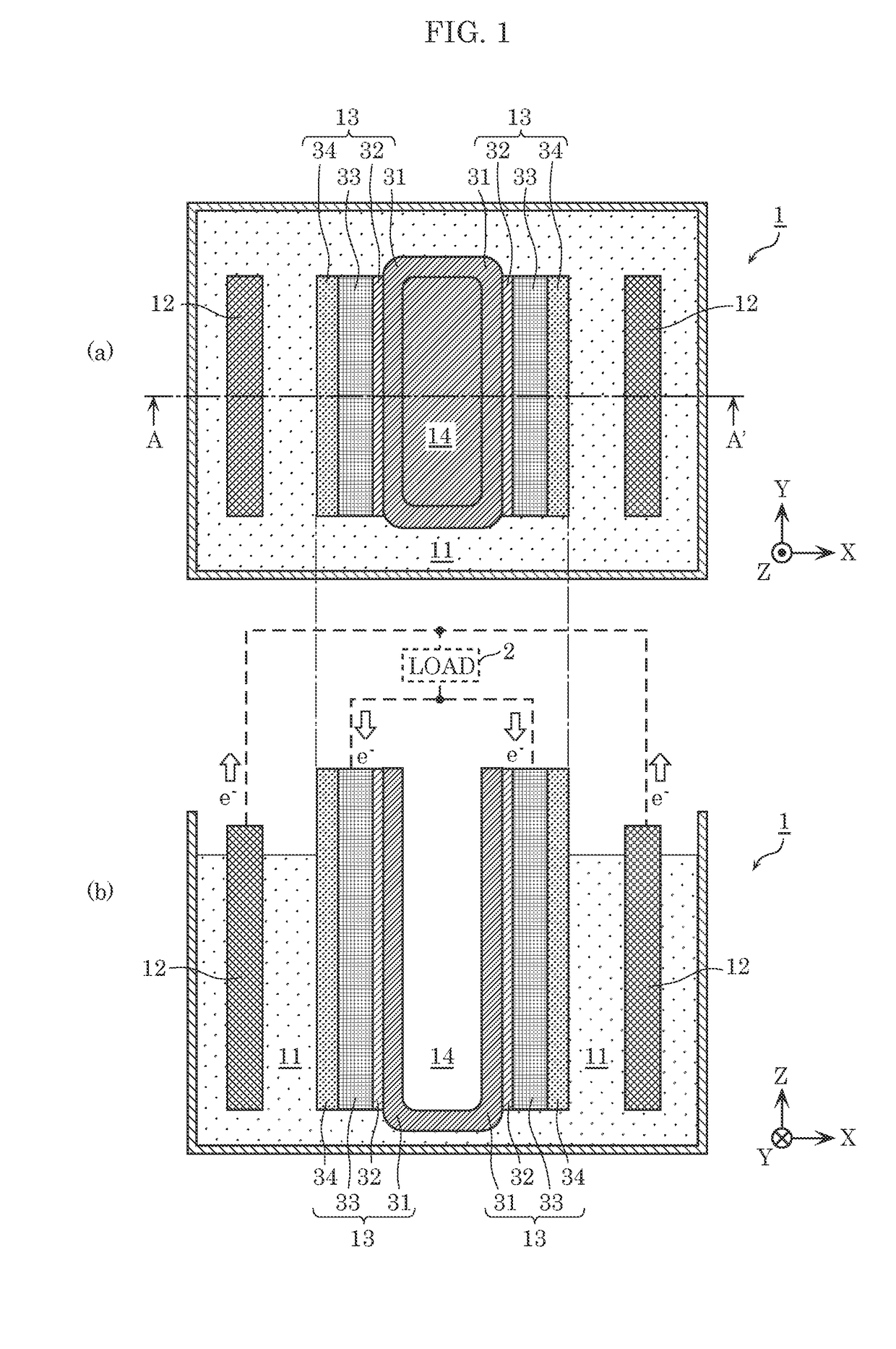

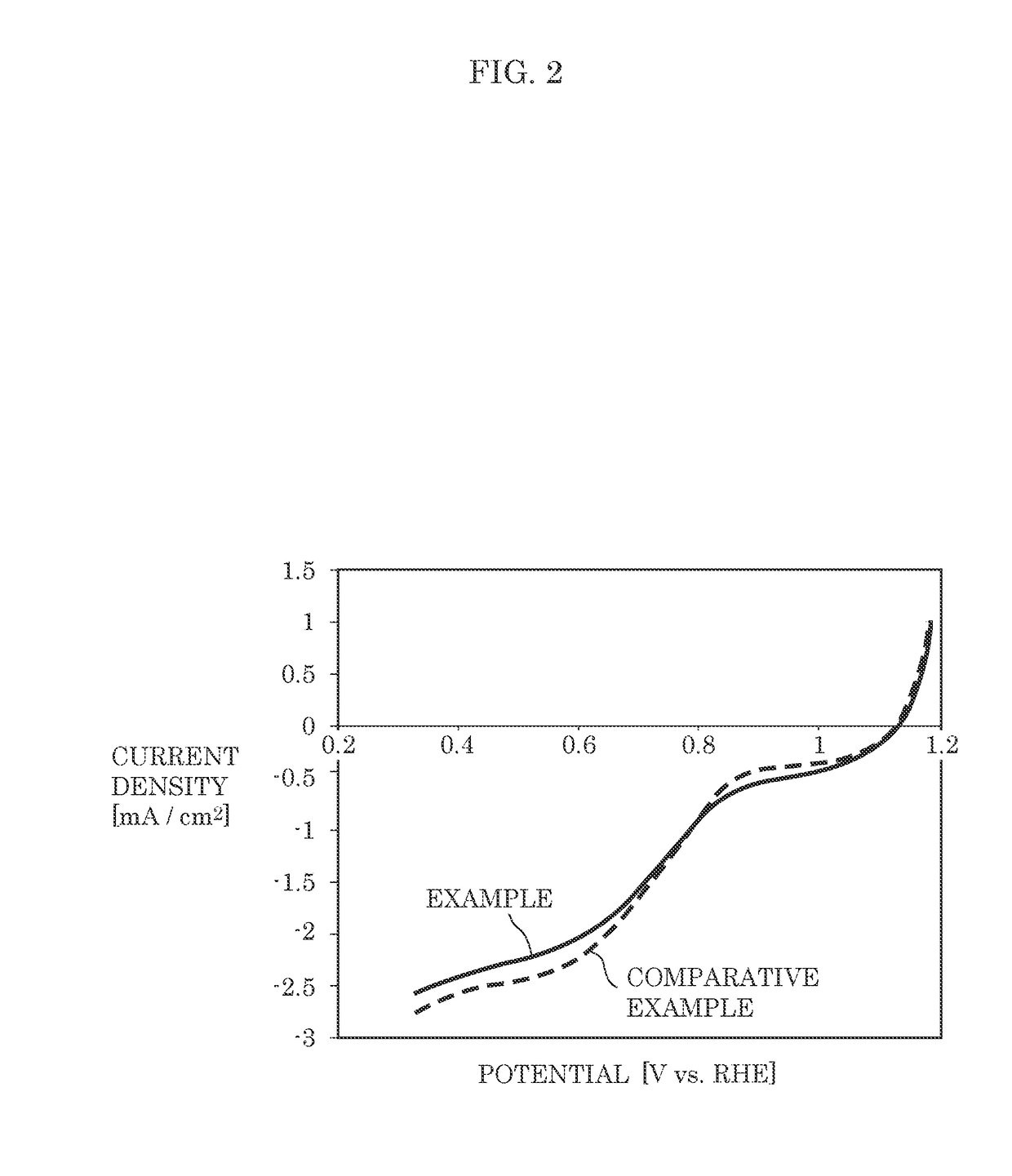

Gas diffusion electrode, electrochemical device, and fuel cell

InactiveUS20170141411A1Uniform high water resistanceImprove resistance uniformityCellsCell electrodesFuel cellsElectrochemical cell

A gas diffusion electrode includes: a water-repellent layer which includes a woven fabric or a non-woven fabric, and which has water repellency; a gas diffusion layer which is stacked on the water-repellent layer; and a catalyst layer which is disposed opposite the water-repellent layer relative to the gas diffusion layer.

Owner:PANASONIC CORP

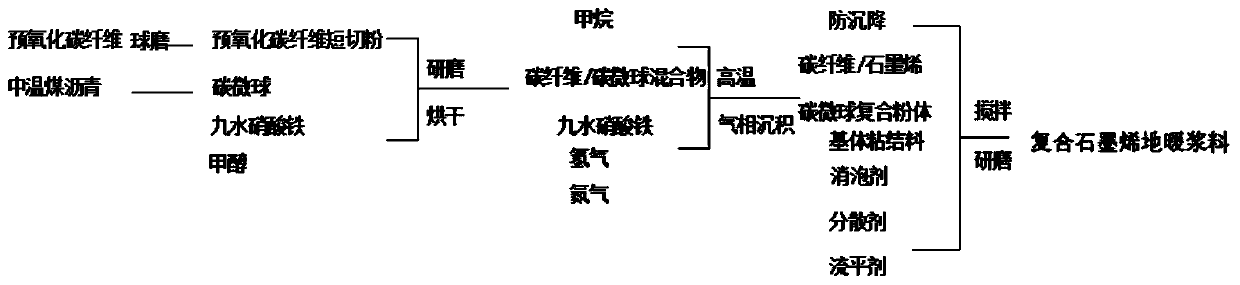

Composite graphene underfloor heating slurry and preparation method thereof

ActiveCN109749519AImprove adhesionImprove conductivityInksHeating element materialsFiberUltrasound attenuation

The invention belongs to the technical field of the underfloor heating slurry, and specifically relates to a composite graphene underfloor heating slurry and a preparation method thereof. The composite graphene underfloor heating slurry is prepared from the following raw materials in parts by weight: 0.1-30 parts of carbon fiber / graphene / carbon microsphere powder, 0.1-70 parts of a matrix bindingmaterial, 0.1-5 parts of a dispersing agent, 0.1-5 parts of a flatting agent, 0.1-5 parts of a precipitator, and 0.1-1 part of a defoaming agent. The composite graphene underfloor heating slurry prepared by adopting the carbon fiber / graphene / carbon microsphere powder has characteristics of good adhesive force, high conductivity, water resistance and alcohol resistance, and has excellent conductiveuniformity, and attenuation resistance.

