Doping method, single crystal device and single crystal furnace

A single crystal furnace and single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems that the resistance uniformity of single crystal silicon rods cannot meet the standard and affect the quality of single crystal silicon rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

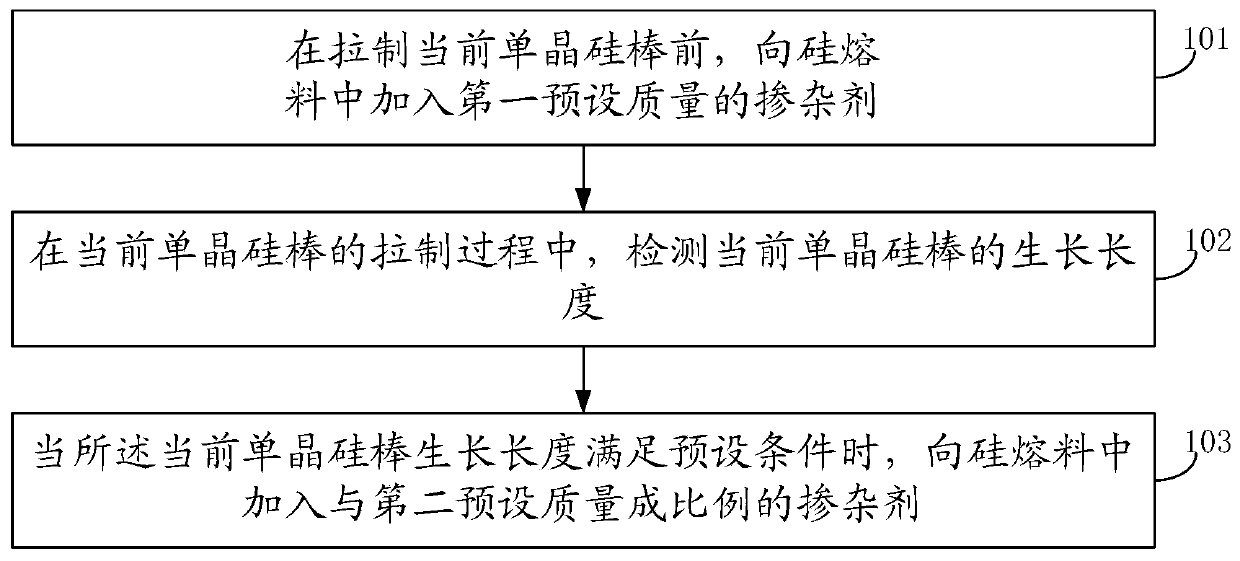

[0046] refer to figure 1 , figure 1 It shows a flow chart of the steps of a doping method according to Embodiment 1 of the present invention, the method comprising:

[0047] Step 101 , before pulling the current single crystal silicon rod, adding a first preset mass of dopant to the silicon melt.

[0048] In the embodiment of the present invention, before pulling the current single crystal silicon rod, a dopant of a first preset quality is added to the silicon melt, and adding the dopant of the first preset quality to the silicon melt is In order to ensure that the initially generated part of the current single crystal silicon rod is doped with dopants when the current single crystal silicon rod is drawn, and because the crucible rotates when the current single crystal silicon rod is drawn, a centripetal force is generated, so that the doped The dopant is evenly distributed on the surface of the silicon melt, so that the dopant distribution in the current monocrystalline sil...

