Pneumatic tailstock of numerically controlled lathe

A technology of CNC lathes and tailstocks, which is applied in the direction of tailstocks/tops, turning equipment, tool holder accessories, etc., which can solve the problems of axial clearance, reduce the service life of equipment, and reduce machining accuracy, so as to achieve low rolling friction coefficient, The effect of high mechanical movement precision and small guide gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

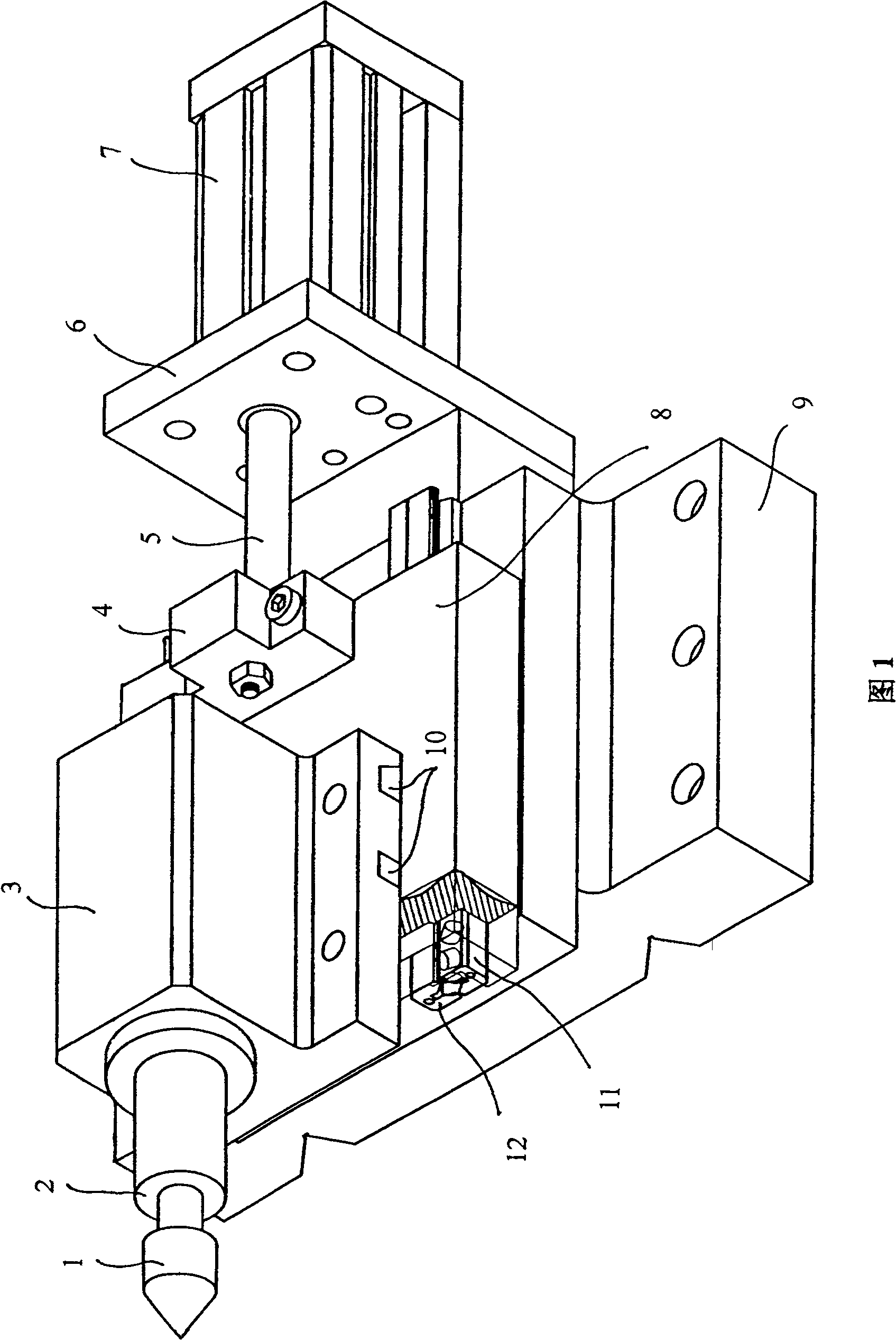

[0018] As shown in Figures 1 to 4, the CNC lathe pneumatic tailstock includes a base 9 installed on the guide rail of the CNC lathe. The two guide rail grooves on the bottom surface of the base can be adjusted axially along the lathe guide rail, especially when processing short materials. Adjust accordingly, and fix the base after adjustment.