Owner:浙江格来菲科技有限公司

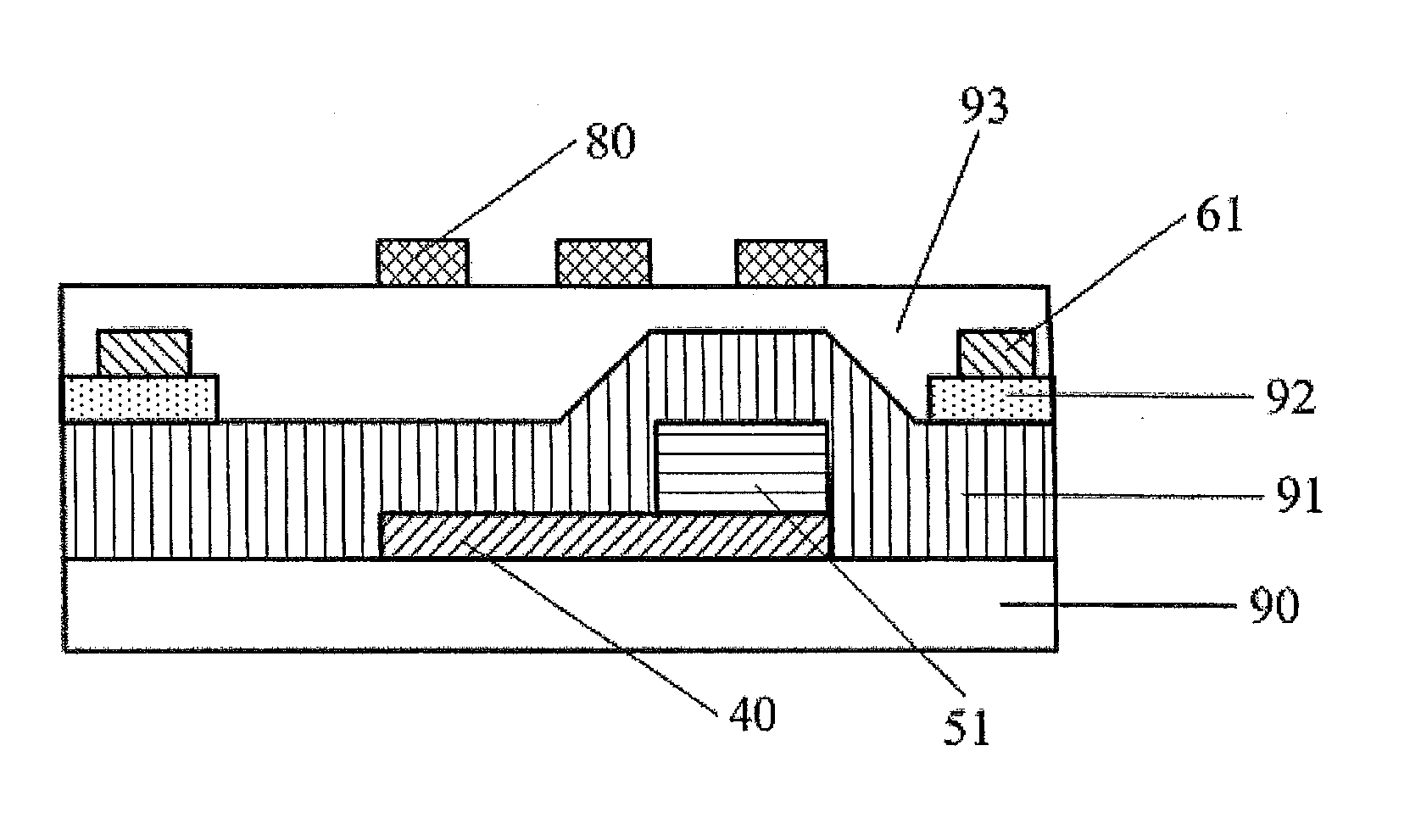

Organic light emitting display device and manufacturing method for the same

ActiveUS8643019B2Simple manufacturing processImprove resistance uniformityTransistorSolid-state devicesOrganic light emitting deviceDisplay device

An organic light emitting display device may comprises a thin film transistor including an active layer, a gate electrode including a gate lower electrode and a gate upper electrode, a source electrode, a drain electrode, and an organic light emitting device electrically connected to the thin film transistor. A pixel electrode formed of the same material and in the same layer as the gate lower electrode, an intermediate layer including a light emitting layer, and an opposed electrode are sequentially deposited. A first pad electrode is formed in the same layer as the gate lower electrode, a second pad electrode is formed on at least a part of the first pad electrode and in the same layer as the gate upper electrode, and a third pad electrode contacts at least a part of the second pad electrode and is formed in the same layer as the source electrode.

Owner:SAMSUNG DISPLAY CO LTD

Array substrate and method for manufacturing the same, display apparatus

ActiveUS9123592B1Reduce resistanceImprove resistance uniformitySemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

An array substrate is disclosed. The array substrate comprises a substrate, a plurality of common electrodes formed on the substrate, a plurality of gate signal lines formed above the common electrodes, and a plurality of common electrode signal line units corresponding to the plurality of common electrodes, respectively. The plurality of common electrode signal line units are formed on the corresponding common electrodes, respectively. Each of the common electrode signal line units comprises a first common electrode signal line perpendicular to the gate signal line and a second common electrode signal line parallel to the gate signal line. The first and second common electrode signal lines are made of metal and cross with each other and are electrically connected to each other. Two adjacent common electrode signal line units are electrically connected by a bridge line. The present disclosure also relates to a method for manufacturing the array substrate and a display apparatus.

