Programmable logic control device for automobile transmission case with manual gearshift

A technology of programming logic control and gear shift control, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve the problem of damage to mechanical devices such as gearbox gears, and the labor intensity of the driver's hands. Incorrect shifting and other problems, to achieve the effect of low design and manufacturing costs, excellent anti-interference performance, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

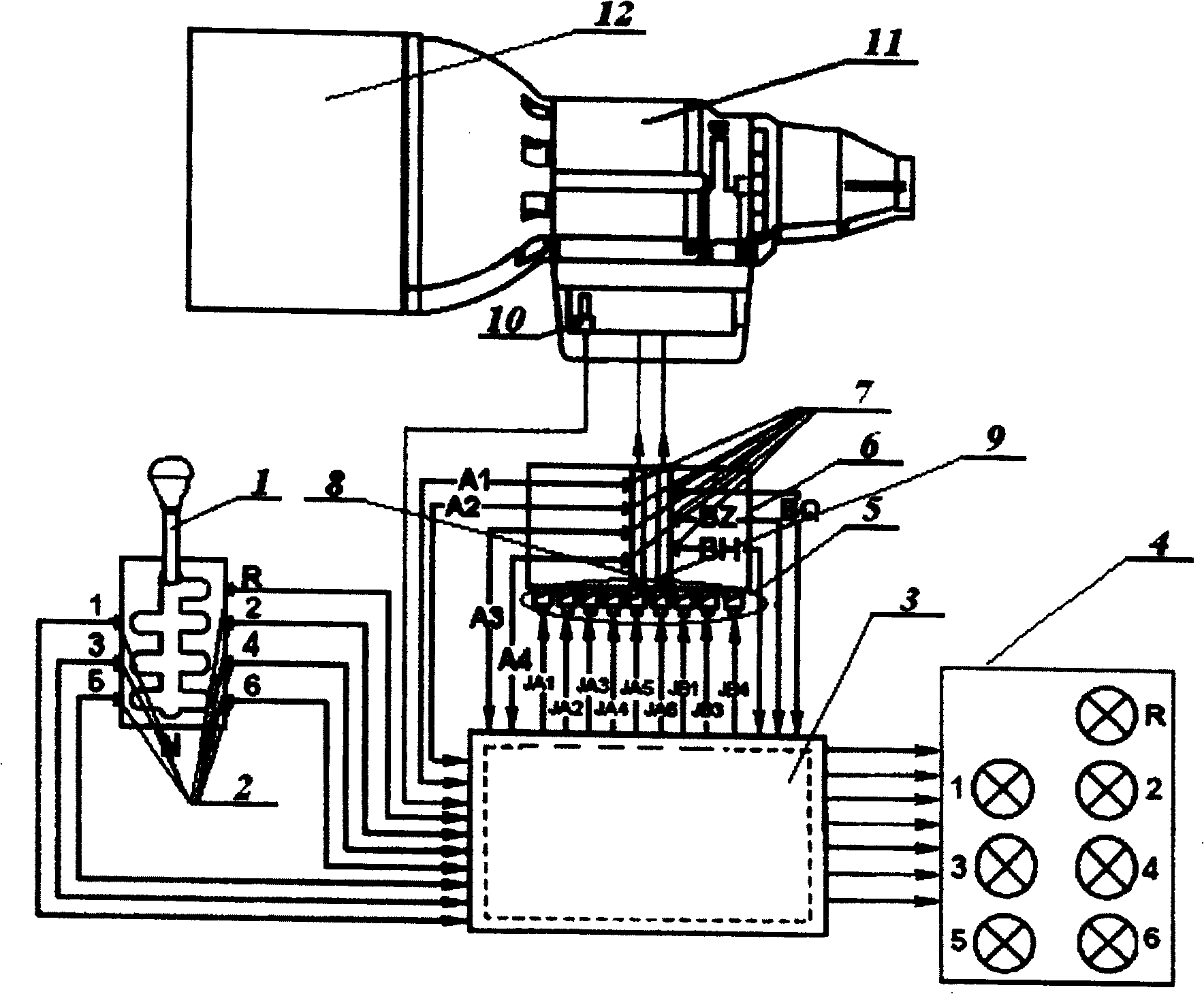

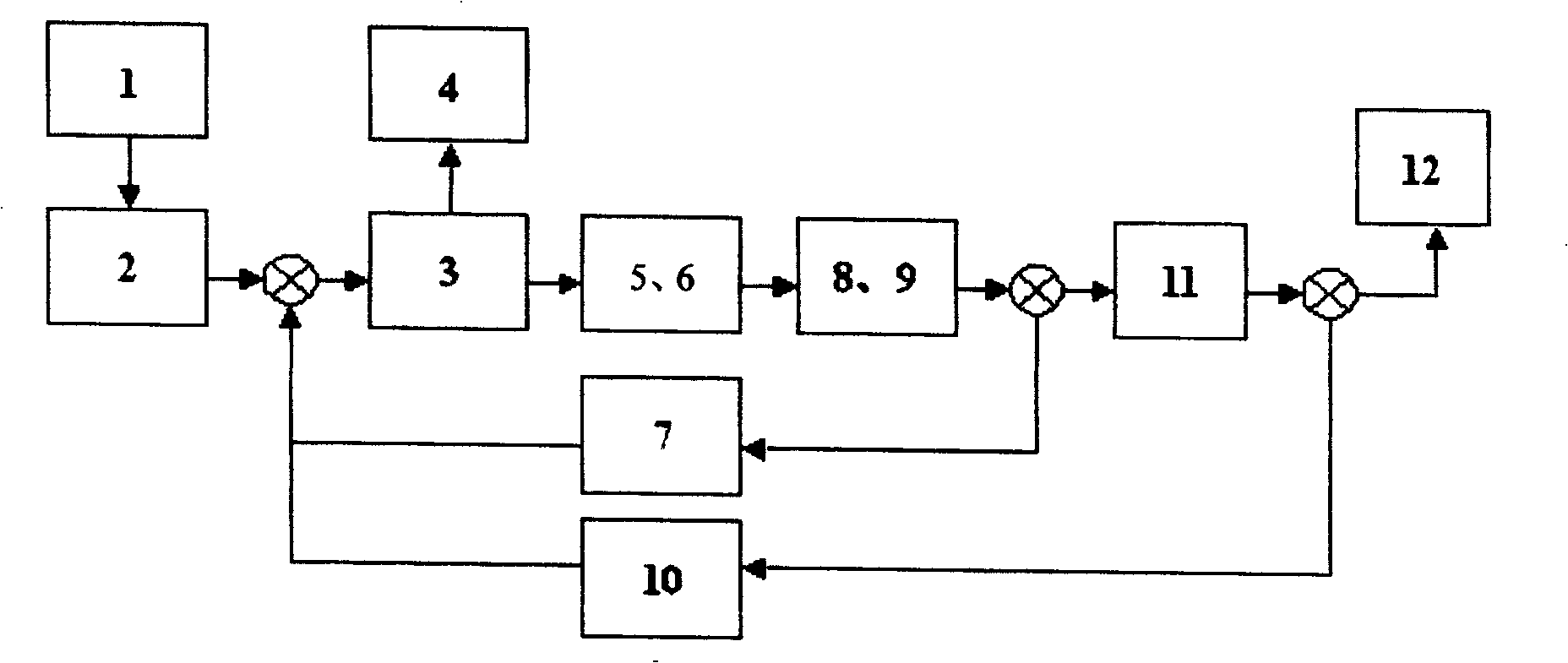

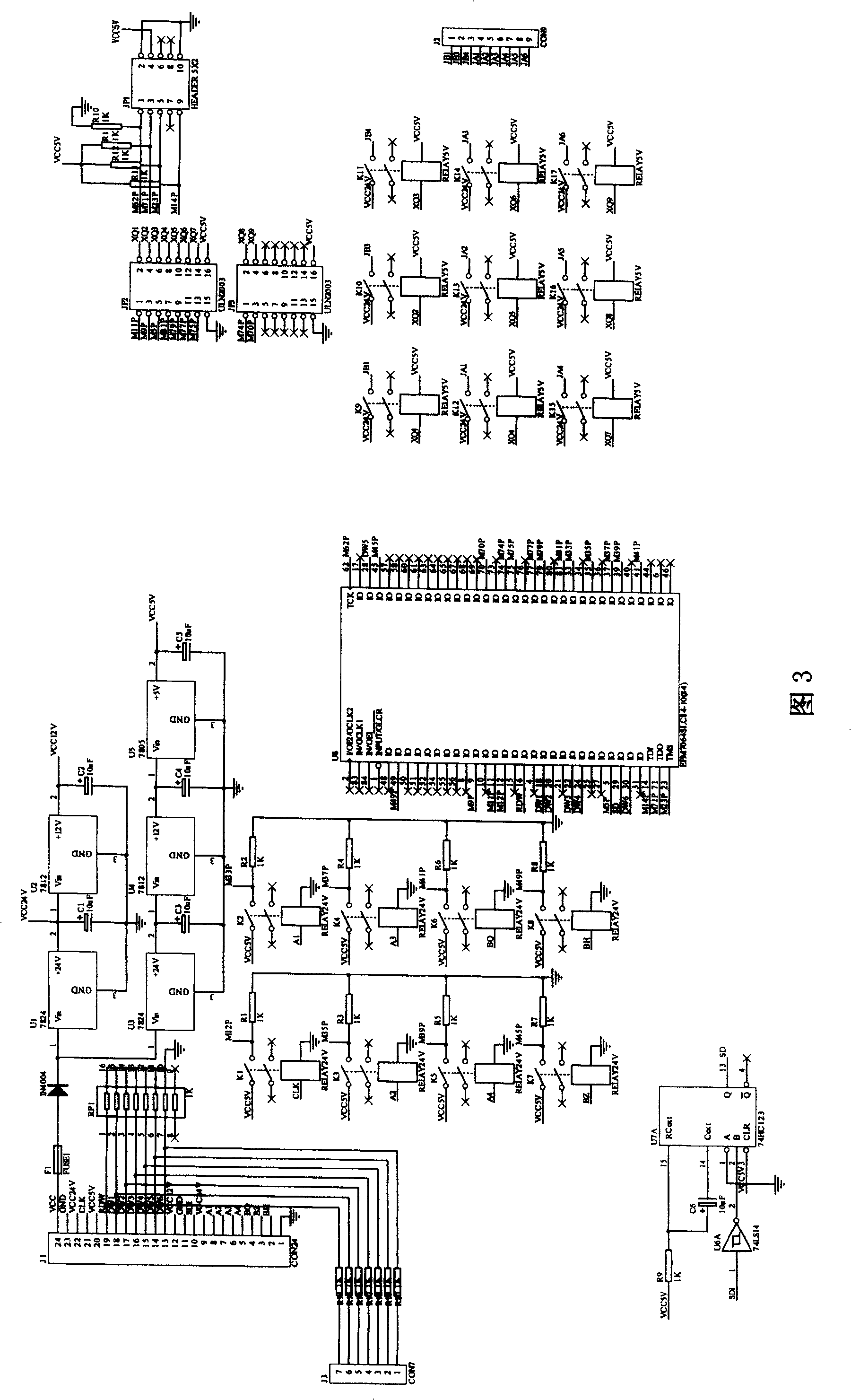

[0056] Such as figure 1 As shown, the gearbox control device of the manual shift vehicle includes a shift lever 1, a gear switch sensor 2, a CPLD main control module 3, an electronically controlled reversing valve 6, an A cylinder 8, a B cylinder 9, and a cylinder in place The switch sensor 7 and the gear switch sensor 2 are installed at the 1, 2, 3, 4, 5, 6, N, and R gears of the base of the automobile shift lever 1, the gear switch sensor 2, and the cylinder in-position switch sensor 7 They respectively include return spring, spring leaf, and contact. One end of the contact is