On-line full automatic sodium ion concentration analyzer

A technology of concentration analyzer and sodium ion, which is applied in the field of online sodium ion concentration analyzer, can solve the problems of poor measurement accuracy, long operation time, and inability to realize automation, and achieve increased maintenance costs, long service life, and short service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

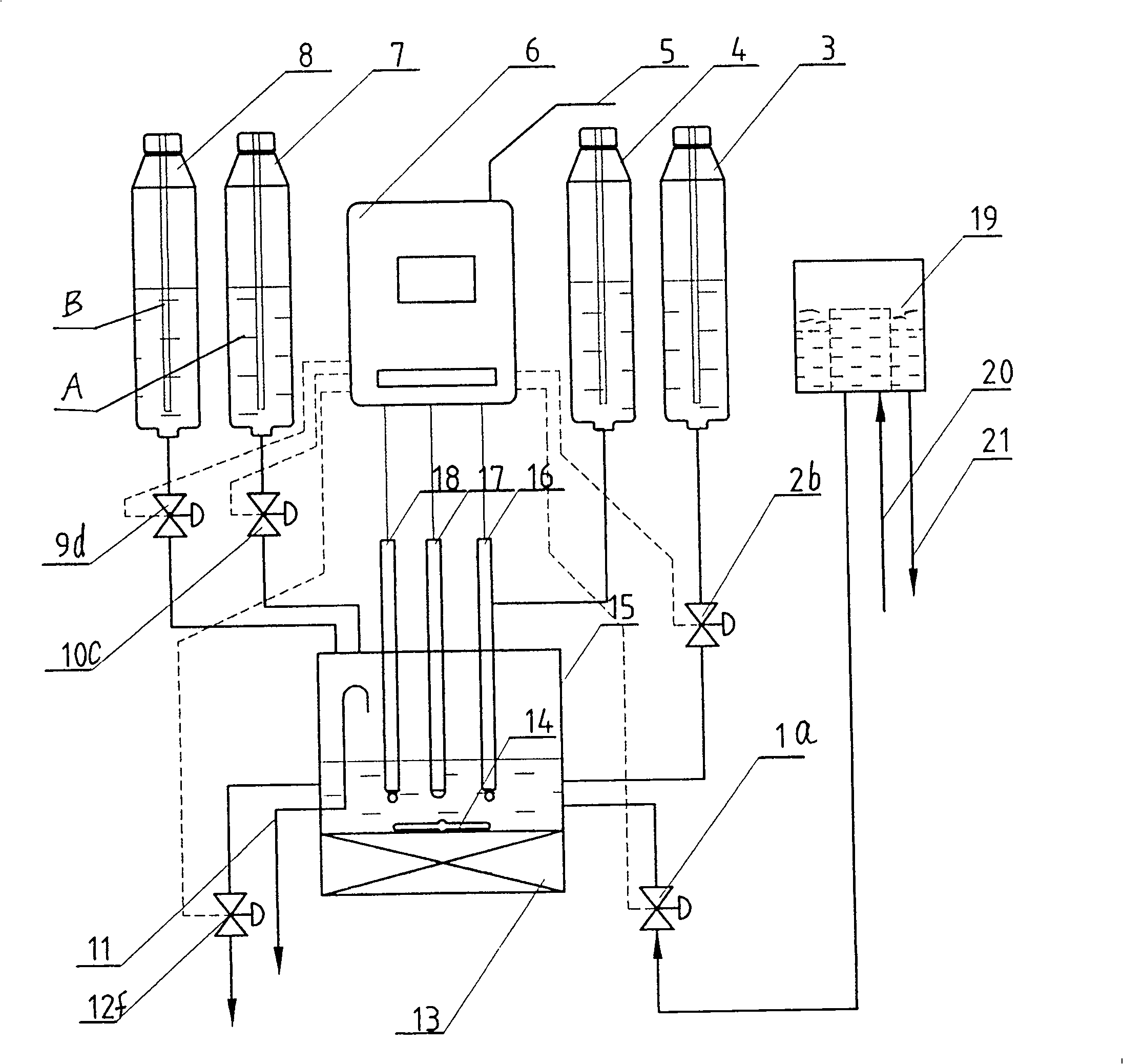

[0018] Embodiment 1: refer to figure 1 , on-line fully automatic sodium ion concentration analyzer, its special feature is that it includes a measuring cell 15, the built-in sodium ion electrode 18, reference electrode 16 and temperature electrode 17 in the measuring cell 15 are all connected with the remote communication control interface 5 The secondary intelligent instrument 6 is electrically connected, the reference electrode 16 is connected with the supplementary electrolyte box 4, and the sample liquid level constant level tank 19 set at any position exceeding the height of the measuring pool 15, and the constant pressure type controllable timing are injected into the alkalization reagent Box 3, constant pressure controllable timing injection of standard sample A and standard sample B. Standard sample boxes 7 and 8 are connected to measuring pool 15 through respective control valves 1a, 2b, 10c, 9d, and control valves 1a, 2b, 10c , 9d are electrically connected with the ...