Owner:BOE TECH GRP CO LTD +1

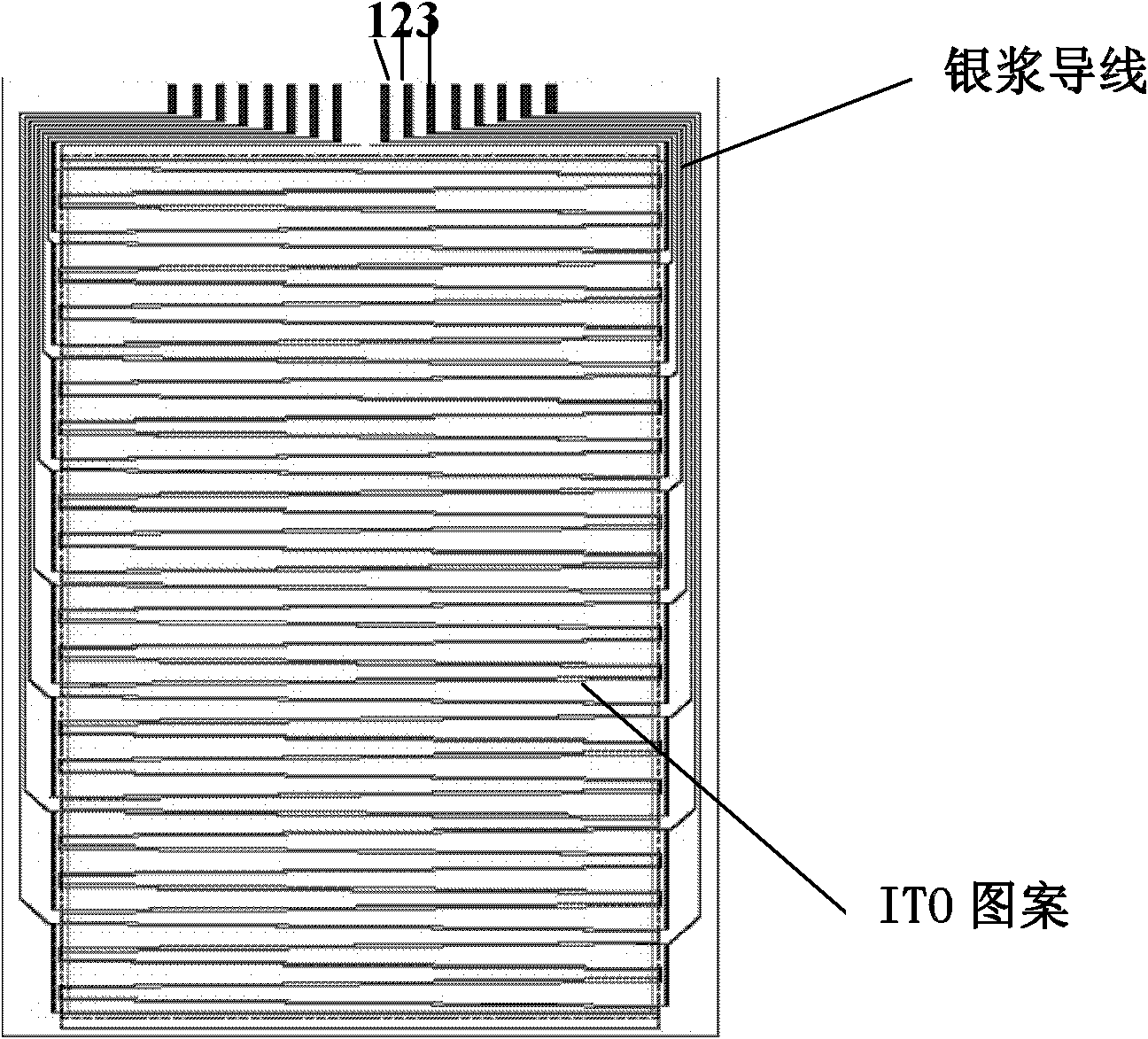

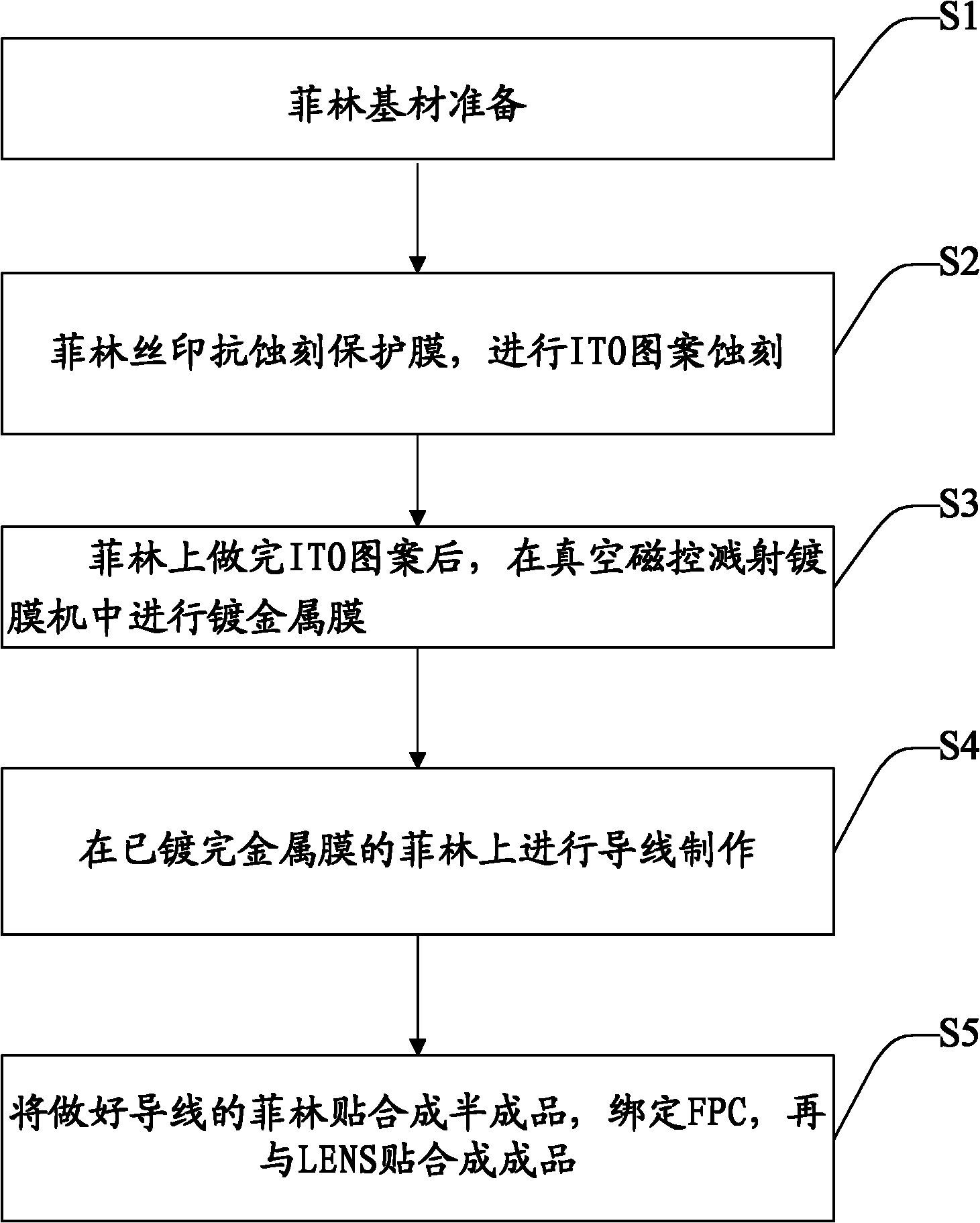

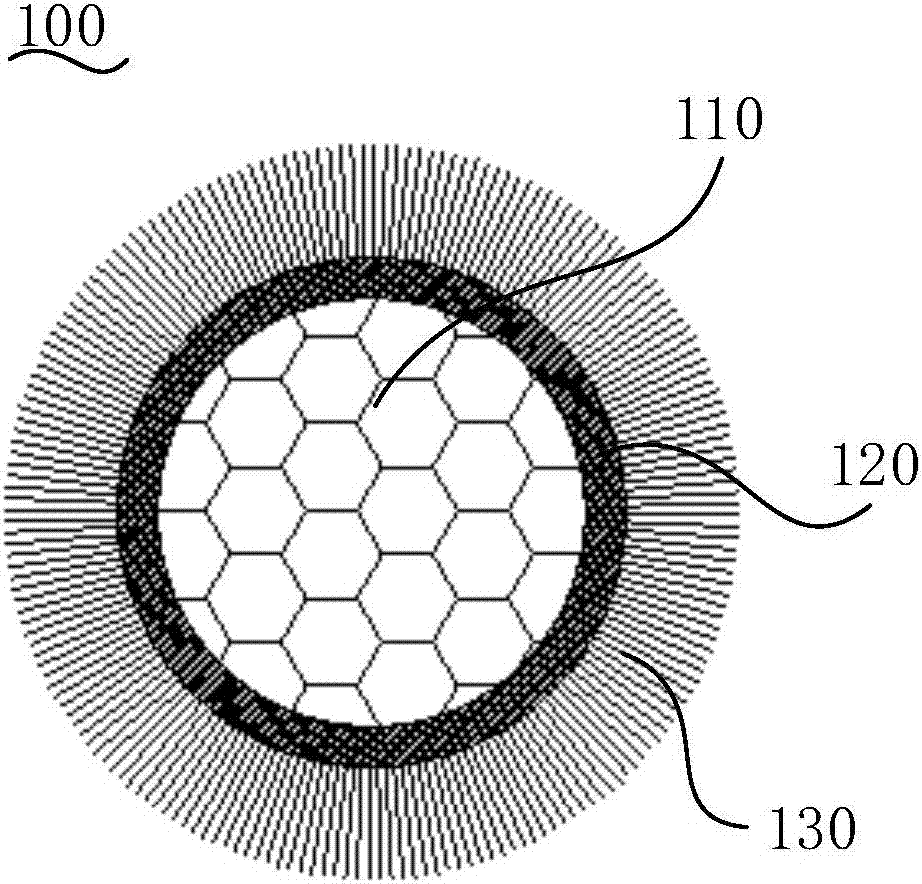

Capacitance touch screen and manufacture method thereof

InactiveCN102221949AReduce foulingFine and uniform linesVacuum evaporation coatingSputtering coatingSilver pasteCapacitance

The invention discloses a capacitance touch screen manufacture method, which comprises the steps as follows: after a pattern is etched on a film, a guide wire is manufactured on the surrounding of the pattern by adopting a way of plating a metal film; and then the film is fit with an LENS. The metal guide wire manufactured by adopting the plating way has thickness between 0.3Mu m and 0.6Mu m, which is far smaller than the thickness of 10Mu m of silk-screen silver paste, thus being capable of reducing bad bubbles caused by large thickness during fitting. The guide wire manufactured by the capacitance touch screen manufacture method by adopting the way of plating has fine and uniform lines, which are far higher than that of the silk-screen silver paste, and has good resistance uniformity, thus greatly improving the performances of the touch screen. The distances between the silk-screen silver paste lead wires of the prior art are usually about 80Mu m due to the limitation of a silk-screening technology, however, the distances between the lead wires manufactured by adopting the plating method can be reduced to be 25Mu m, thus having a larger touch visual area on the touch screen with the same size. The invention also discloses a capacitance touch screen.

Owner:TRULY OPTO ELECTRONICS

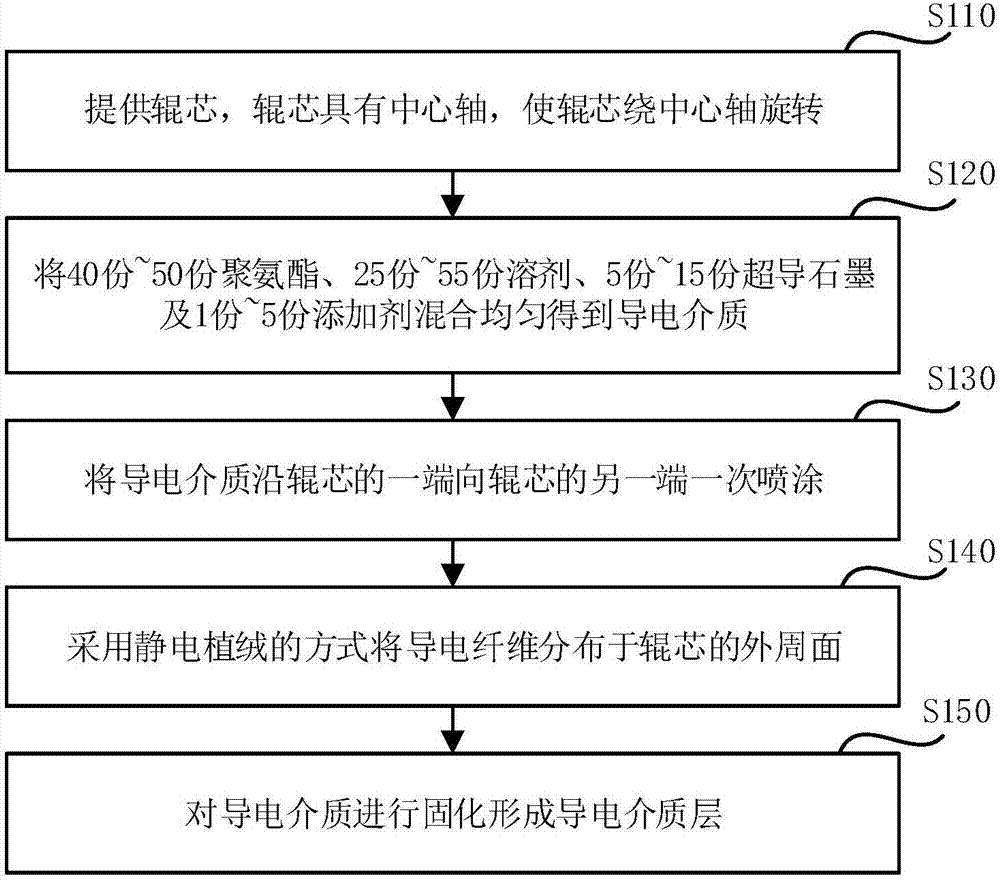

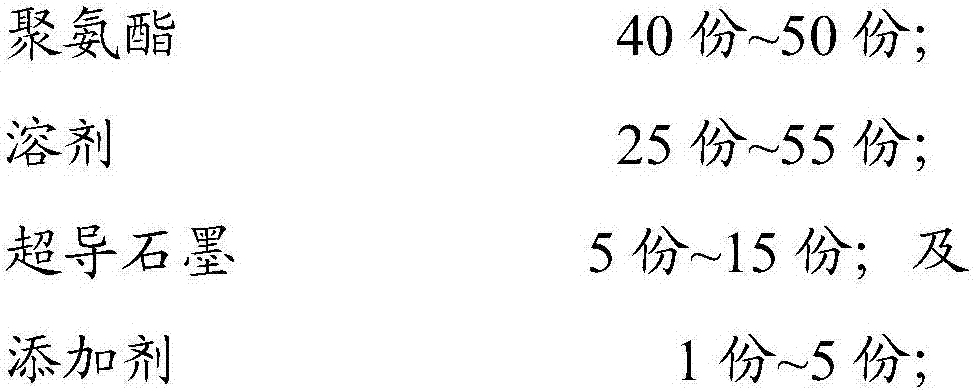

Electric conduction flocking roller and preparation method thereof

ActiveCN107163548ALittle effect on bonding propertiesLower the resistance valueElectrography/magnetographyFiberElectrical resistance and conductance

The present invention relates to an electric conduction flocking roller and a preparation method thereof. The electric conduction flocking roller comprises a roller core, an electric conduction medium layer and electric conduction fiber penetrating through the electric conduction medium layer and connected to the roller core, wherein the electric conduction medium layer is formed by curing an electric conduction medium, the electric conduction medium layer comprises, by mass, 40-50 parts of polyurethane, 25-55 parts of a solvent, 5-15 parts of superconducting graphite and 1-5 parts of an additive, the solvent is at least one selected from butyl acetate, ethyl acetate and propyl acetate, and the additive is at least one selected from 1-methoxy-2-propyl acetate, methyl isobutyl ketone and dibasic acid ester. According to the present invention, the superconducting graphite has good dispersibility in the polyurethane and the solvent, such that the prepared electric conduction medium layer has advantages of low resistance, good resistance uniformity, and low resistance difference; and the influence of the adding of the superconducting graphite on the adhesion of the polyurethane is low, such that the excellent adhesion of the electric conduction medium layer is ensured, and the hair loss of the electric conduction fiber is reduced.

