Formula and production method of stable-flavor low horseradish green mustard

A technology of horseradish green mustard and preparation method, which is applied in the fields of food ingredients as antioxidants, food science, food preservation, etc., can solve the problem of not taking into account the volatilization of isothiocyanate, the lack of in-depth research on the degree of hydrolysis of wasabi sauce, and wasabi. It can enhance the antioxidant effect, prevent precipitation, and reduce water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

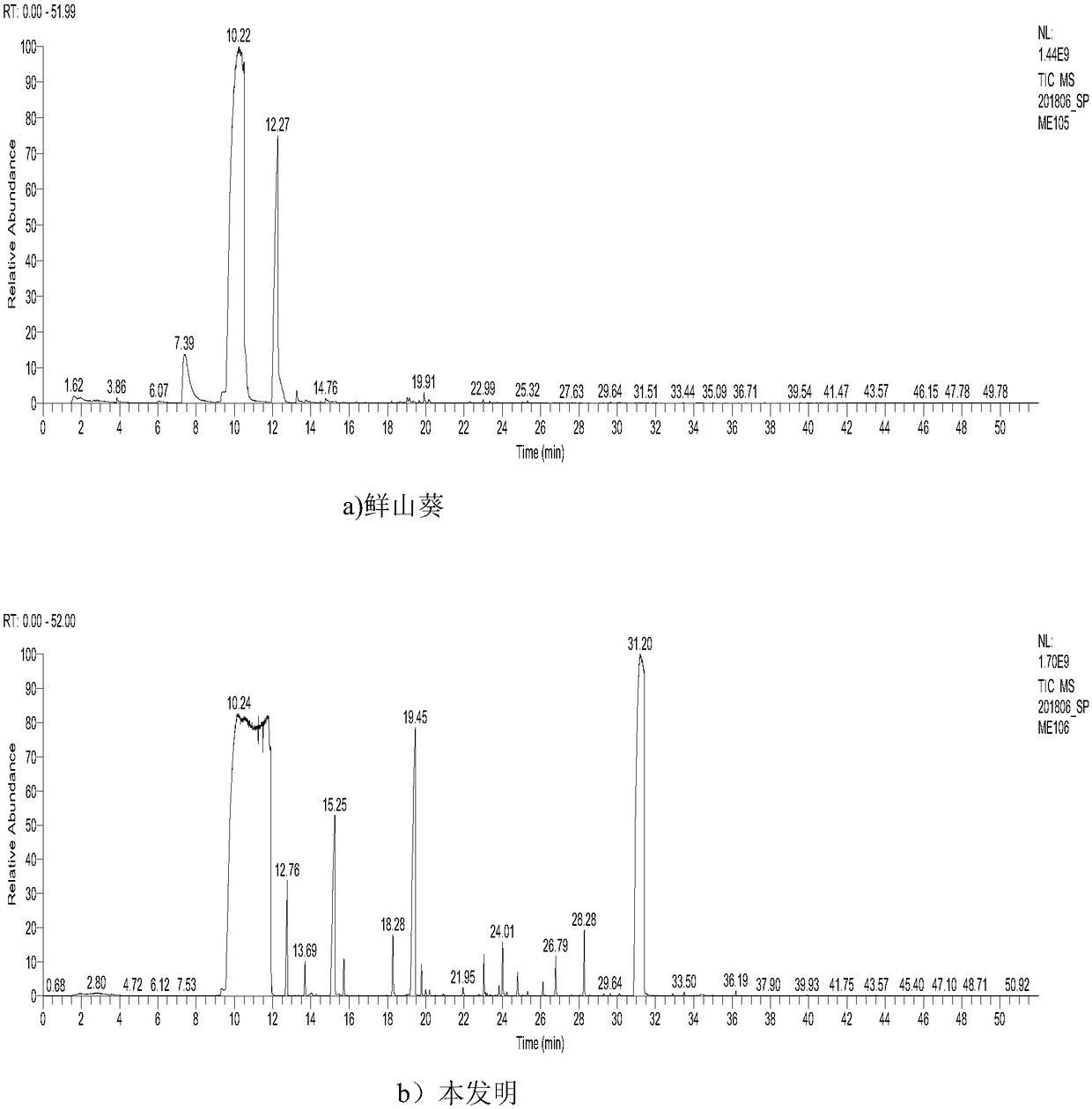

[0035] Embodiment 1 A kind of formula and preparation method of low horseradish and partial sweet green wasabi with stable flavor

[0036] A low-sweet horseradish and green wasabi formula with stable flavor, by weight, the formula ratio is as follows: 18 parts of horseradish powder, 3 parts of horseradish powder, 60 parts of water, 5 parts of soybean oil, 2 parts of edible salt, sorbet 10 parts of sugar alcohol, 4 parts of corn starch, 0.2 part of xanthan gum, 0.4 part of sodium polyphosphate, 0.5 part of glyceryl monostearate, 0.01 part of ascorbic acid, 0.5 part of gluten protein, and 0.1 part of citric acid. Compared with the isothiocyanate in fresh wasabi, the prepared low-horseradish wasabi during storage period was 0.17μL / mL higher.

[0037] Its production method is as follows:

[0038] (1) Drying: fresh wasabi was washed and sliced, and 200 g of frozen samples were put into a pulse-spray microwave freeze dryer to dry to the end at 2 W / g. The drying parameters were: cold ...

Embodiment 2

[0045] Embodiment 2 A kind of formula and preparation method of low-horseradish partial-acid green wasabi with stable flavor

[0046] A kind of low horseradish partial sour wasabi formula with stable flavor, by weight, the proportion of the formula is as follows: 18 parts of horseradish powder, 3 parts of horseradish powder, 60 parts of water, 5 parts of soybean oil, 2 parts of edible salt, sorbet 5 parts of sugar alcohol, 4 parts of corn starch, 0.2 part of xanthan gum, 0.4 part of sodium polyphosphate, 0.5 part of glyceryl monostearate, 0.02 part of ascorbic acid, 0.5 part of gluten protein, and 0.2 part of citric acid. Compared with the isothiocyanate in fresh wasabi, the prepared low-horseradish wasabi during storage period was 0.19 μL / mL higher.

[0047] Its production method is as follows:

[0048] (1) Drying: fresh wasabi was washed and sliced, and 200 g of frozen samples were put into a pulse-spray microwave freeze dryer to dry to the end at 2 W / g. The drying paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com