Embodiment 2

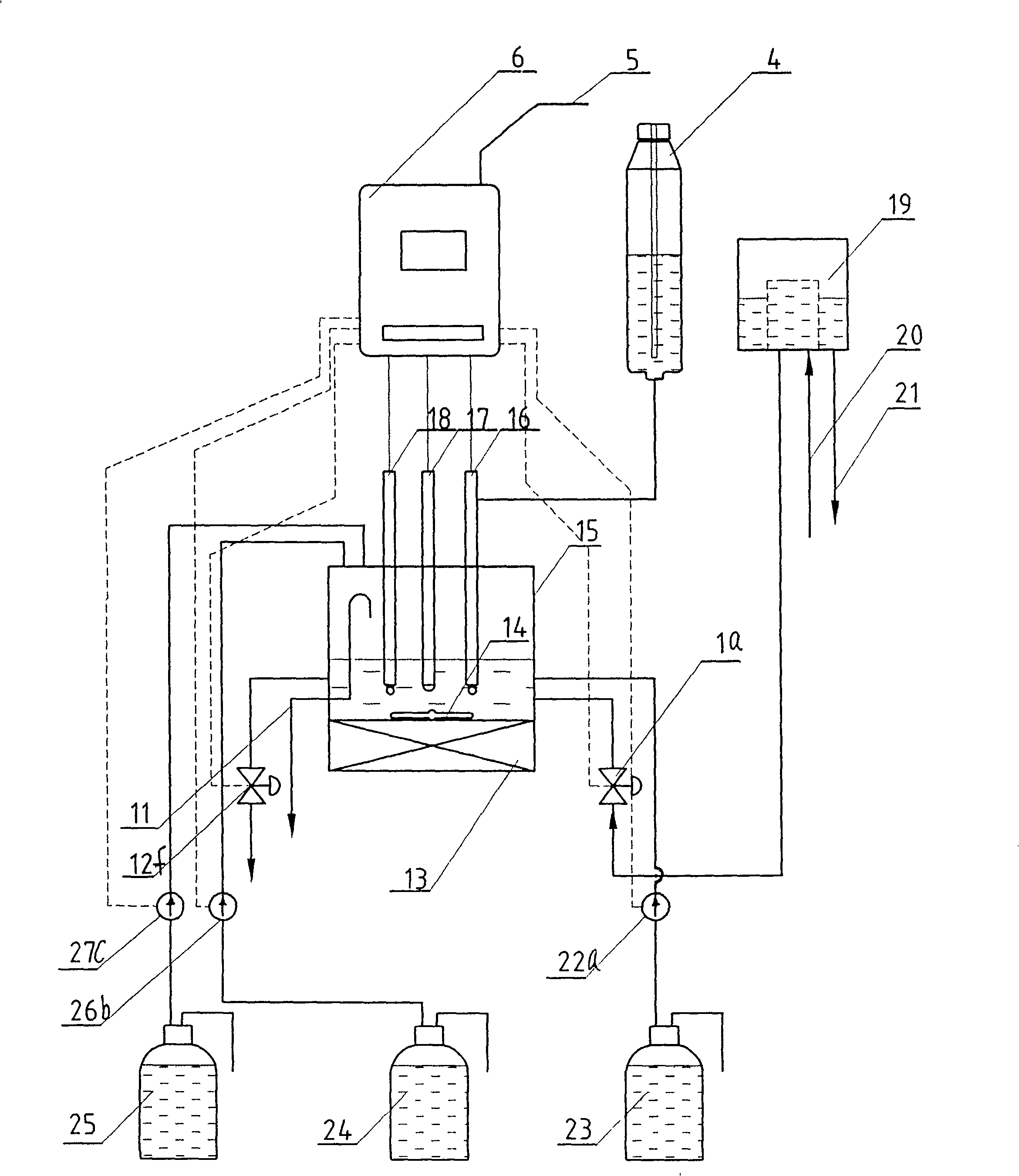

[0020] Embodiment 2: refer to figure 2 , the structure of the on-line full-automatic sodium ion concentration analyzer of embodiment 2 is basically the same as that of embodiment 1, and the difference is only: the standard sample bottle 24 and the standard sample bottle 23 of the alkalization reagent bottle 23, standard sample A and standard sample B that are provided with 25 are all connected to the measuring pool 15 through respective metering pumps or peristaltic pumps 22a, 26b, 27c, and the metering pumps or peristaltic pumps 22a, 26b, 27c are electrically connected to the secondary smart meter 6 with the remote communication control interface 5. The alkalization reagent bottle 23, the metering pump or the peristaltic pump 22a are used to replace the constant pressure controllable timing injection of the alkalization reagent box 3 and the control valve 2b in the embodiment 1. The standard sample vials 24 and 25 of the standard sample A and the standard sample B replace th...

Embodiment 3

[0021] Embodiment 3: refer to image 3 , the structure of the on-line fully automatic sodium ion concentration analyzer of embodiment 3 is basically the same as that of embodiment 2, and the only difference is that: or the sample liquid is connected with the measuring pool 15 through a metering pump or a peristaltic pump 28e, and the metering pump or a peristaltic pump 28e is electrically connected with the secondary smart meter 6 having the remote communication control interface 5 .

[0022] Metering pumps or peristaltic pumps 22a, 26b, 27c and 28e have the same structure, and commercially available precision metering pumps or peristaltic pumps are selected.

[0023] refer to figure 1 , taking Example 1 as an example to describe the measurement and calibration process in detail.

[0024] 1. Measurement process:

[0025]The measured water sample 20 enters the water sample constant level tank 19, and the water sample enters the measuring tank 15 through the control valve 1a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com