Owner:SHENZHEN FANCY CREATION INDAL

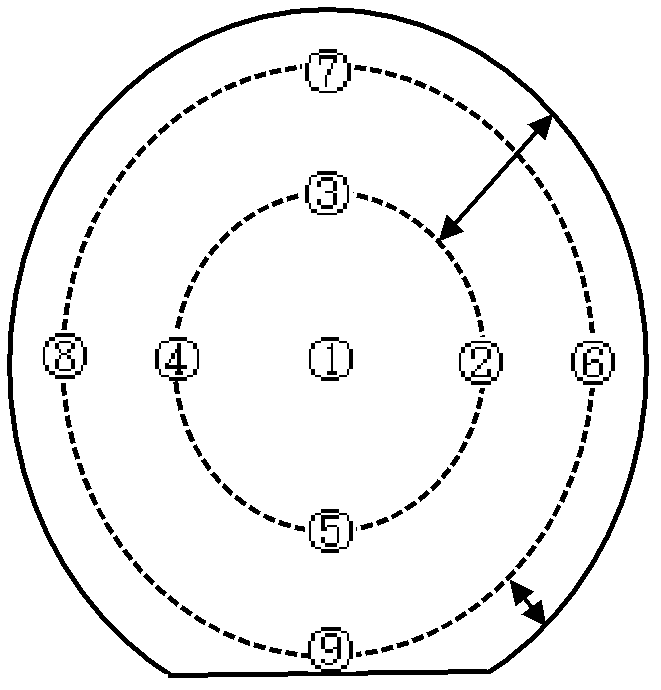

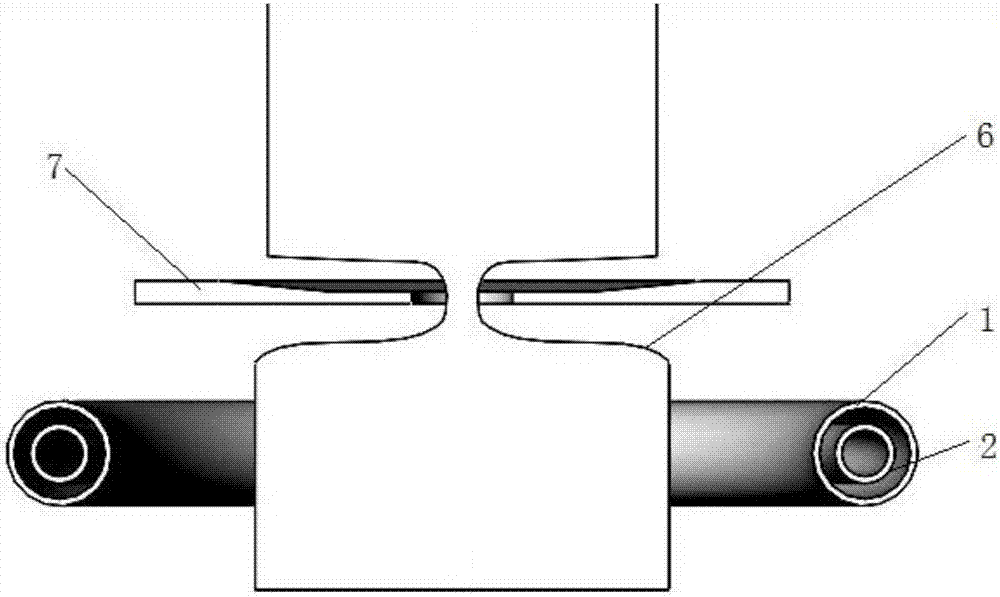

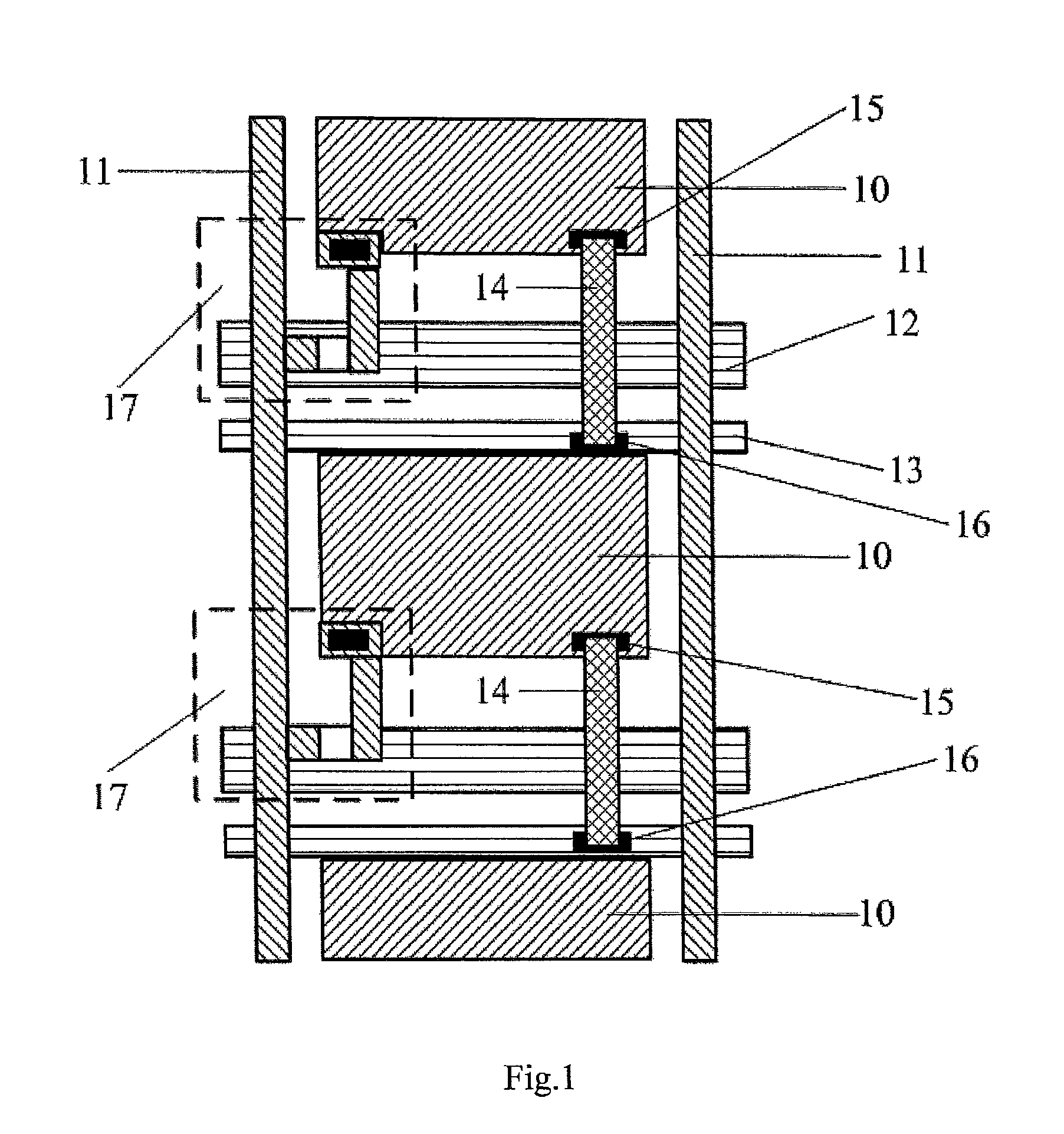

Heating bearing platform of laser annealing machine table

InactiveCN104377158ARaise the preheating temperatureImprove resistance uniformitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringHeating temperature

The invention discloses a heating bearing platform of a laser annealing machine table. A synchronously-moving combined heating bearing platform body is formed by arranging a second heating bearing platform body on the periphery of a first heating bearing platform in a surrounding mode. Heating is independently carried out through heating units arranged on the first heating bearing platform body and the second heating bearing platform body respectively, the heating temperature of the second heating bearing platform body is higher than that of the first heating bearing platform body, the heat dissipation temperature loss of a silicon wafer edge area borne by the first heating bearing platform body and the second heating bearing platform body can be offset, the preheating temperature of the silicon wafer edge area is increased, and therefore the phenomenon that when the laser annealing technology is carried out, the square resistance value is relatively high due to the low silicon wafer edge temperature is eliminated, and the improvement of the on-chip resistance in a silicon wafer and the overall device performance are improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for producing novel substrate, epitaxial wafer and semiconductor device

InactiveCN102412124ALow growth temperatureImprove resistance uniformitySemiconductor/solid-state device manufacturingCrystallographyDevice material

The invention discloses a method for producing a novel substrate. The novel substrate comprises a substrate body and is characterized in that: the surface of the substrate body is provided with a monocrystalline silicon layer; and the monocrystalline silicon layer is formed by depositing monocrystalline silicon which is generated by reacting trichlorosilane and hydrogen at the temperature of between 900 and 1,050 DEG C on the surface of the substrate body. The resistance uniformity of the epitaxial wafer which is produced by using the novel substrate is less than 1.5 percent. Compared with the epitaxial wafer which is not produced by using the novel substrate, the epitaxial wafer has the advantages that the resistance uniformity value of the epitaxial wafer can be reduced by 1 percent. By using the novel substrate, the subsequent production cost can be reduced and product quality can be improved.

