ATO target precursor and preparation method and application thereof

A technology of precursors and targets, which is applied in the field of ATO target precursors and its preparation, can solve the problems of obvious difference in electric field strength, influence on liquid crystal deflection, and inability to completely offset them, and achieve excellent resistance uniformity and high optical transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

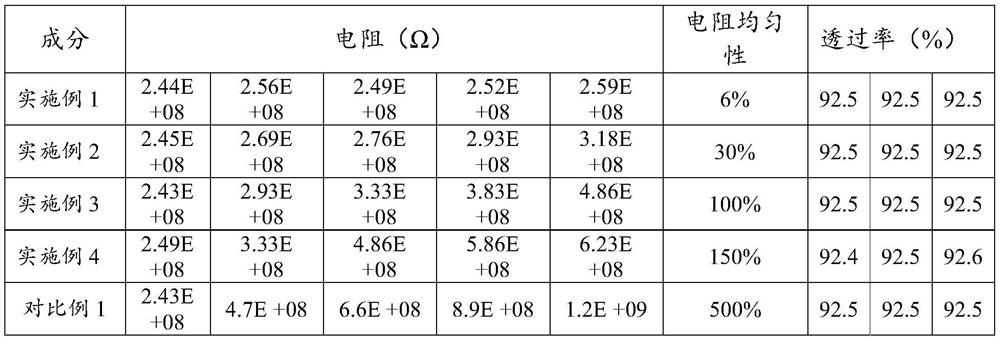

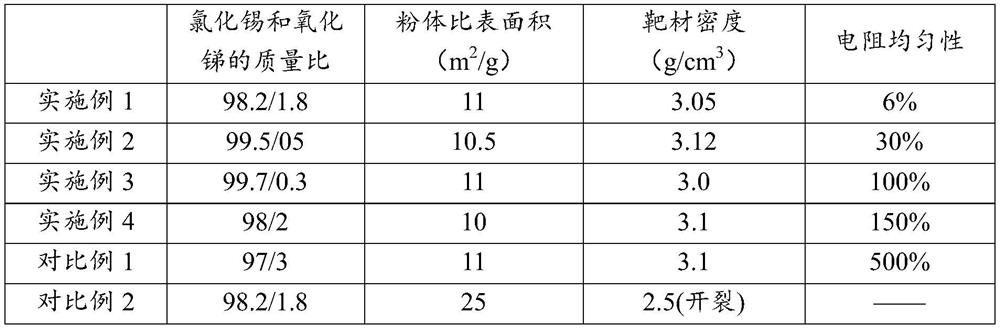

Embodiment 1

[0052] This embodiment is a method for preparing an ATO target, comprising the following steps:

[0053] S1. Prepare powder with tin chloride and antimony oxide at a weight ratio of 98.2:1.8, put the powder into a ball mill for ball milling for 1 hour, and filter and dry the milled slurry at a drying temperature of 120°C. The time is 10h, and the BET is 10m 2 / g of ATO target precursor;

[0054] S2. ATO powder is obtained after spraying and granulating the ATO target precursor, and the D50 is 10 μm.

[0055] S3. The ATO powder is molded under a pressure of 0.4 MPa, and then cold isostatic pressing (10 min) is performed at a pressure of 350 MPa to obtain a blank target material.

[0056] S4. Degrease the blank target at 500°C, and sinter at 1200°C after degreasing to obtain an ATO target (the mass ratio of tin oxide to antimony oxide in the target is 98.2:1.8); where, the degreasing temperature The heating rate is 1°C / min, and it is kept for 5 hours after heating up to 500°C...

Embodiment 2

[0060] This embodiment is a method for preparing an ATO target (adjusting the mass ratio of tin chloride and antimony oxide to 99.5:0.5), including the following steps:

[0061] S1. Prepare powder with tin chloride and antimony oxide at a weight ratio of 99.5:0.5, put the powder into a ball mill for ball milling for 1 hour, and filter and dry the milled slurry at a drying temperature of 120°C. The time is 10h, and the BET is 11m 2 / g of ATO target precursor;

[0062] S2. ATO powder is obtained after spraying and granulating the ATO target precursor, and the D50 is 10 μm.

[0063] S3. The ATO powder is molded under a pressure of 0.4 MPa, and then cold isostatic pressing (10 min) is performed at a pressure of 350 MPa to obtain a blank target material.

[0064] S4. Degrease the rough target at 500°C, and sinter at 1200°C after degreasing to obtain an ATO target (the mass ratio of tin oxide to antimony oxide in the target is 99.5:0.5); where, the degreasing temperature The heat...

Embodiment 3

[0068] This embodiment is a method for preparing an ATO target (adjusting the mass ratio of tin chloride and antimony oxide to 99.7:0.3), including the following steps:

[0069] S1. Prepare powder with tin chloride and antimony oxide at a weight ratio of 99.7:0.3, put the powder into a ball mill for ball milling for 1 hour, and filter and dry the milled slurry at a drying temperature of 120°C. The time is 10h, and the BET is 10.5m 2 / g of ATO target precursor;

[0070] S2. ATO powder is obtained after spraying and granulating the ATO target precursor, and the D50 is 10 μm.

[0071] S3. The ATO powder is molded under a pressure of 0.4 MPa, and then cold isostatic pressing (10 min) is performed at a pressure of 350 MPa to obtain a blank target material.

[0072] S4. Degrease the blank target at 500°C, and sinter at 1200°C after degreasing to obtain an ATO target (the mass ratio of tin oxide to antimony oxide in the target is 99.7:0.3); where, the degreasing temperature The he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com