connected to the power supply, and the other end is connected to the CPLD main control module 3. When the shift lever 1 is moved to any gear position, the corresponding gear switch sensor 2 is immediately sucked. close, the power signal is transmitted to the CPLD main control module 3 through the contact of the pull-in, and the 9 drive coils 5 (JA1, JA2, JA3, JA4, JA5, JA6, JA4, JA5, JA6, JB1, JB3, JB...

Embodiment 2

[0059] When shifting from neutral N to first gear, if figure 1 , 2 , Shown in 3, the shift control step of this device is:

[0060] (1) The driver depresses the clutch, pushes the shift lever 1 from the N gear to the 1st gear, the contact of the gear switch sensor 2 of the 1st gear is closed, and the gear position signal is transmitted to the CPLD main control module 3;

[0061] (2) According to the gear position signal of the gear switch sensor 2 and the vehicle speed signal of the vehicle speed sensor 10, the CPLD main control module 3 judges that the shift intention is 1st gear, which is valid, and then the CPLD main control module 3 outputs the gear position signal to the gear position in real time The display circuit 4 realizes the real-time display of the gear position. Because it is an advanced gear, and according to Table 1 and Table 2, the CPLD main control module 3 first outputs the drive signal of 24V to the corresponding drive coil 5 of the A cylinder 8, that is, ...

Embodiment 3

[0064] When shifting from 3rd gear to N gear, if figure 1 , 2 , Shown in 3, the shift control step of this device is:

[0065] (1) The driver depresses the clutch and pushes the shift lever 1 from the 3rd gear to the N gear. At this time, the contacts of the 1, 2, 3, 4, 5, 6 and R gear switch sensor 2 all bounce off;

[0066] (2) According to the state that all the contacts of the gear switch sensor of 1, 2, 3, 4, 5, 6 and R are bounced off and the vehicle speed signal of the vehicle speed sensor 10, the CPLD main control module 3 judges that the shifting intention is the N gear , effective, then the CPLD main control module 3 outputs signals to the stall real-time display circuit 4 to realize the real-time display of the stalls, because it is out of gear, and according to Table 1 and Table 2, the CPLD main control module 3 first outputs the drive signal of 24V to the The corresponding driving coil 5 of the B cylinder 9, that is, energizes the driving coils JB1 and JB4 to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com