Owner:SHANGHAI JINGMENG SILICON CORP

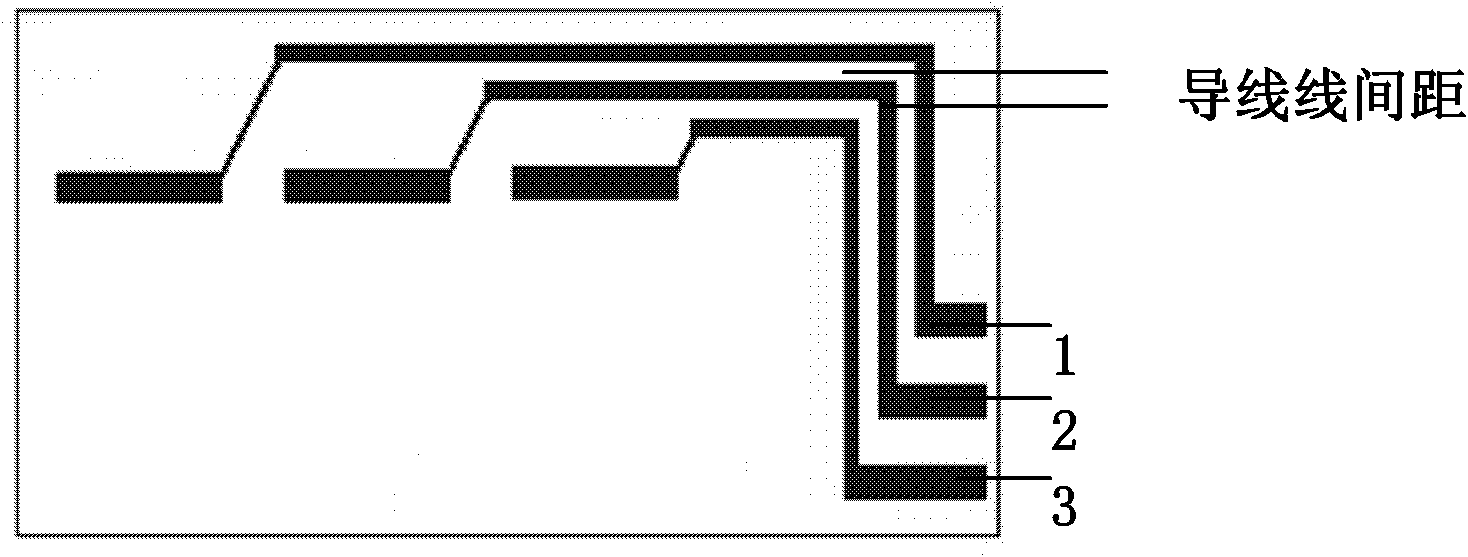

Special conductive filament printing silver slurry for capacitive touch screen and preparation and application methods of special conductive filament printing silver slurry

InactiveCN105070349AReasonable formulaImprove resistance uniformityNon-conductive material with dispersed conductive materialCable/conductor manufactureWork performanceIndium tin oxide

The invention discloses special conductive filament printing silver slurry for a capacitive touch screen and preparation and application methods of the special conductive filament printing silver slurry. The special conductive filament printing silver slurry for the capacitive touch screen comprises the following components in parts by weight: 60-80 parts of silver powder, 6-10 parts of vinyl resin, 22-25 parts of a solvent, 0.5-3 parts of a toner and 1-5 parts of an assistant, wherein the particle size of the silver powder is 0.0005-0.002mm. The printing silver slurry disclosed by the invention is reasonable in formula; the printing thickness can be controlled at 4-6 microns; the special conductive filament printing silver slurry is good in resistance uniformity, high in adhesive force and high in stability; the width of a printed circuit is greater than 0.06mm; the printing silver slurry is especially suitable for special conductive filament printing for the capacitive touch screen; the processes of the preparation and application methods disclosed by the invention are simple and easy to realize; the production efficiency is effectively improved; the silver slurry is relatively well adhered to most of indium-tin oxide (ITO) film materials and glass substrates; and the special conductive filament printing silver slurry is excellent in adhesive force, good in working performance and beneficial to wide popularization.

Owner:DONGGUAN DOMAL ELECTRONICS SCI & TECH

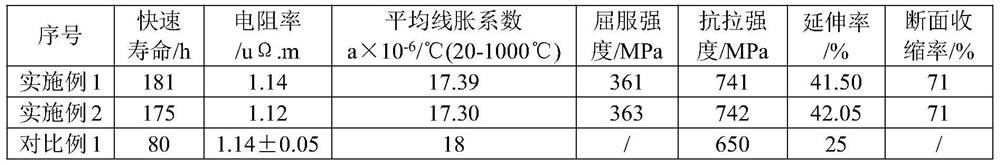

Nickel-chromium series high-resistance electrothermal alloy and preparation method thereof

ActiveCN113073234AImprove antioxidant capacityHigh resistivityTemperature control deviceFurnace typesElectrical resistance and conductanceNichrome

The invention belongs to the technical field of nickel-chromium high-resistance electrothermal alloys, and particularly relates to a nickel-chromium high-resistance electrothermal alloy and a preparation method thereof. The technical problem to be solved is to provide the nickel-chromium series high-resistance electrothermal alloy which is long in service life and excellent in mechanical property under a high-temperature condition and the preparation method of the nickel-chromium series high-resistance electrothermal alloy. The nickel-chromium series high-resistance electrothermal alloy comprises the following chemical components including, by weight, less than or equal to 0.08% of C, 0.75%-1.60% of Si, less than or equal to 0.50% of Al, 20.0%-23.0% of Cr, less than or equal to 0.6% of Mn, less than or equal to 1.0% of Fe, less than or equal to 0.020% of P, less than or equal to 0.015% of S, 0.10%-0.30% of W, 0.20%-0.50% of Co, 0.10%-0.25% of Zr and the balance Ni and inevitable impurities. The nickel-chromium series high-resistance electrothermal alloy is small in expansion coefficient, good in resistance uniformity and long in service life.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

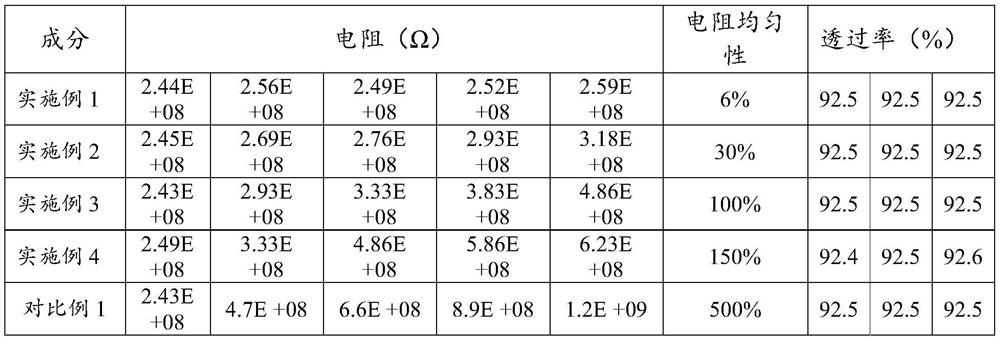

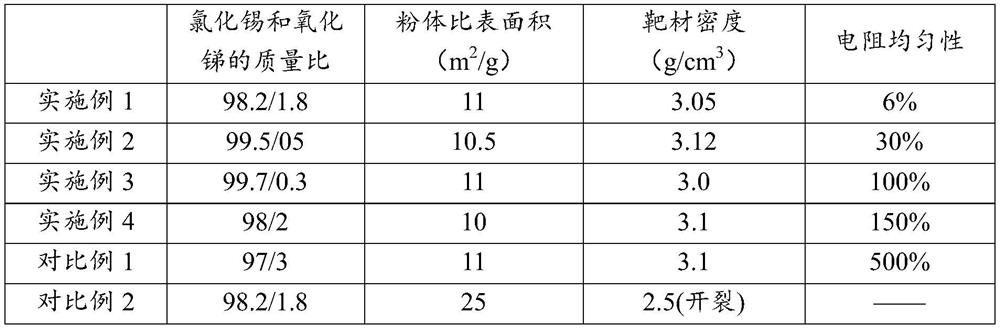

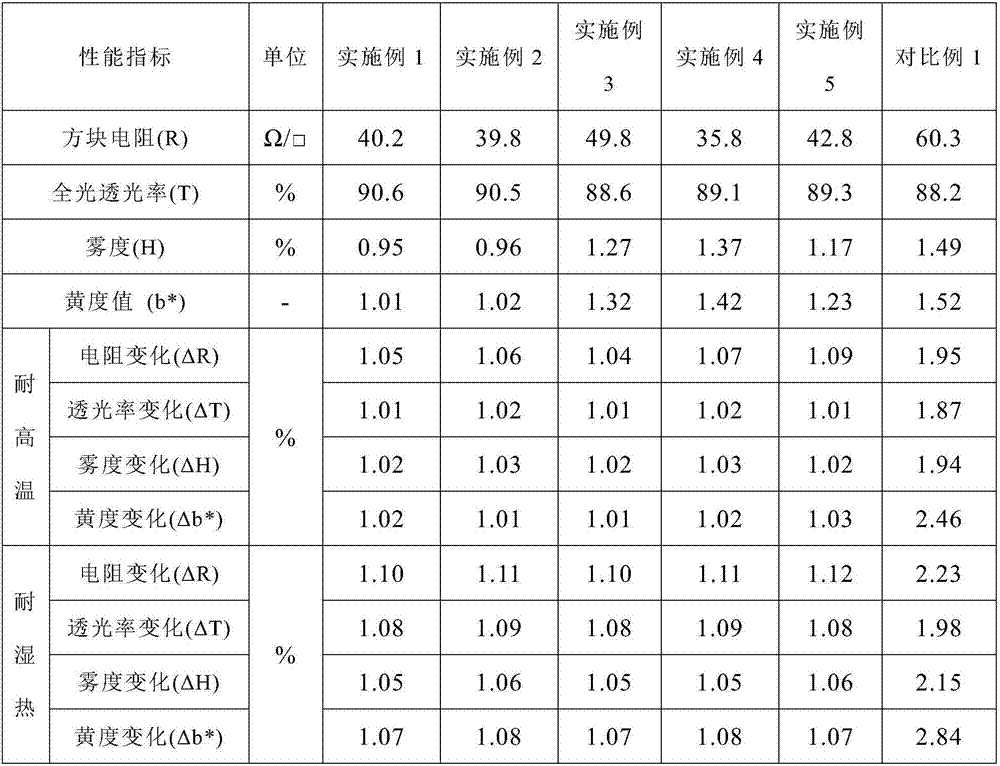

ATO target precursor and preparation method and application thereof

PendingCN113831120AImprove resistance uniformityHigh optical transmittanceVacuum evaporation coatingSputtering coatingPhysical chemistryOptical transmittance

The invention discloses an ATO target precursor and a preparation method and application thereof. The precursor is prepared from the following raw materials: tin oxide and antimony oxide, the mass fraction of the antimony oxide is 0.15%-1.8%; the specific surface area of the ATO target material precursor is between 15m < 2 > / g and 25m < 2 > / g. The ATO target material with excellent resistance uniformity and high optical transmittance is prepared by controlling the doping proportion of antimony oxide.

