Method and device for producing a low-shrinking smooth yarn

A low-shrinkage, straight-filament technology that is used in stretch spinning, textile and papermaking, heat treatment of rayon, etc., and can solve problems such as unstable filaments, large spanning distances, feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

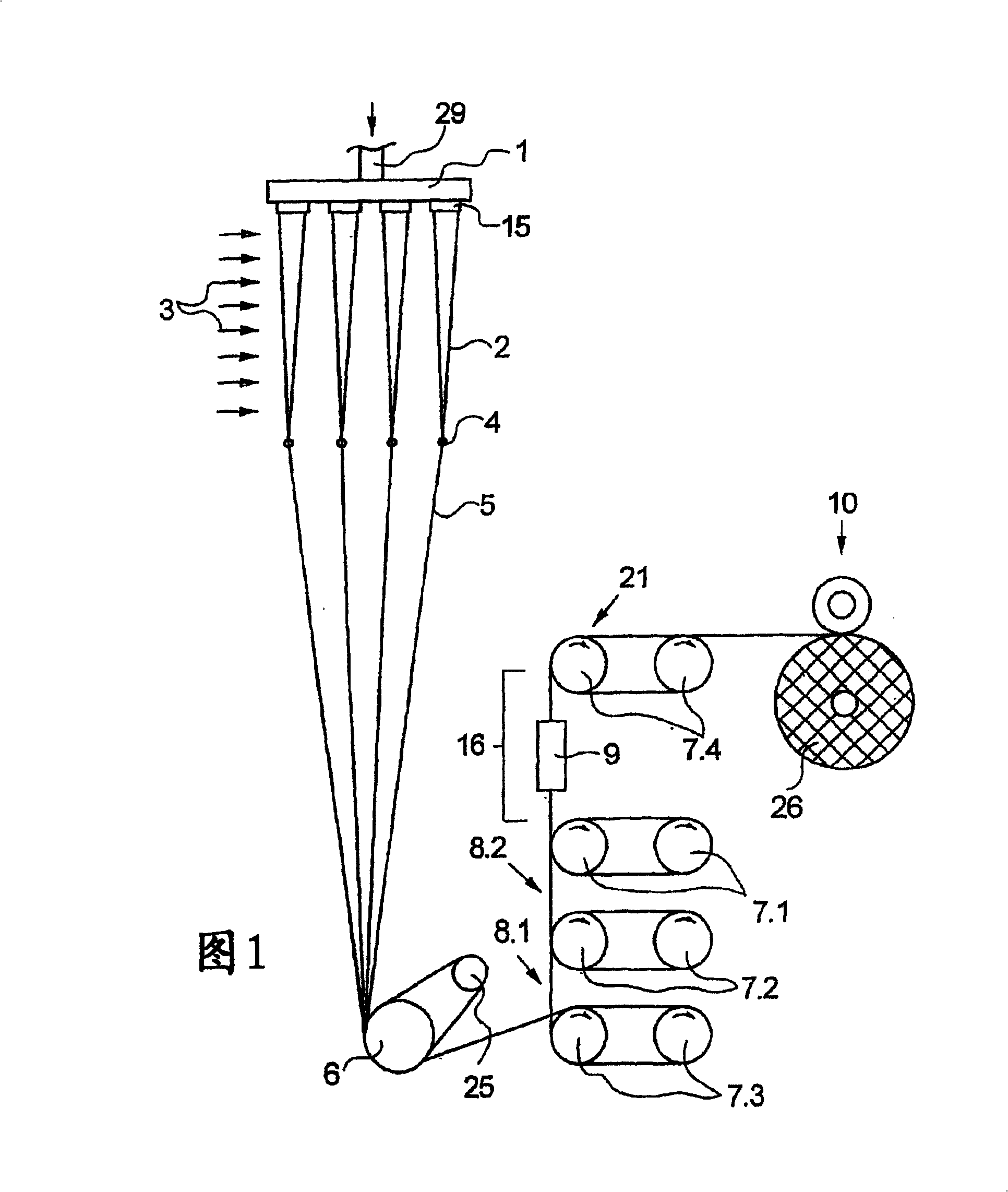

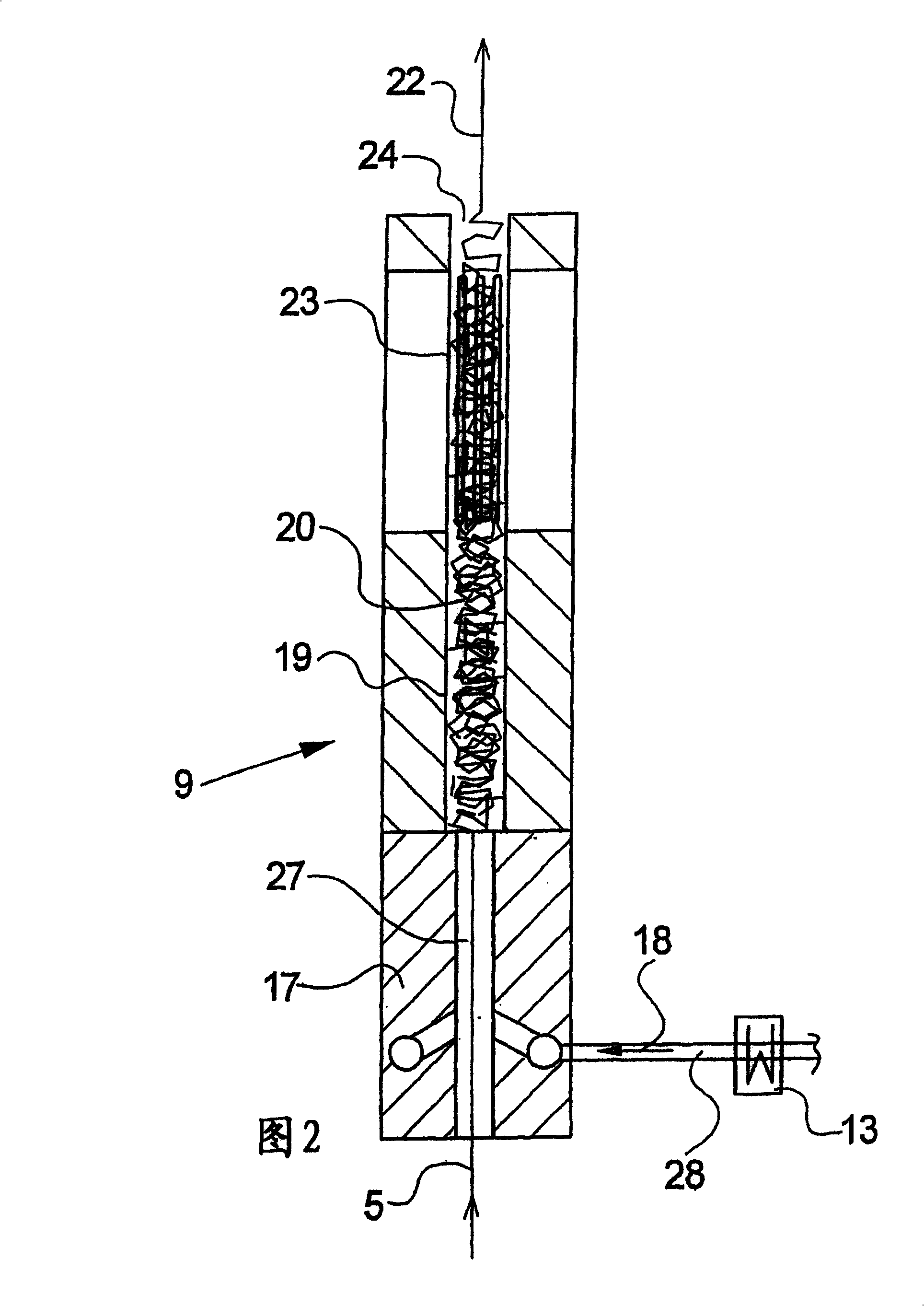

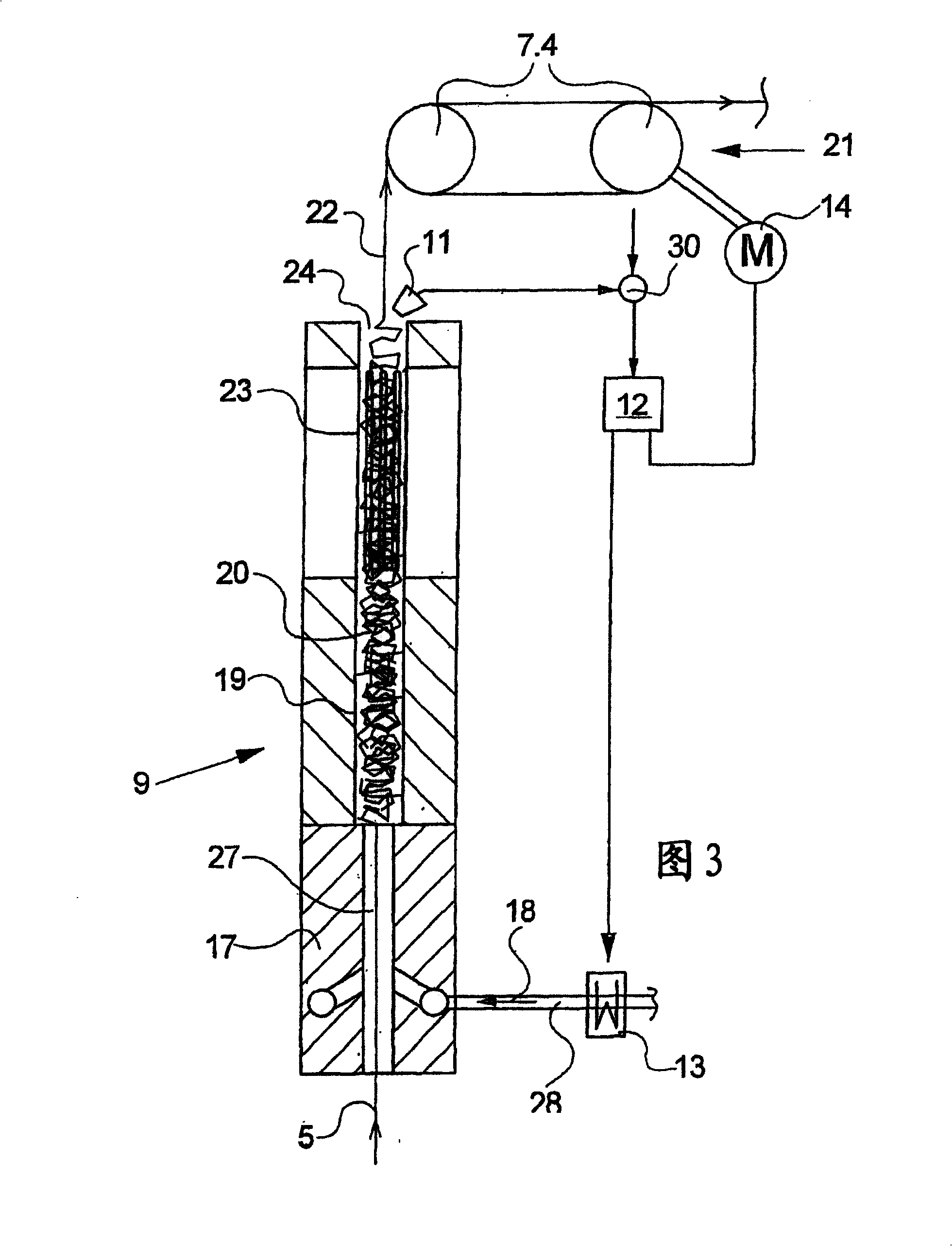

[0023] Figure 1 is a schematic diagram of a first embodiment of an apparatus according to the invention, in which the method of the invention is employed.

[0024] The apparatus comprises a spinning device, wherein the spinning device is formed by a spinning head 1 and a set of spinnerets 15 . The spinneret 1 is connected via a melt feed line 29 to a melt source (not shown here), for example to an extruder. A set of spinnerets 15 is installed on the underside of the spinning head 1, and each spinneret 15 includes a set of spinneret holes through which a single filament bundle 2 is respectively extruded. In this embodiment, for example four spinnerets 15 are shown.

[0025] After extrusion, the individual filament bundles 2 are cooled by cooling air 3 , oiled and moistened in an oiling device 4 and combined into a filament 5 . Although the above description is directed to multifilament filaments, it is basically applicable to monofilament filaments as well.

[0026] After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com