Capacitance touch screen and manufacture method thereof

A technology of capacitive touch screen and manufacturing method, which is applied in the direction of electrical digital data processing, ion implantation plating, coating, etc., can solve the problems of uneven and fine wire lines, small touch viewing area of touch screen, and poor resistance uniformity, etc. Achieve the effect of fine and uniform wire lines, good resistance uniformity, and reduce bad air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solution of the present invention clearer, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0023] Embodiment of the manufacturing method of the capacitive touch screen:

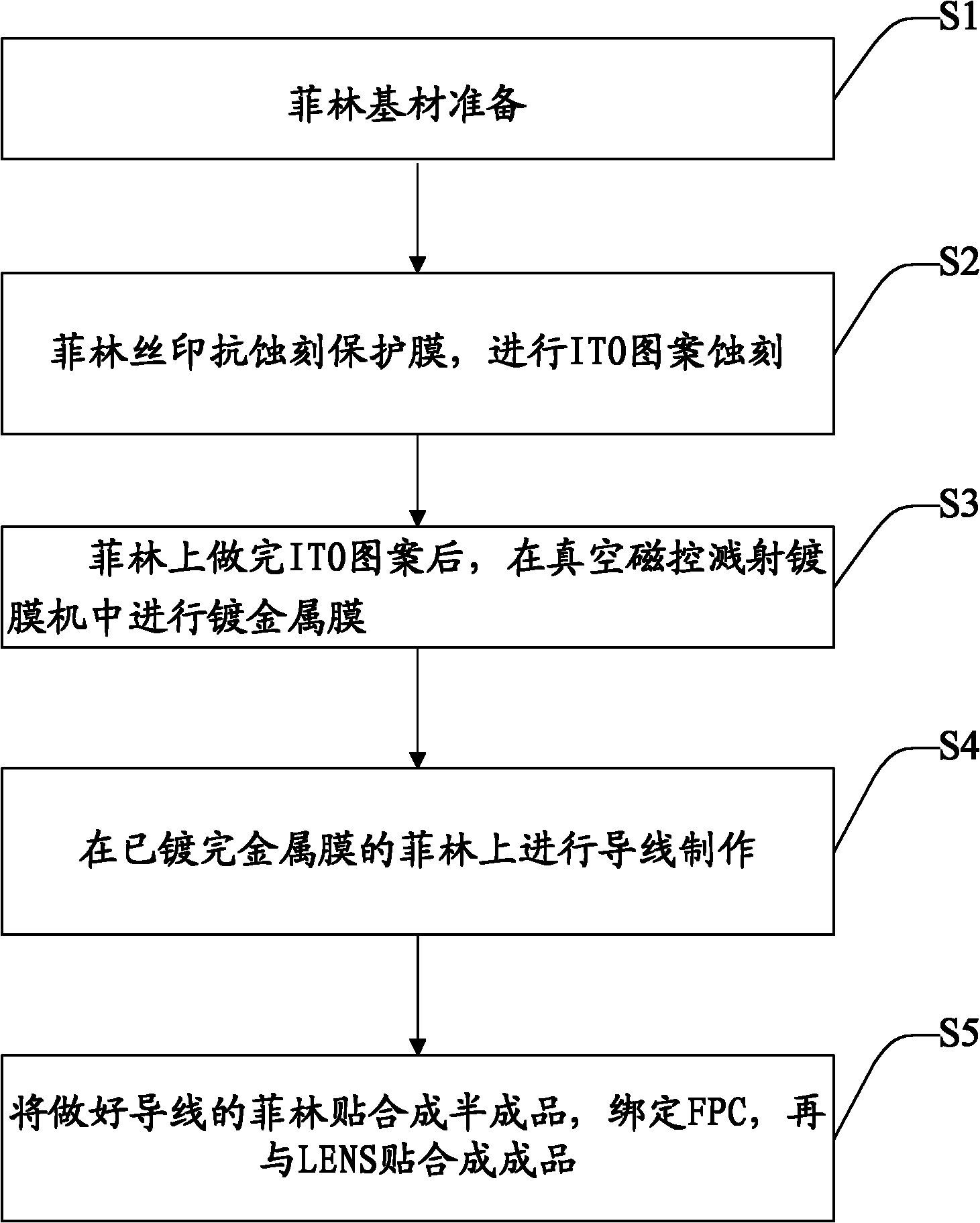

[0024] see image 3 , the manufacture method of capacitive touch screen of the present invention, comprises the steps:

[0025] S1. Film substrate preparation;

