Front-mounted furrow-opening machine

A ditching machine and front-mounted technology, which is applied in the direction of digging/covering ditches, farming equipment, agricultural machinery and equipment, etc., can solve the problems of easy subsidence in wet fields of tractors, de-oiling and flameout of engines, unfavorable diesel engine power, etc., to achieve Promote the effect of wide practical value, lighten load, improve linearity and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

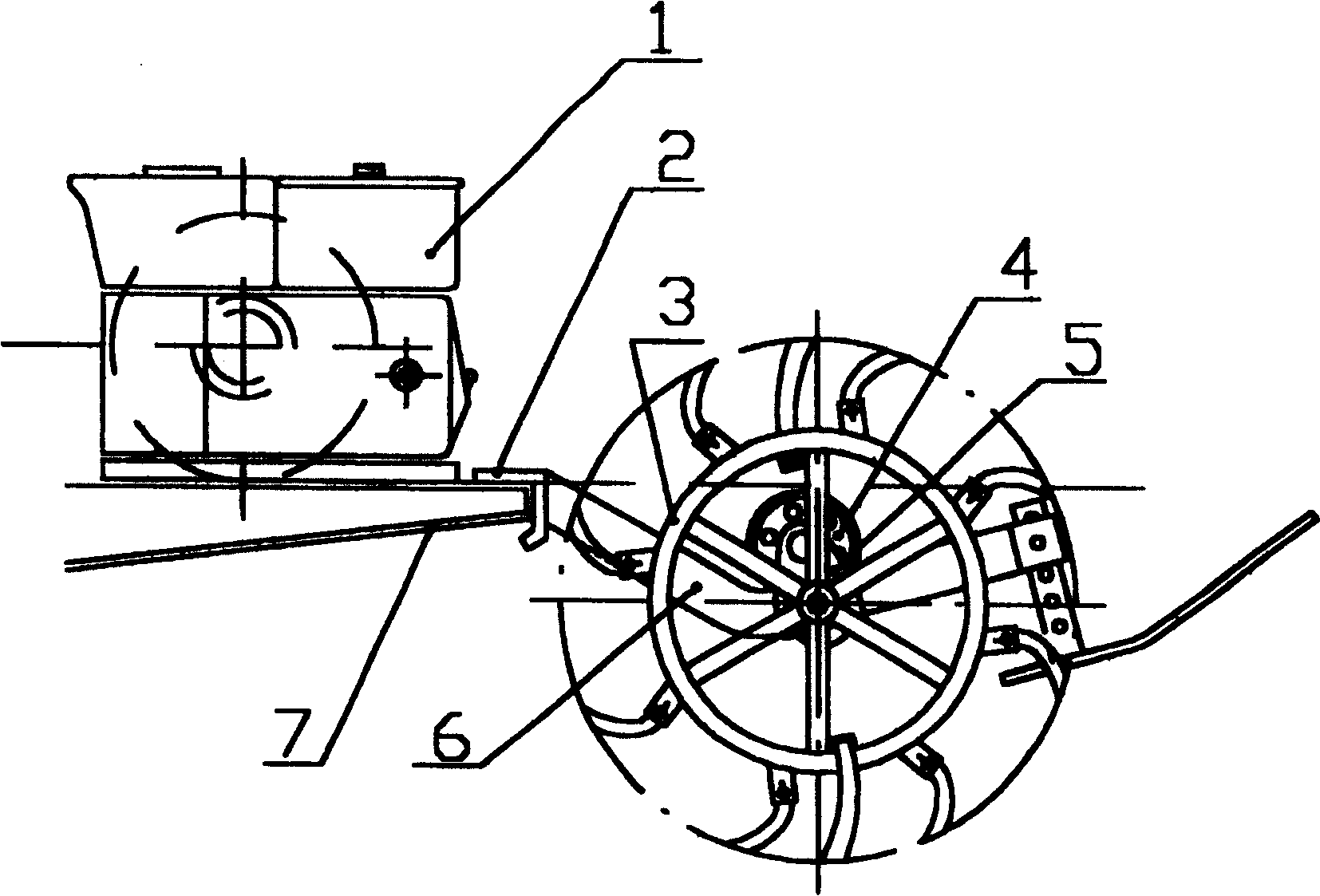

[0013] 1. Refer to the attached figure 1 , using the The frame arm 6 in the bent state, the frame arm 6 in the trencher frame assembly is connected with the tractor frame 7 through the frame seat 2, and the rear section of the frame arm 6 in the frame assembly is inclined downward, The front section is upturned, and the gear box 5 is installed on the upturned section, and the cutter head 3 and the belt pulley 4 are installed on the gear box. Gear box 5 and the belt pulley 4 of gear box 5 tops are inclined backward.

