Conductive composition exhibiting PTC behavior and over-current protection device using the same

A conductive composite material and positive temperature coefficient technology, which is applied in the direction of resistors with positive temperature coefficient, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve the problem that resistance reproducibility is difficult to control and cannot be effectively reduced Resistance value, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The formulation ingredients used in Example 1 are shown in Table 2. The feed temperature of the batch mixer (Hakke-600) is set at 160°C, and the feed time is 2 minutes. The feed program is to add a certain amount of high-density polyethylene first, stir for a few seconds, and then add conductive filler (nickel powder and conductive carbon black). The rotational speed of the mixer rotation was 40 rpm. After 3 minutes, the rotating speed was increased to 70 rpm, and the kneading was continued for 7 minutes before feeding to form a conductive composite material with positive temperature coefficient characteristics.

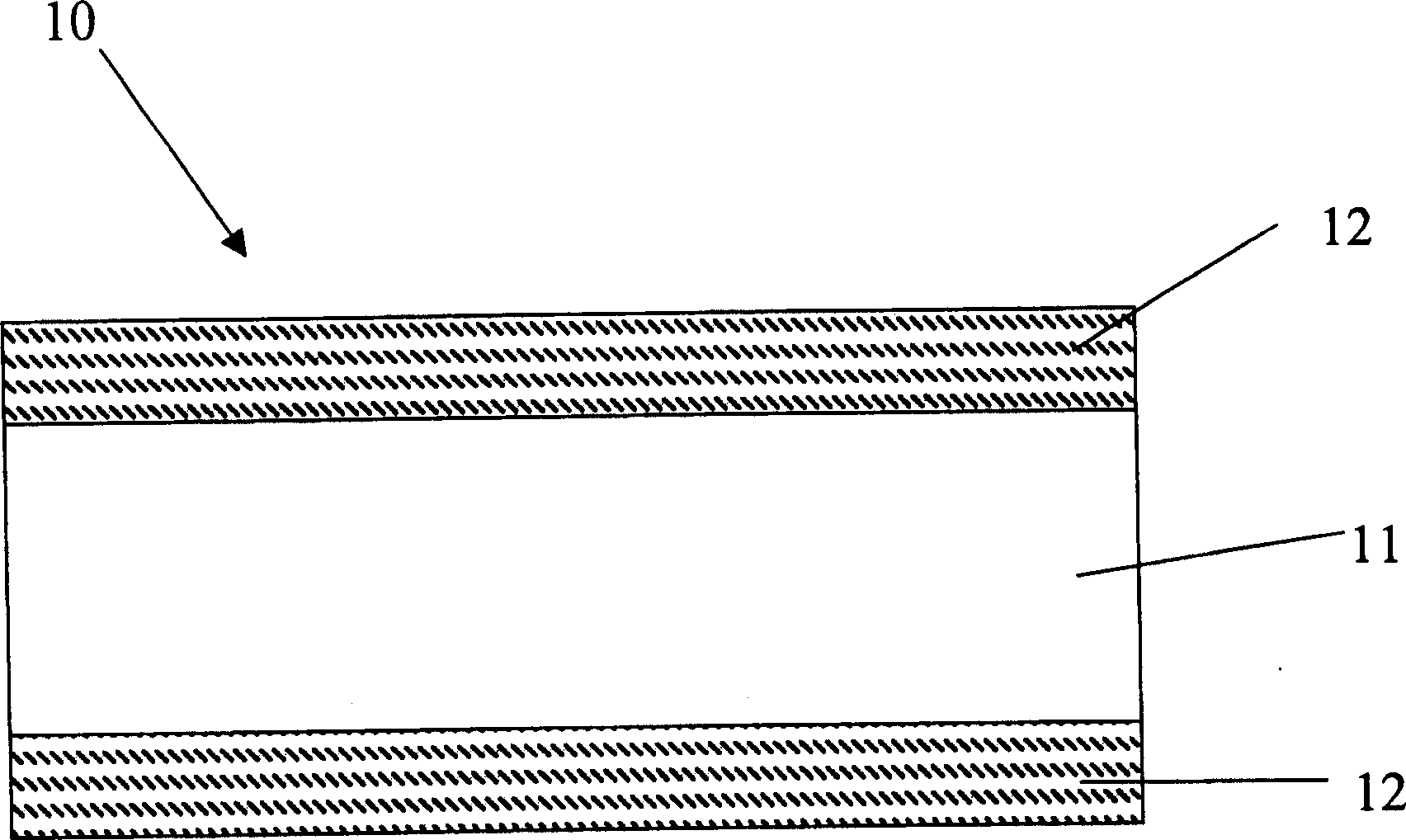

[0018] Put the above-mentioned conductive composite material into a mold with a steel plate as the outer layer and a middle thickness of 0.25mm in a symmetrical manner up and down. Put a layer of Teflon release cloth on the top and bottom of the mold, pre-press for 3 minutes, and the pre-press operating pressure is 50kg / cm 2 , the temperature is 180°C. Pr...

Embodiment 2

[0020] The steps for preparing the PTC element are the same as in Example 1, but the volume percentage of high-density polyethylene is reduced from 57 to 54. In addition, a coupling agent (Capow-12) is added between the step of adding high-density polyethylene and the step of adding conductive filler. Stir for several seconds before and after adding the coupling agent. The volume percentage of the coupling agent is 3. The formulation of the conductive composite material of this embodiment and the electrical characteristics of the PTC element are shown in Table 2.

Embodiment 3

[0022] The steps for preparing the PTC element are the same as in Example 1, but the volume percentage of high-density polyethylene is reduced from 57 to 47. In addition, while adding high-density polyethylene, add carboxyl resin (MB-100D), the volume percentage of the carboxyl resin is 10. The formulation of the conductive composite material of this embodiment and the electrical characteristics of the PTC element are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com