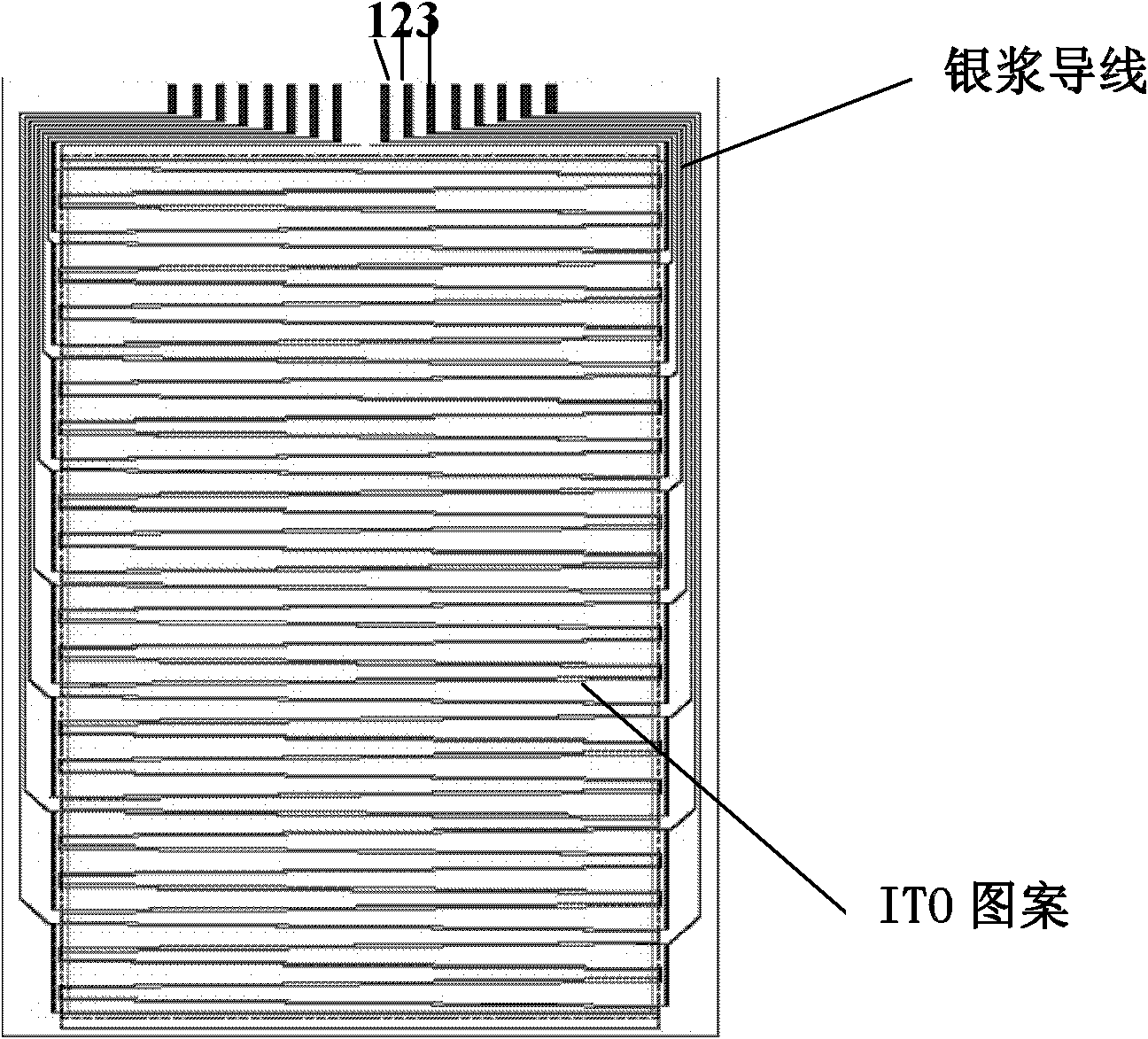

[0026] S2, film silkscreen anti-etching protective film, for ITO pattern etching;

[0027] S3. After the ITO pattern is finished on the film, metallization is performed in a vacuum magnetron sputtering coating machine;

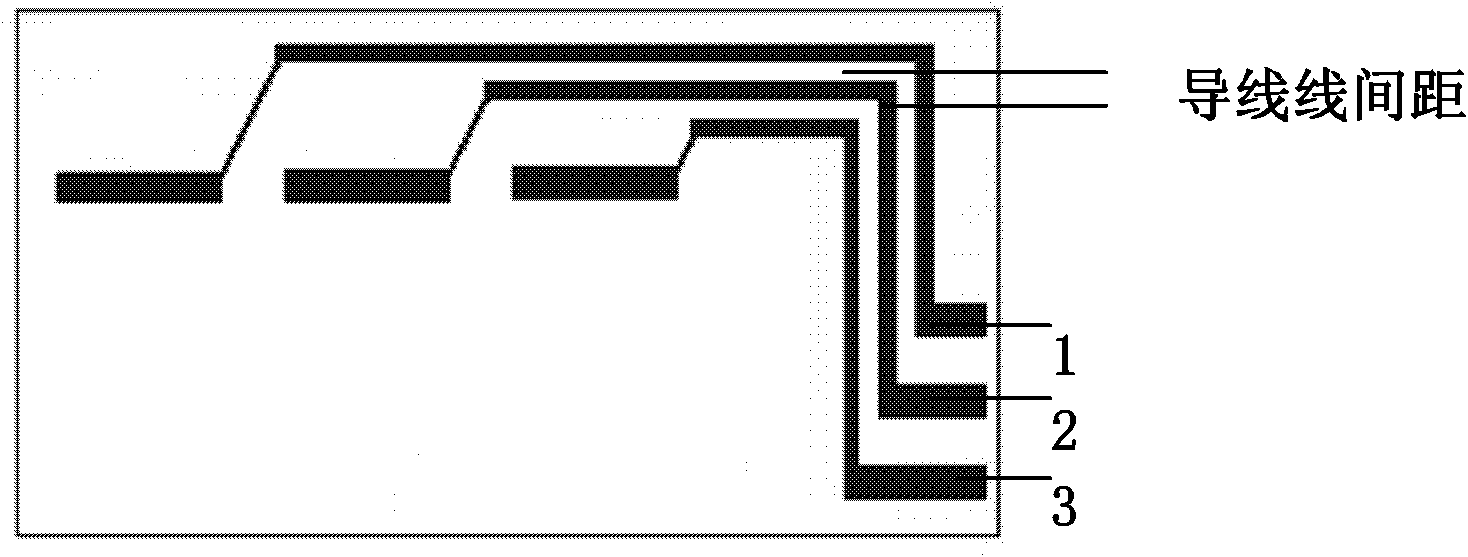

[0028] S4. Carry out wire production on the metal-plated film, that is: form the metal film that has been plated into a wire;

[0029] S5. Paste the wire-finished film into a semi-finished product, bind FPC, and then paste it with LENS to form a finished product.

[0030] Wherein, the film thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com