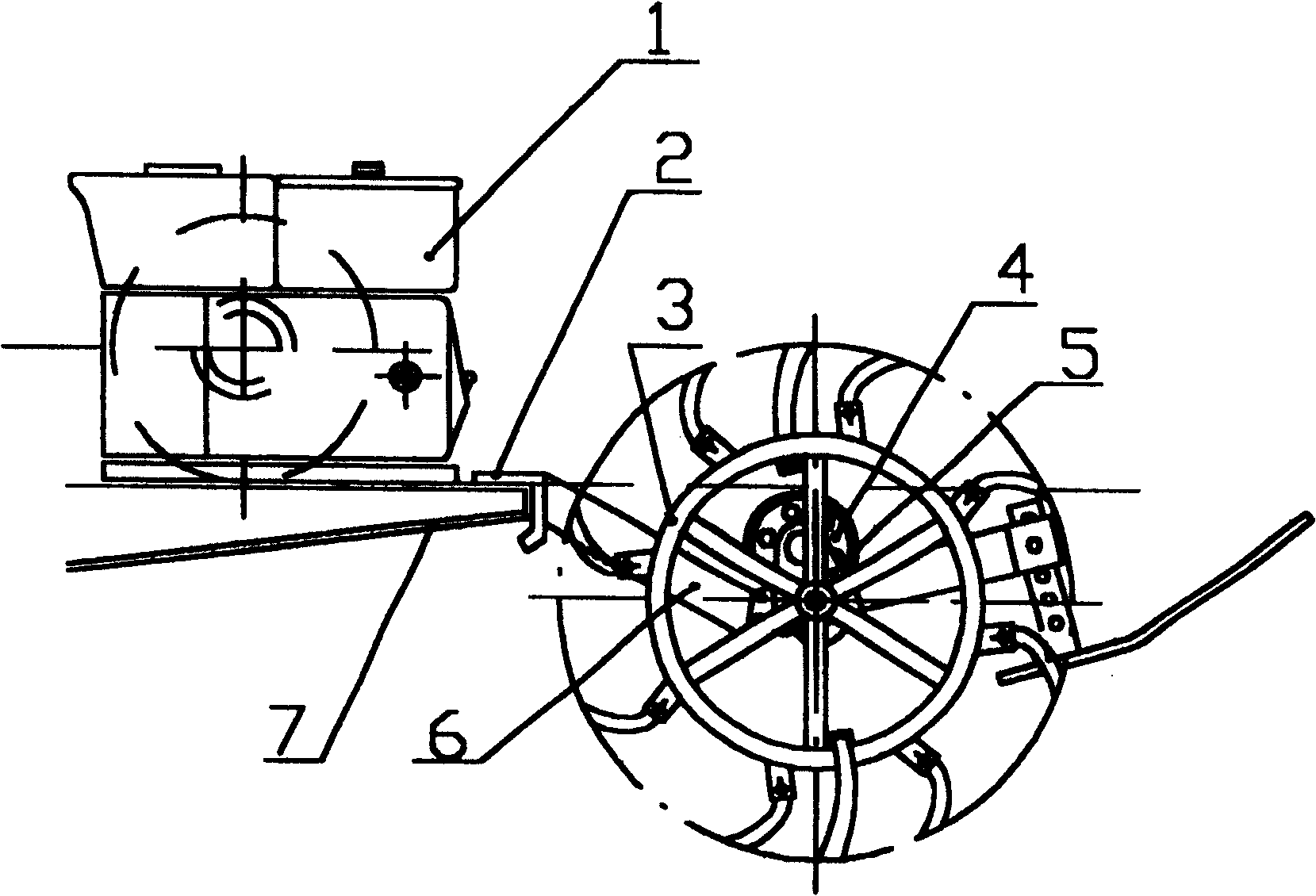

[0014] 2. Refer to the attached figure 2 , using a structure consisting of two rods connected The frame arm 6 in the bent state, the frame arm 6 in the ditching machine frame assembly is connected with the tractor frame 7 through the frame seat 2, the rear section of the frame arm 6 is inclined downward, and the front section is tilted upward, upward Gear box 5 is installed on the warped section, and cutter head 3 and belt pulley 4 are installed on the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com