Owner:长沙壹纳光电材料有限公司

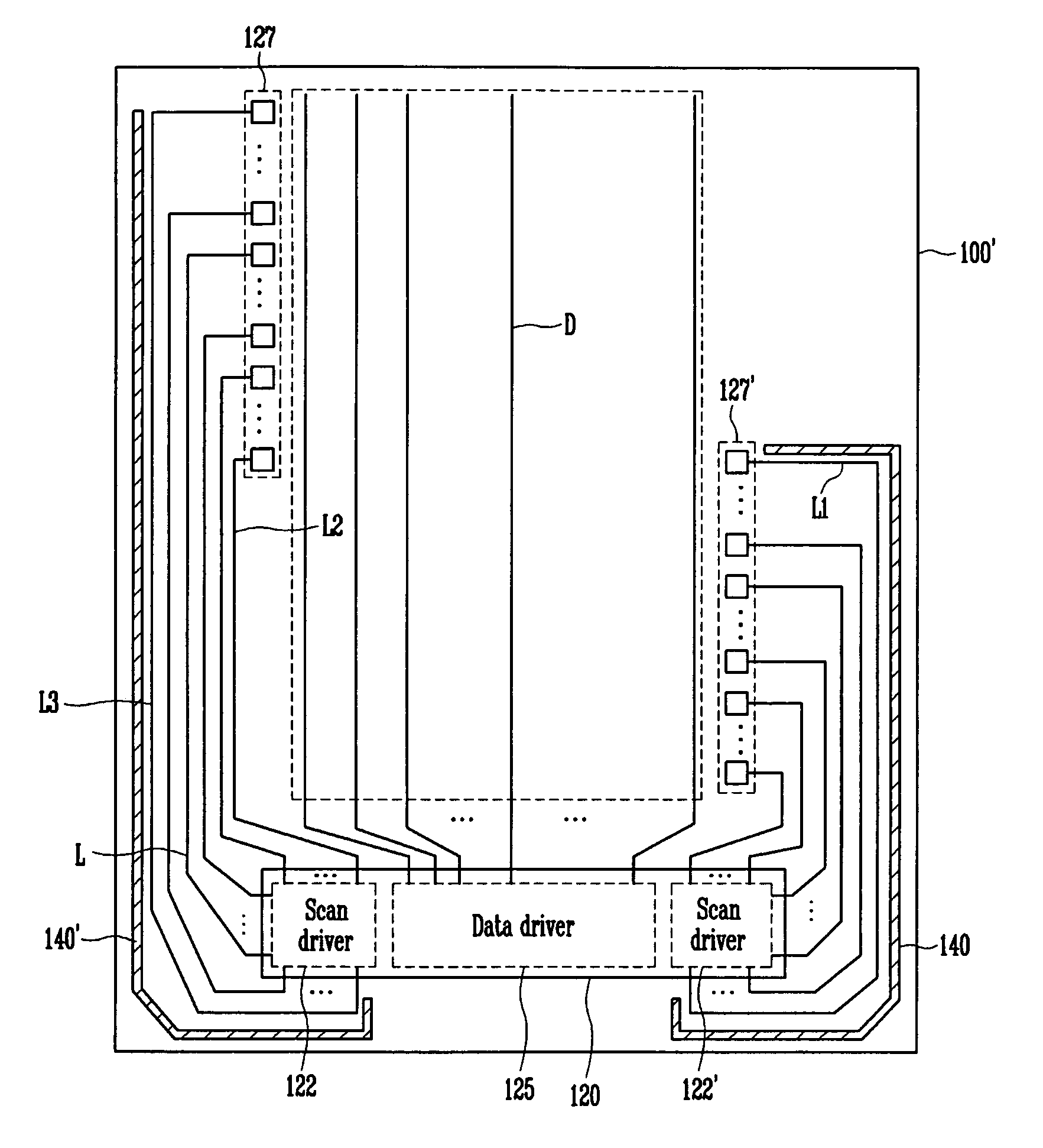

Array substrate and method for manufacturing the same, display apparatus

ActiveUS20150249098A1Reduce resistanceImprove resistance uniformitySemiconductor/solid-state device detailsSolid-state devicesElectricitySignal lines

An array substrate is disclosed. The array substrate comprises a substrate, a plurality of common electrodes formed on the substrate, a plurality of gate signal lines formed above the common electrodes, and a plurality of common electrode signal line units corresponding to the plurality of common electrodes, respectively. The plurality of common electrode signal line units are formed on the corresponding common electrodes, respectively. Each of the common electrode signal line units comprises a first common electrode signal line perpendicular to the gate signal line and a second common electrode signal line parallel to the gate signal line. The first and second common electrode signal lines are made of metal and cross with each other and are electrically connected to each other. Two adjacent common electrode signal line units are electrically connected by a bridge line. The present disclosure also relates to a method for manufacturing the array substrate and a display apparatus.

Owner:BOE TECH GRP CO LTD +1

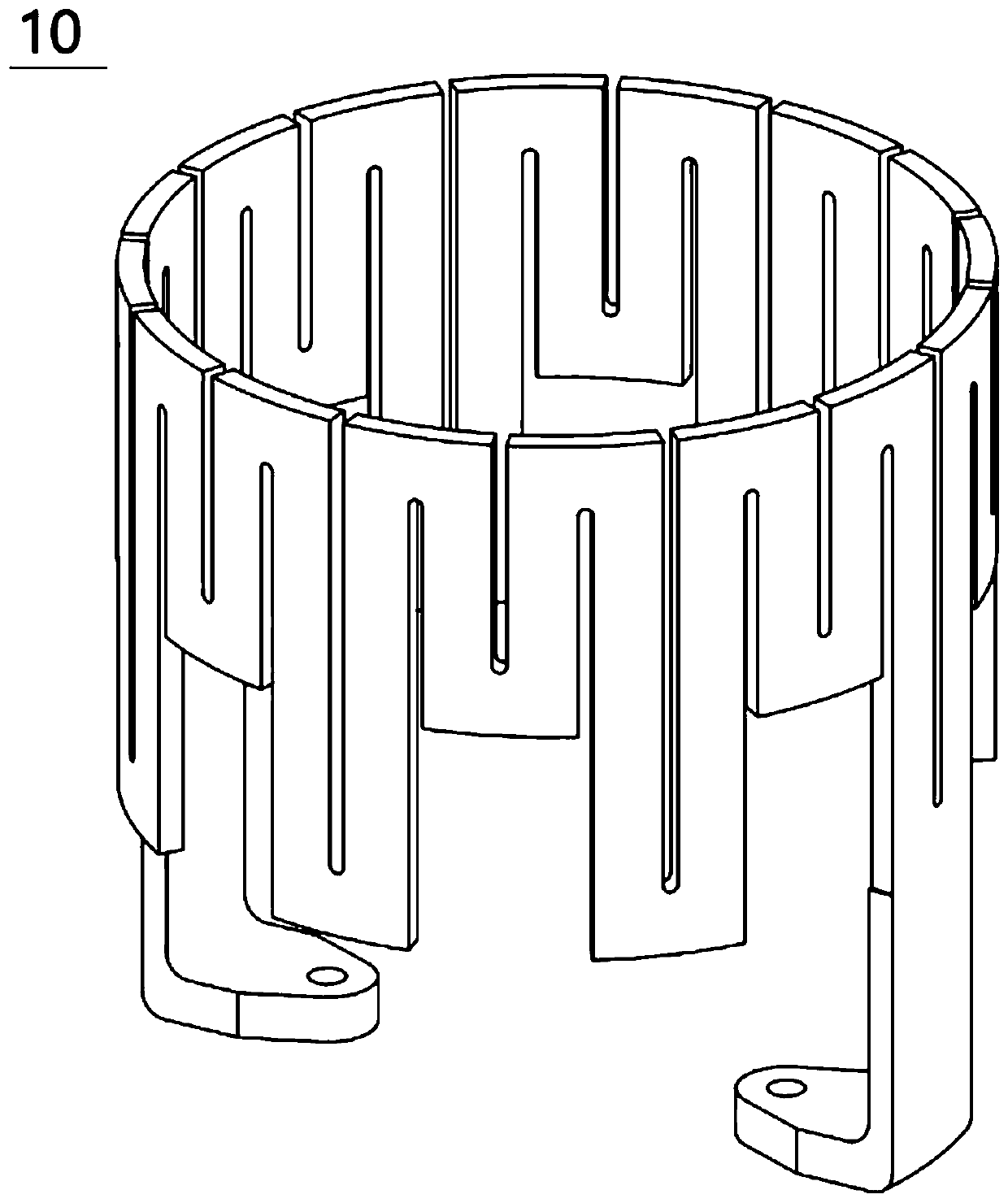

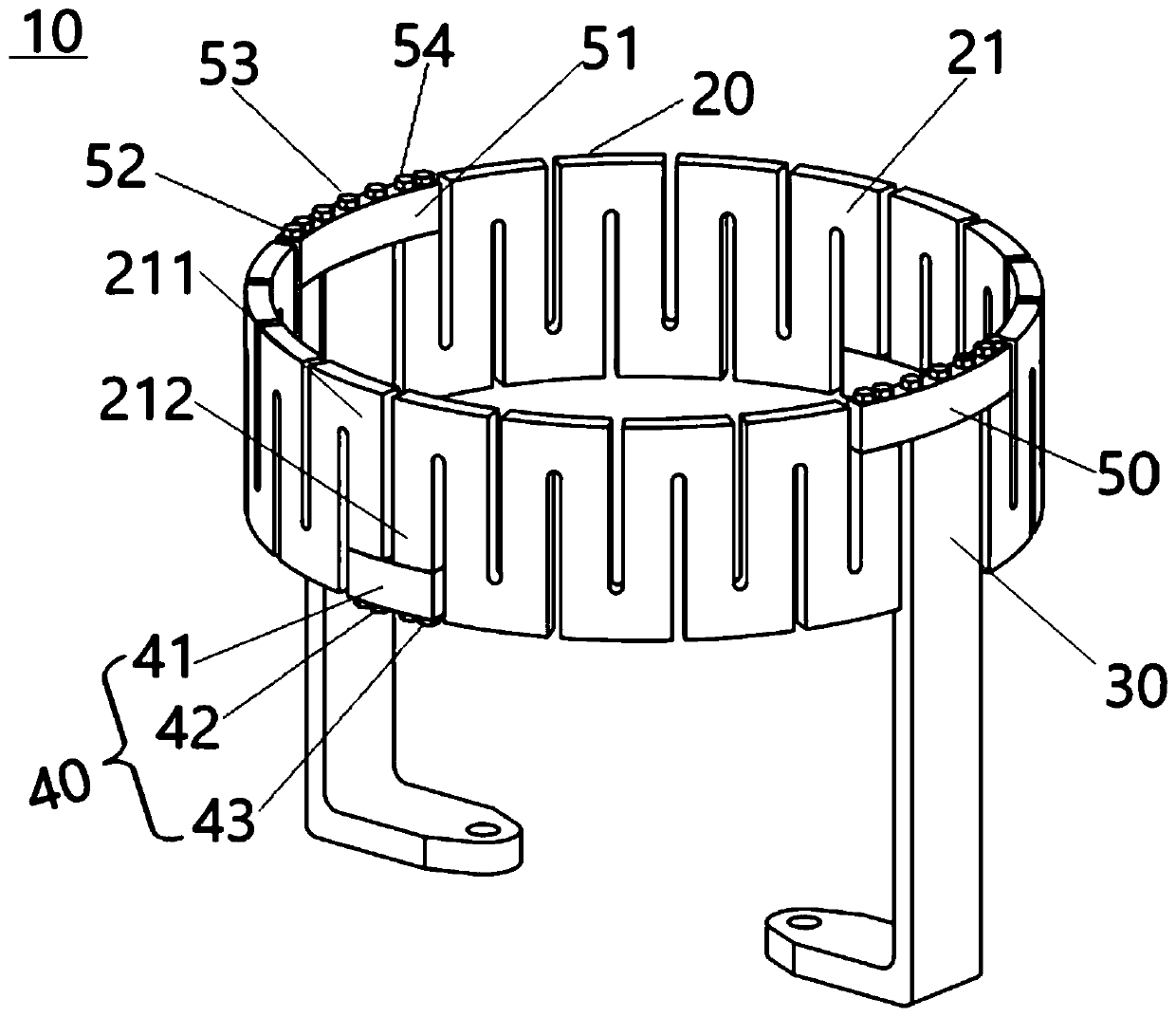

Single crystal furnace heater

InactiveCN111394798ALow costReduce use costAfter-treatment apparatusFurnace heating elementsSingle crystalGraphite

