Method for extracting allium sativum oil and allium sativum polyose from garlic by supercritical CO2

A technology of garlic polysaccharide and garlic oil, which is applied in the direction of fat oil/fat production, fat production, bulk chemical production, etc., can solve the problems of increased process, low comprehensive utilization value of garlic, and difficult filtration, etc., achieves no solvent residue, provides comprehensive The effect of using value and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Peel the fresh garlic, weigh 10kg, and put the whole grain into the hanging basket of the extraction kettle. The pressure was 5 MPa, the temperature was 45°C, and dynamic extraction was performed for 3 hours to obtain 33 grams of garlic oil with an allicin content of 56%. The extraction kettle released 3.6 kilograms of juice, boiled, filtered, and evaporated to dryness to obtain 680 grams of garlic polysaccharide.

Embodiment 2

[0021] Peel the fresh garlic, weigh 10kg, slice it, and put it into the hanging basket of the extraction kettle. The pressure is 5MPa and the temperature is 45°C. Dynamically extract for 3 hours to obtain 32 grams of garlic oil with an allicin content of 60%, 4.2 kilograms of juice is released from the extraction kettle, boiled, filtered, and evaporated to dryness to obtain 750 grams of garlic polysaccharide.

Embodiment 3

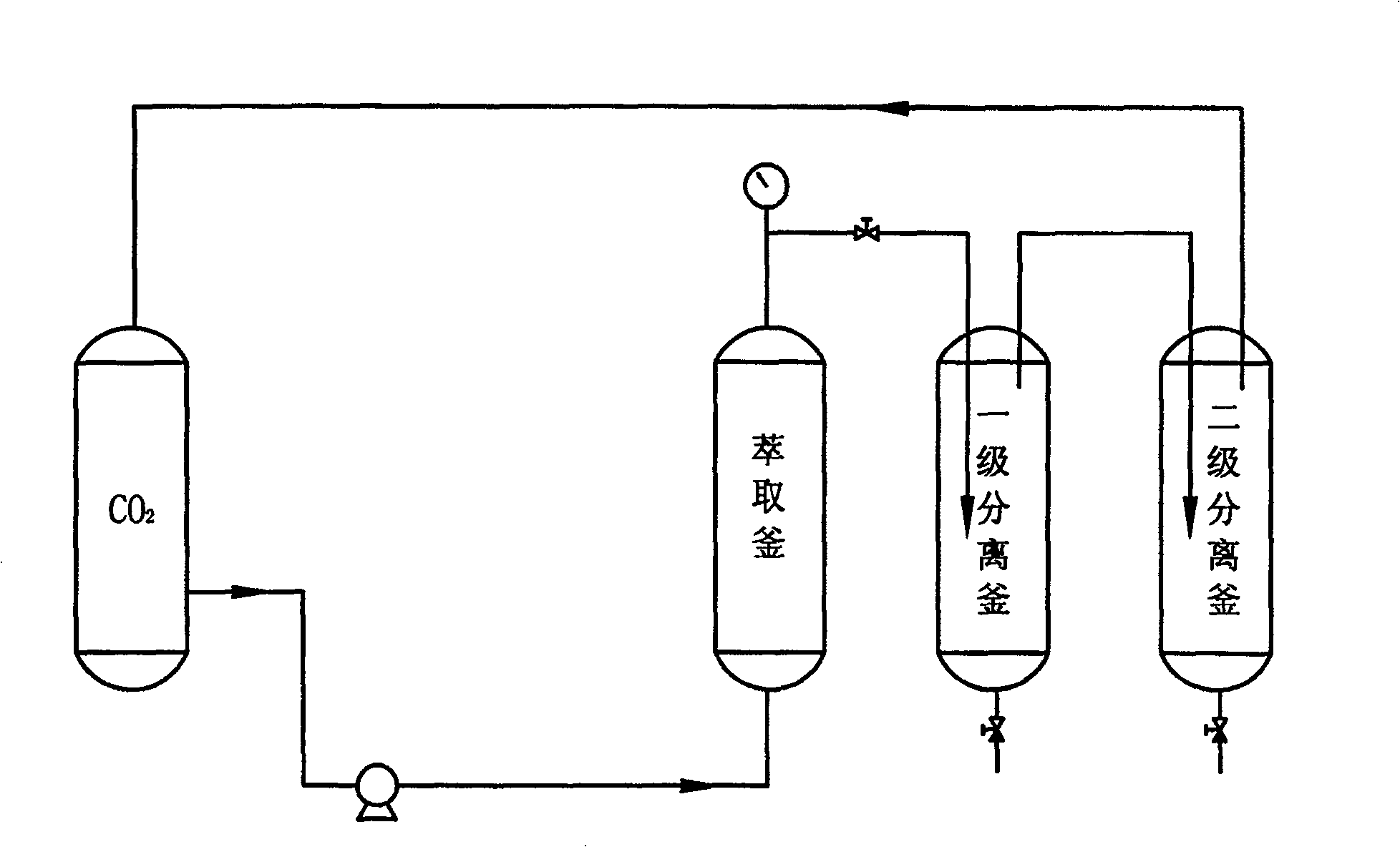

[0023] Fresh garlic is peeled, weighed 10kg, sliced, put into the hanging basket of extraction kettle, the pressure of control extraction kettle is 25MPa, and temperature is 40 ℃, static extraction 3 hours; The pressure of extraction kettle is 25MPa, and temperature is 40 ℃, The pressure of the primary separation kettle is 9MPa, and the temperature is 45°C; the pressure of the secondary separation kettle is 5MPa, and the temperature is 45°C; dynamic extraction for 3 hours obtains 34 grams of garlic oil with a content of 58% allicin, and 4.8 kilograms of juice is released from the extraction kettle. Boil, filter, and evaporate to dryness to obtain 780 grams of garlic polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com