Nickel-chromium series high-resistance electrothermal alloy and preparation method thereof

An electrothermal alloy, high-resistance technology, used in metal rolling, metal rolling, heat treatment equipment, etc., can solve the problems of poor thermal physical properties of materials, unsatisfactory mechanical properties, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

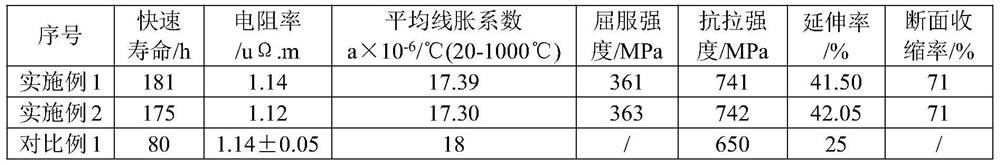

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of the above-mentioned nickel-chromium series high-resistance electrothermal alloy, comprising the following steps:

[0039] a. Use the vacuum induction melting process to smelt the raw materials of nickel-chromium series high-resistance electrothermal alloys. The vacuum degree of smelting is less than 1.0Pa. Melt at 1500-1530°C for 30-50min, and cast into electrode rods with a diameter of 200-240mm;

[0040] b. The electrode rod is smelted by electroslag remelting process, the smelting current is 6000-8000A, the smelting voltage is 50-60V, and the electroslag ingot with a diameter of 320-360mm is obtained;

[0041] c. Heat the electroslag ingot to 1170°C~1190°C, keep it warm for 3~4h, start forging temperature ≥1080°C, final forging temperature ≥900°C, forge a billet of 140×140~150×150mm, and air cool ;

[0042] d. Carry out continuous rolling of the billet. During the continuous rolling process, the steel bille...

Embodiment 1

[0048] The chemical composition of the nickel-chromium series high-resistance electric heating alloy in this embodiment is calculated by mass percentage: C 0.025%, Si 1.30%, Mn 0.10%, P 0.005%, S 0.001%, Al 0.45%, Fe 0.32%, Cr 20.7 %, W 0.13%, Co 0.48%, Zr 0.11%, and the balance is Ni and unavoidable impurities.

[0049] The preparation method of the nickel-chromium series high-resistance electrothermal alloy of this embodiment:

[0050] a. Dosing according to the weight percentage of the alloy composition in Example 1, put the raw materials into a vacuum induction furnace for smelting, the vacuum degree is less than 1.0Pa, smelting at 1510°C for 45min, and pouring into an electrode rod with a diameter of 240mm;

[0051] b. The electrode rod is smelted by the electroslag remelting process, the smelting current is 6000-8000A, the smelting voltage is 50-60V, and an electroslag ingot with a diameter of 360mm is obtained;

[0052] c. Heat the electroslag ingot to 1180°C, keep it ...

Embodiment 2

[0057] The chemical composition of the nickel-chromium series high-resistance electric heating alloy in this embodiment is calculated by mass percentage: C 0.020%, Si 1.25%, Mn 0.010%, P 0.002%, S 0.001%, Al 0.42%, Fe 0.34%, Cr 20.5% %, W 0.20%, Co 0.31%, Zr 0.23%, and the balance is Ni and unavoidable impurities.

[0058] The preparation method of the nickel-chromium series high-resistance electrothermal alloy of this embodiment:

[0059] a. Dosing according to the weight percentage of the alloy composition in Example 2, put the raw materials into a vacuum induction furnace for melting, the vacuum degree <1.0Pa, melt at 1530° C. for 30 minutes, and pour into an electrode rod with a diameter of 240 mm;

[0060] b. The electrode rod is smelted by the electroslag remelting process, the smelting current is 6000-8000A, the smelting voltage is 50-60V, and the electroslag ingot with a diameter of Φ360mm is obtained;

[0061] c. Heat the electroslag ingot to 1190°C, keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com