The present invention relates to a single crystal furnace heater, which comprises: a body comprising a plurality of heating parts connected end to end to form a ring, each heating part comprising a plurality of heating plates; heater legs positioned between the two heating parts; first and second connecting pieces, wherein the two adjacent heating parts are connected through the first connecting pieces, and each heater leg is connected with the corresponding two adjacent heating parts through the second connecting piece. According to the single crystal furnace heater, each component can be independently processed, and assembled for use, a problem that a single crystal furnace heater is formed by processing a whole graphite material is avoided, the use of graphite materials is greatly reduced, so that the cost of the single crystal furnace heater is effectively reduced, and after the single crystal furnace heater is used for a period of time, only aged parts need to be replaced, and thewhole single crystal furnace heater does not need to be scrapped, so that the use cost of the single crystal furnace heater is further reduced.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL

Method for preparing transparent conductive film on sodium-calcium based substrate by using magnetron sputtering

InactiveCN104451575ALow resistivityLight in massVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceSputtering

The invention discloses a method for preparing a transparent conductive film on a sodium-calcium-based substrate by using magnetron sputtering. In the invention, through using magnetron sputtering and based on different resistance values in a vacuum chamber, indium tin oxide films with different thicknesses can be prepared through deposition. The prepared indium tin oxide films have characteristics of uniform resistance, low resistivity, high light transmittance, good chemical stability and the like, and have good use value and economic value.

Owner:WUXI HUIMING ELECTRONICS TECH

Silver nanowire-silver complex composite conductive ink and preparation method of transparent conductive film thereof

ActiveCN107345096APrevent agglomeration and sedimentationImprove stabilityInksCoatingsElectrically conductiveTransparent conducting film

The invention discloses silver nanowire-silver complex composite conductive ink which comprises silver nanowire ink and silver complex ink, wherein the silver nanowire ink accounts for 80-95 wt%, and the silver complex ink accounts for 5-20 wt%; the silver nanowire ink comprises a silver nanowire and a dispersing agent, the silver nanowire accounts for 0.5-5 wt%, and the dispersing agent accounts for 95-99.5 wt%; and the silver complex ink comprises a silver complex and a stabilizer, the silver complex accounts for 5-10 wt%, and the stabilizer accounts for 90-95wt%. According to the silver nanowire-silver complex composite conductive ink disclosed by the invention, the preservation period of the composite conductive ink can be prolonged, industrialized production is easily realized, the conductivity and uniformity of the formed film are improved, the speed of separating out the silver nanowire in the silver nanowire ink can be effectively reduced, and the silver nanowire is prevented from being agglomerated and settled; and meanwhile, the resistance uniformity of the silver nanowire after film formation can be increased.

Owner:CHINA LUCKY FILM CORP +1

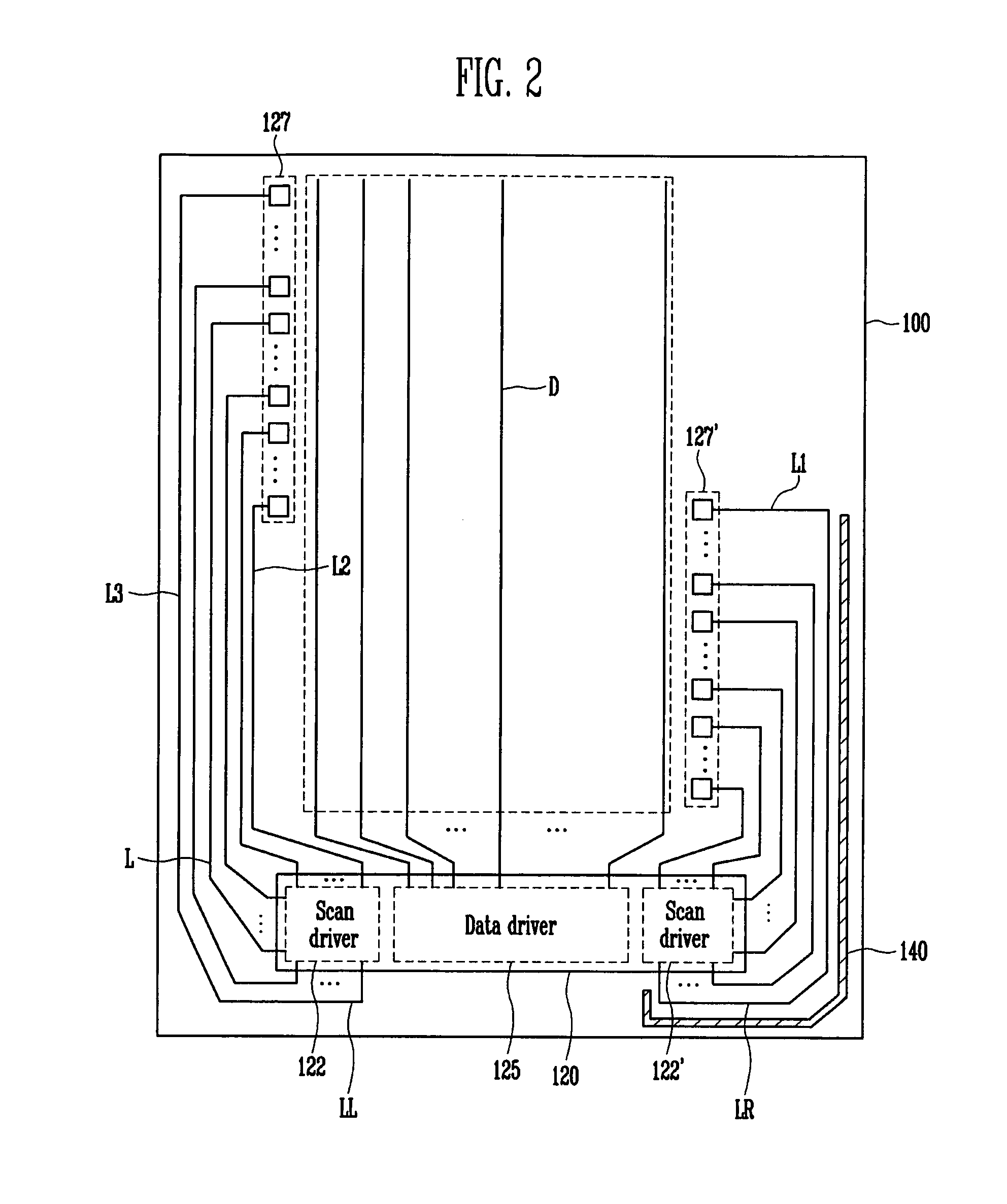

Liquid crystal display device having particular dummy pattern

A liquid crystal display (LCD) device includes lower and upper substrates attached to each other, a plurality of data lines on the lower substrate, a plurality of lead lines on the lower substrate, the lead lines being positioned in a dummy region of the lower substrate, a plurality of scan lines on the upper substrate, the scan lines being connected to respective lead lines and being positioned to intersect with the data lines, and at least one dummy pattern on the lower substrate, the dummy pattern being positioned in the dummy region between an edge of the lower substrate and a corresponding outermost lead line of the plurality of lead lines.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