Embodiment 2

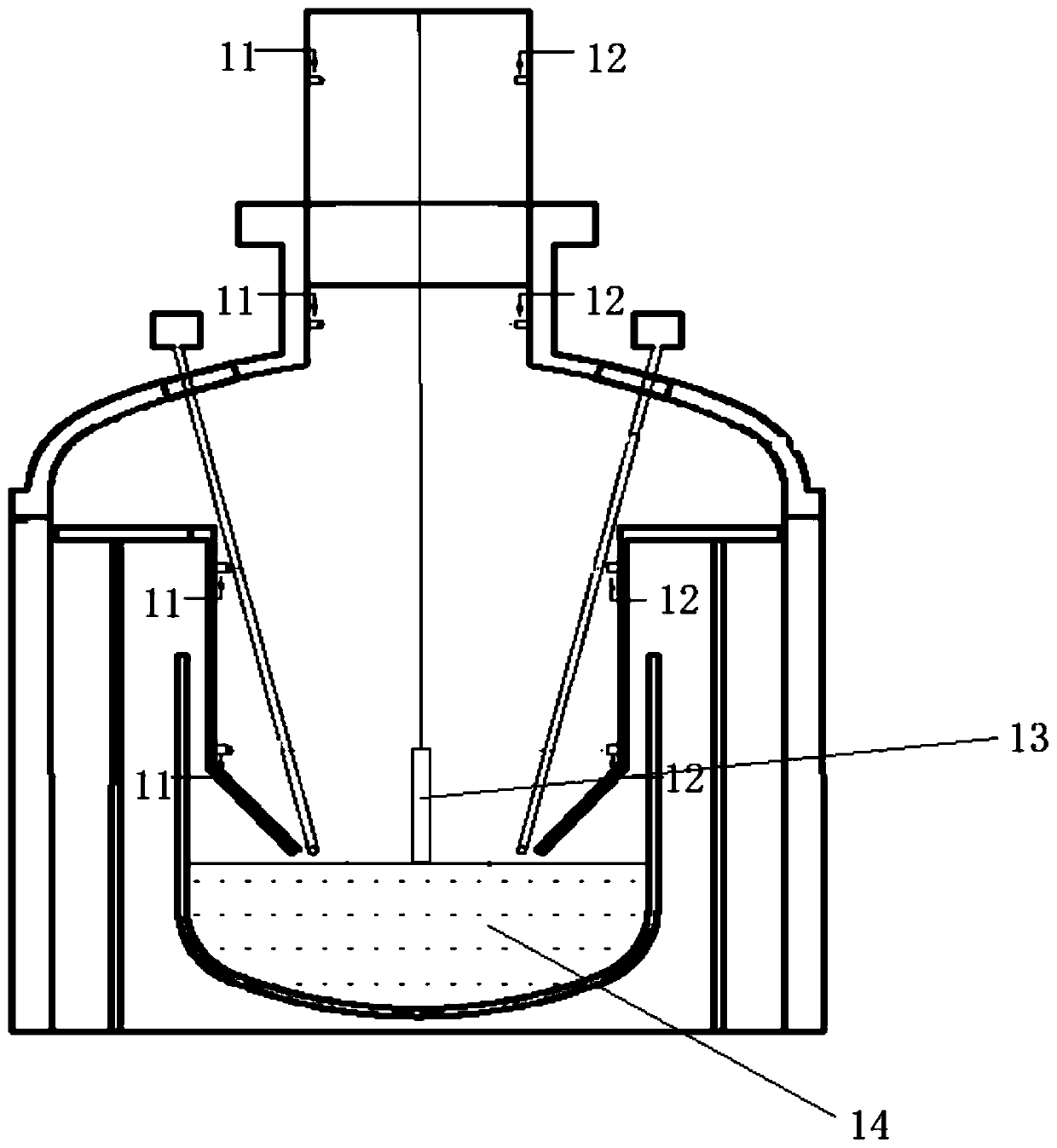

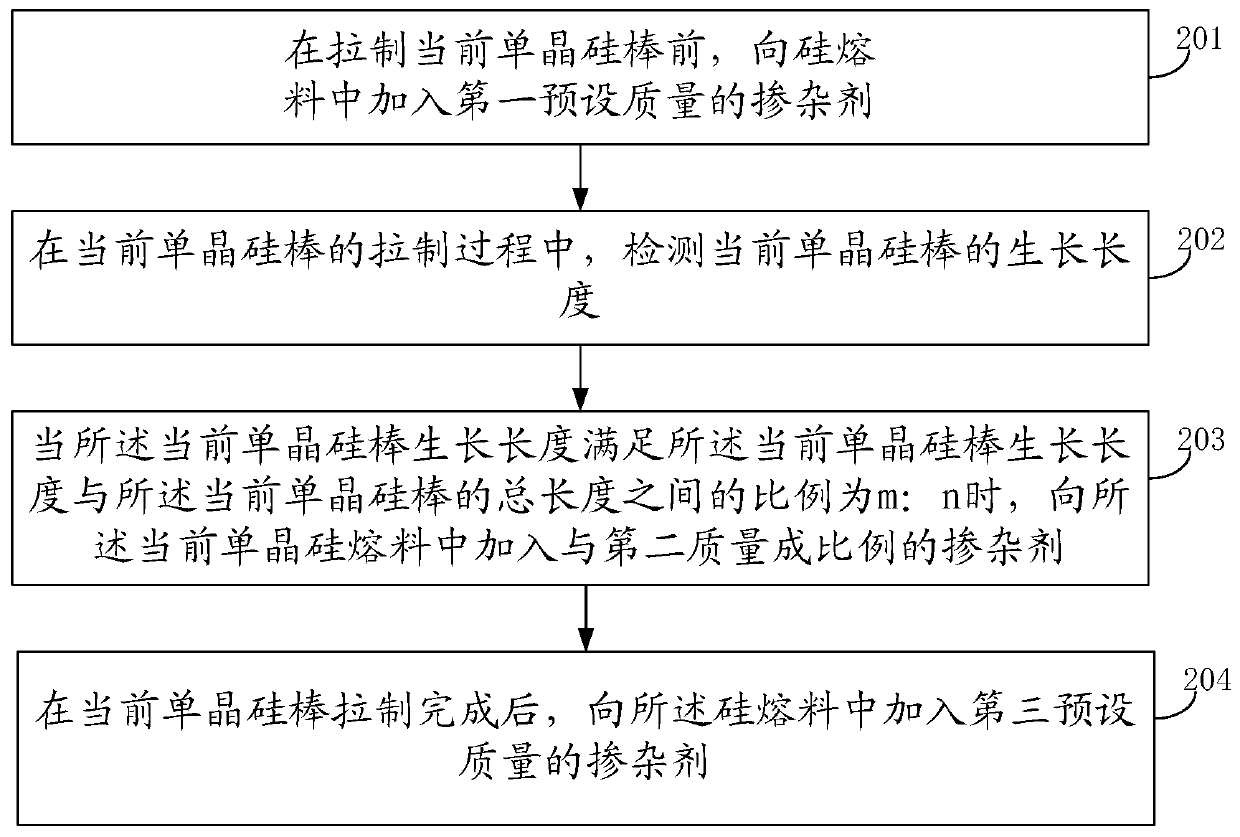

[0063] refer to image 3 , image 3 It shows a flow chart of steps of a doping method in Embodiment 2 of the present invention, the method includes: the method is applied to Figure 4 shown in the single crystal furnace, refer to Figure 4 , the single crystal furnace includes a dopant 10, a photosensitive sensor and a controller (not shown in the figure); the dopant 10 is arranged in the single crystal furnace through an opening 15 on the single crystal furnace, and the photosensitive sensor It includes a photosensitive sensor transmitting end 11 and a photosensitive sensor receiving end 12 . The photosensitive sensor is connected with the controller, and the controller is connected with the dopant 10 . Step 201, before pulling the current single crystal silicon rod, adding a dopant of a first preset quality into the silicon melt.

[0064] In the embodiment of the present invention, the steps are the same as step 101 in the first embodiment, and will not be repeated here....

Embodiment 3

[0095] refer to Figure 5 , shows that the embodiment of the present invention discloses a single crystal device 30, and the single crystal device 30 includes: a first control module 301, a detection module 302 and a second control module 303;

[0096] The first control module 301 is used to add a dopant of a first preset quality to the silicon melt before pulling the current single crystal silicon rod;

[0097] The detection module 302 is used to detect the growth length of the current single crystal silicon rod during the current pulling process of the single crystal silicon rod;

[0098] The second control module 303 is configured to add a dopant proportional to a second preset mass to the molten silicon when the growth length of the current single crystal silicon rod satisfies a preset condition.

[0099] Optionally, the preset condition includes: the ratio between the growth length of the current single crystal silicon rod and the preset total length of the current singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com