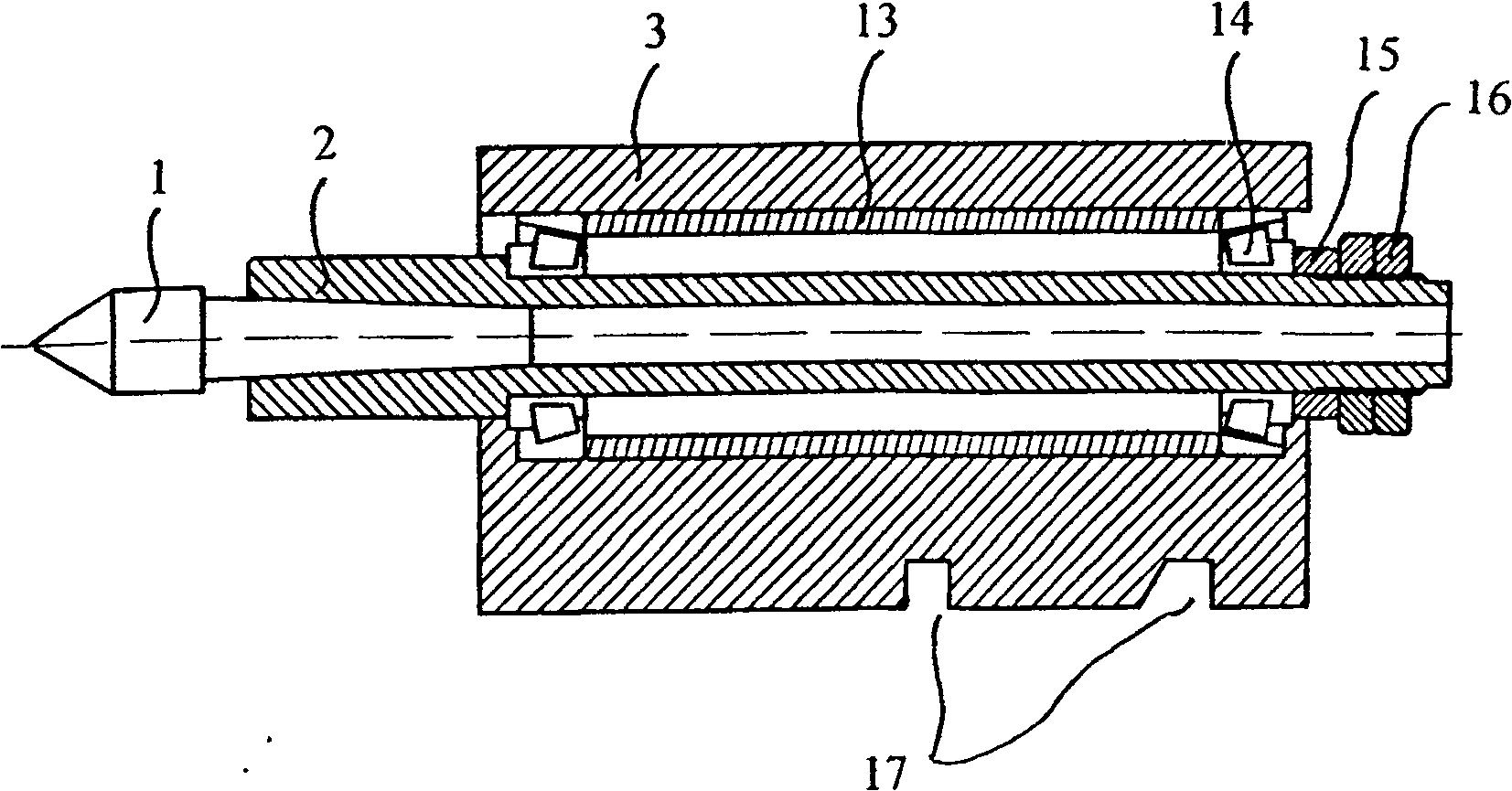

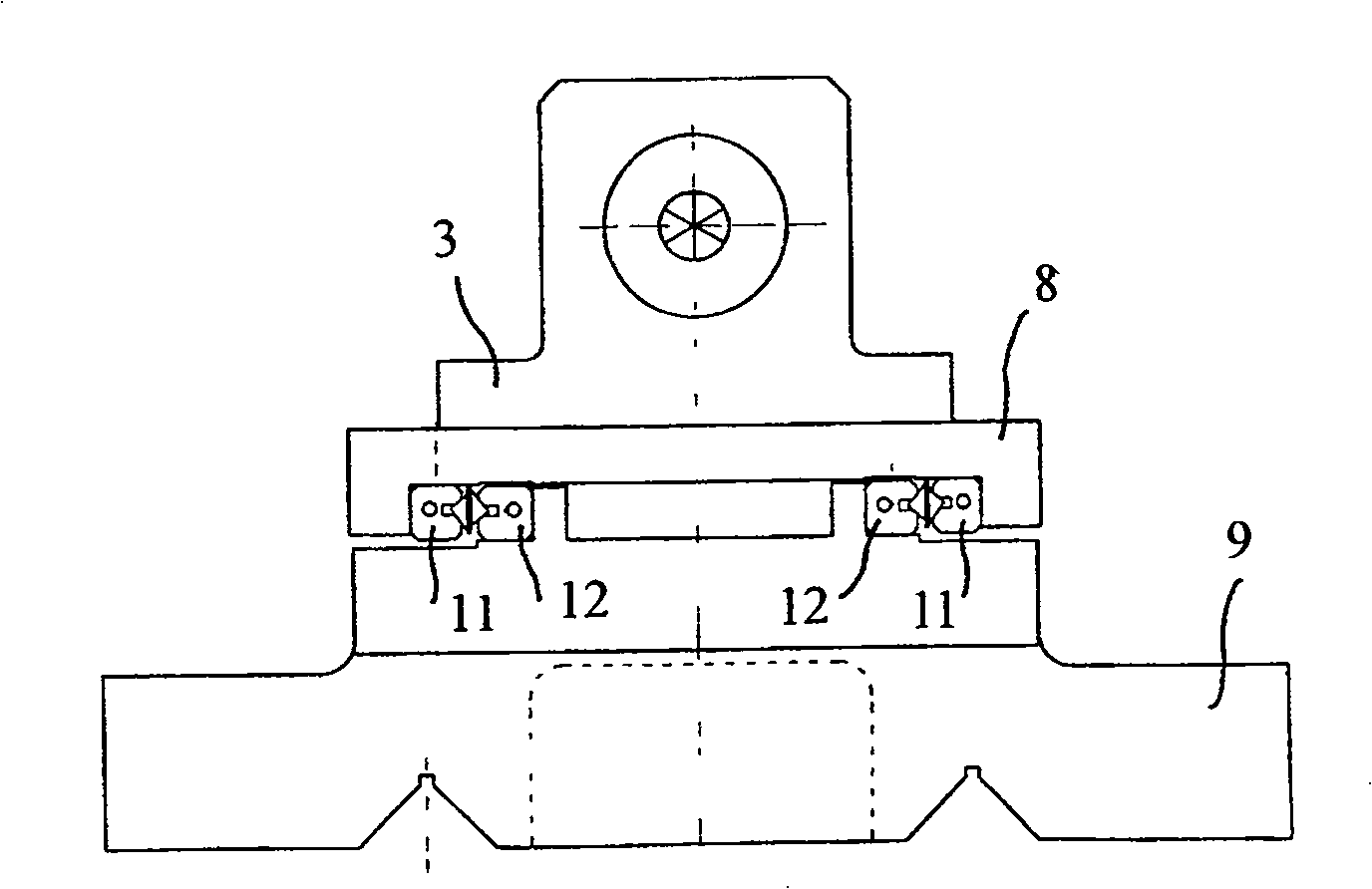

[0019] The carriage 8 is arranged on the top of the base, and can be adjusted for axial sliding relative to the base. The sliding adjustment is realized by a pair of rolling guide rails arranged between the base and the carriage. The pair of rolling guide rails described in this application are The patent structure of the patent No. 02260472.3 obtained by the person first, the rolling friction part of the rolling guide rail is composed of a fixed guide rail 12 and a rolling guide rail 11 with a cage 19 separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com