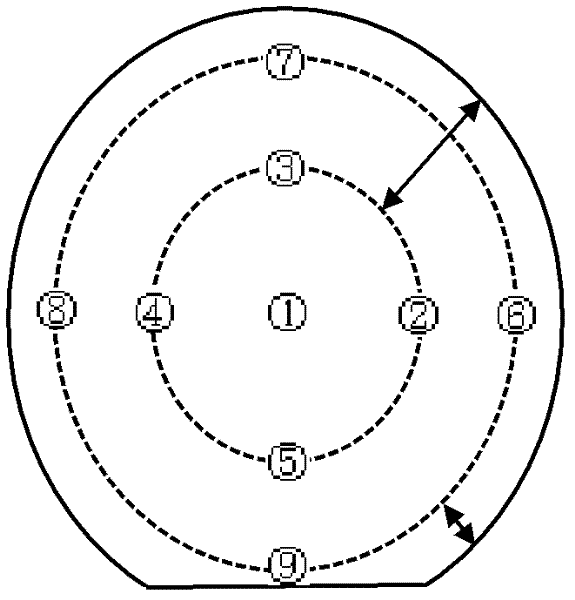

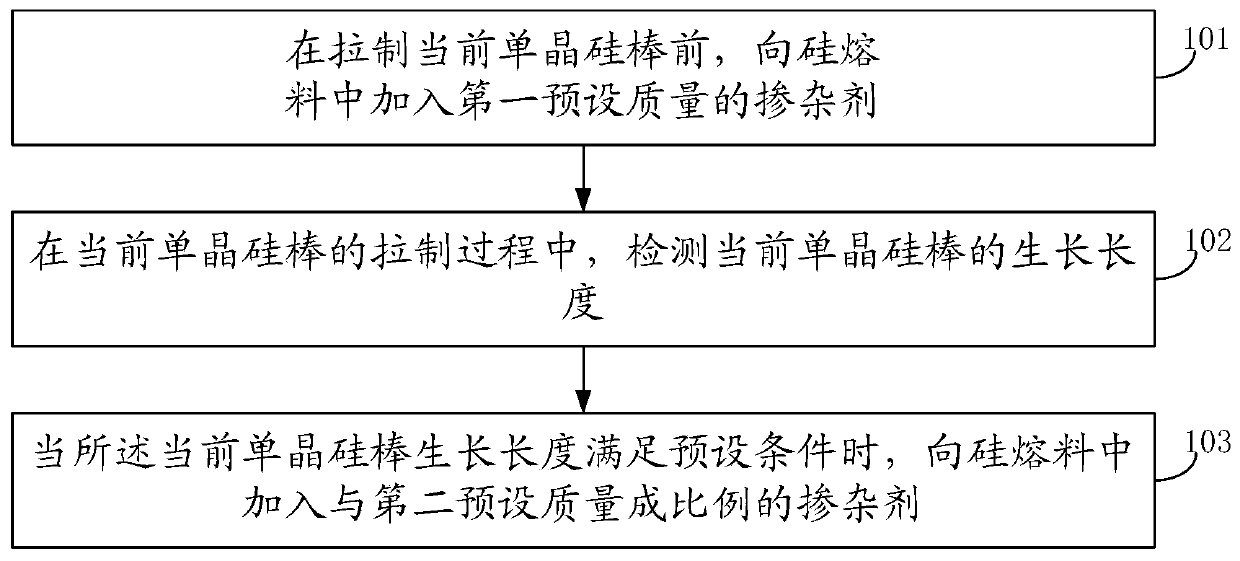

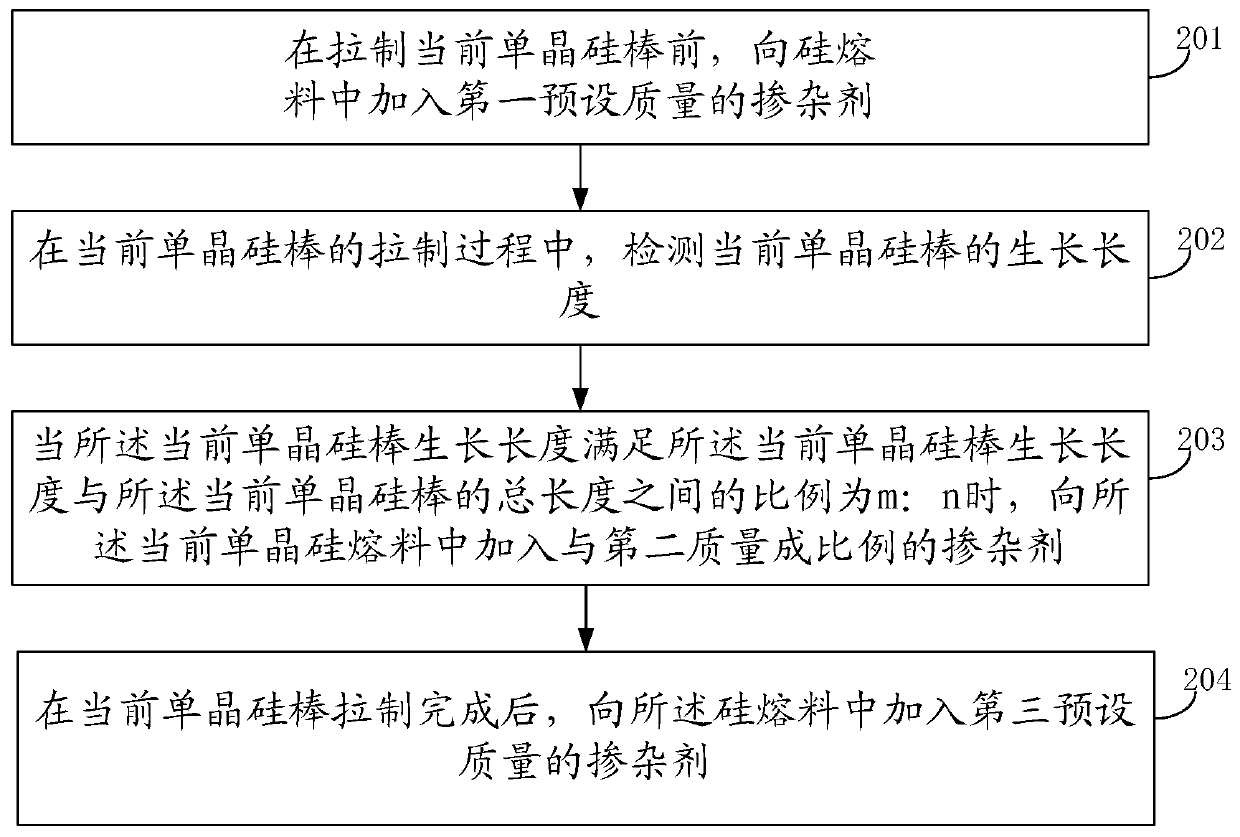

Doping method, single crystal device and single crystal furnace

InactiveCN110528066AImprove resistance uniformityImprove qualityPolycrystalline material growthBy pulling from meltElectrical resistance and conductanceDopant

The invention provides a doping method, a single crystal device and a single crystal furnace. The method comprises the following steps: adding a dopant with a first preset mass into a silicon melt before a current monocrystalline silicon rod is drawn; detecting the growth length of the current monocrystalline silicon rod in a drawing process of the current monocrystalline silicon rod; and adding adopant proportional to a second preset mass into the silicon melt when the growth length of the current monocrystalline silicon rod meets a preset condition. According to the invention, addition of the dopant and drawing of the current monocrystalline silicon rod can be carried out synchronously; in the drawing process of the monocrystalline silicon, the dopant is added into the silicon melt whenthe growth length of the current monocrystalline silicon rod meets the preset condition; and due to centripetal force generated by rotation of a crucible, the dopant can be uniformly distributed on the surface of the silicon melt, so that uniformity of the dopant in each part of a drawn current monocrystalline silicon rod is ensured, resistance uniformity of the prepared current monocrystalline silicon rod is improved, and then the actual yield of the current monocrystalline silicon rod is improved.

Owner:NINGXIA LONGI SILICON MATERIALS

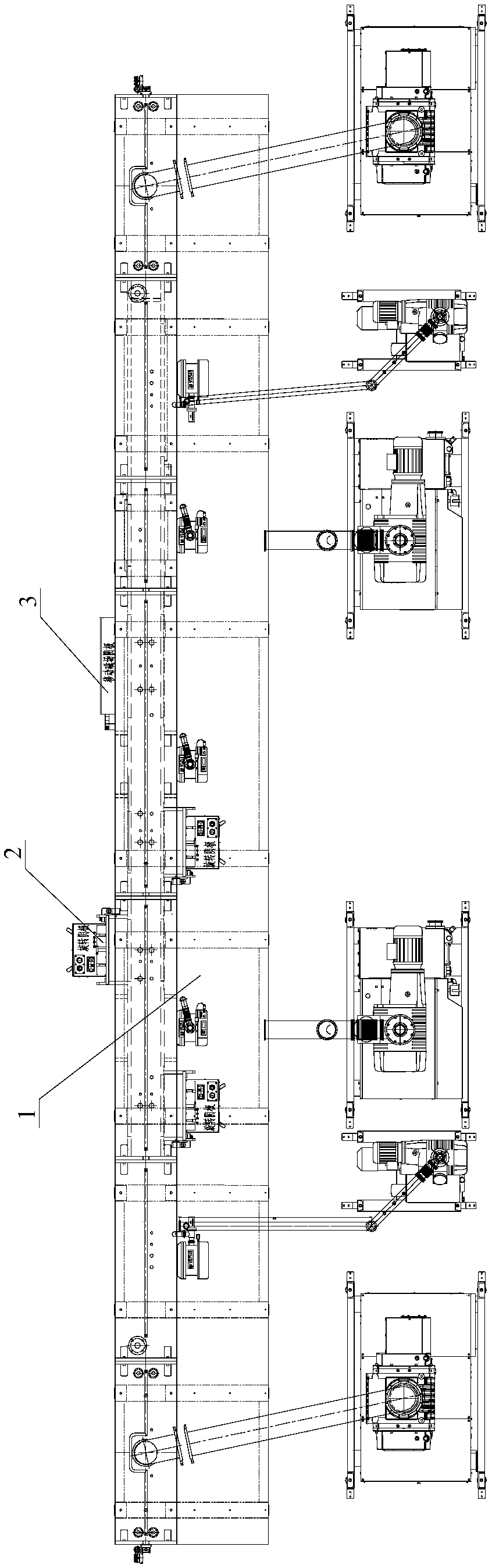

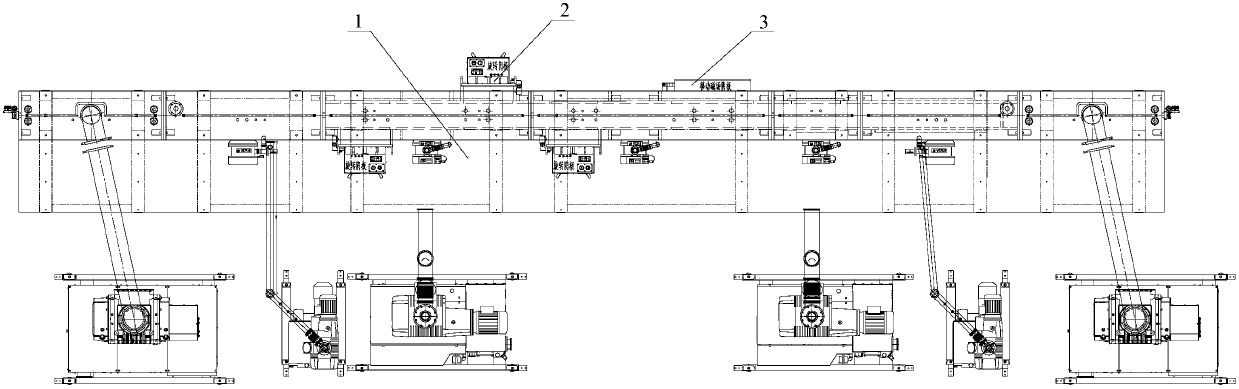

Glass thinning and coating method and equipment

InactiveCN109957768AGood coating effectGood resistance uniformityVacuum evaporation coatingSputtering coatingEngineeringVacuum pumping

The invention discloses a glass thinning and coating method, which comprises the following steps of: fixing a substrate on a substrate frame, feeding the substrate frame into an inlet chamber, sealing, and performing low-vacuum pumping; feeding the substrate frame into an inlet buffer chamber, and carrying out high-vacuum pumping; then feeding the substrate frame into an inlet conveying chamber, preheating the substrate under high vacuum; sending the substrate frame into a process chamber, carrying out coating treatment, heating the substrate during coating, and keeping the temperature of thesubstrate at 150-250 DEG C; and sending the coated substrate out. The invention further discloses glass thinning and coating equipment which sequentially comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a process chamber, an outlet conveying chamber, an outlet buffer chamber and an outlet chamber, the equipment further comprises a vacuum pump, the vacuum pump is a molecular pump, and the molecular pump is mounted on a door plate; and the inlet buffer chamber, the inlet conveying chamber, the process chamber, the outlet conveying chamber and the outlet buffer chamber are all provided with heating devices.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com