Waterless taphole mix for blast furnace taphole

A technology of anhydrous taphole mud and taphole, which is applied in the field of refractory materials, can solve the problems of long-time blast furnace tapping, skin and mucous membrane irritation, low high-temperature strength of taphole mud, etc., and achieve good high-temperature strength and slag resistance Erosion, good workability, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

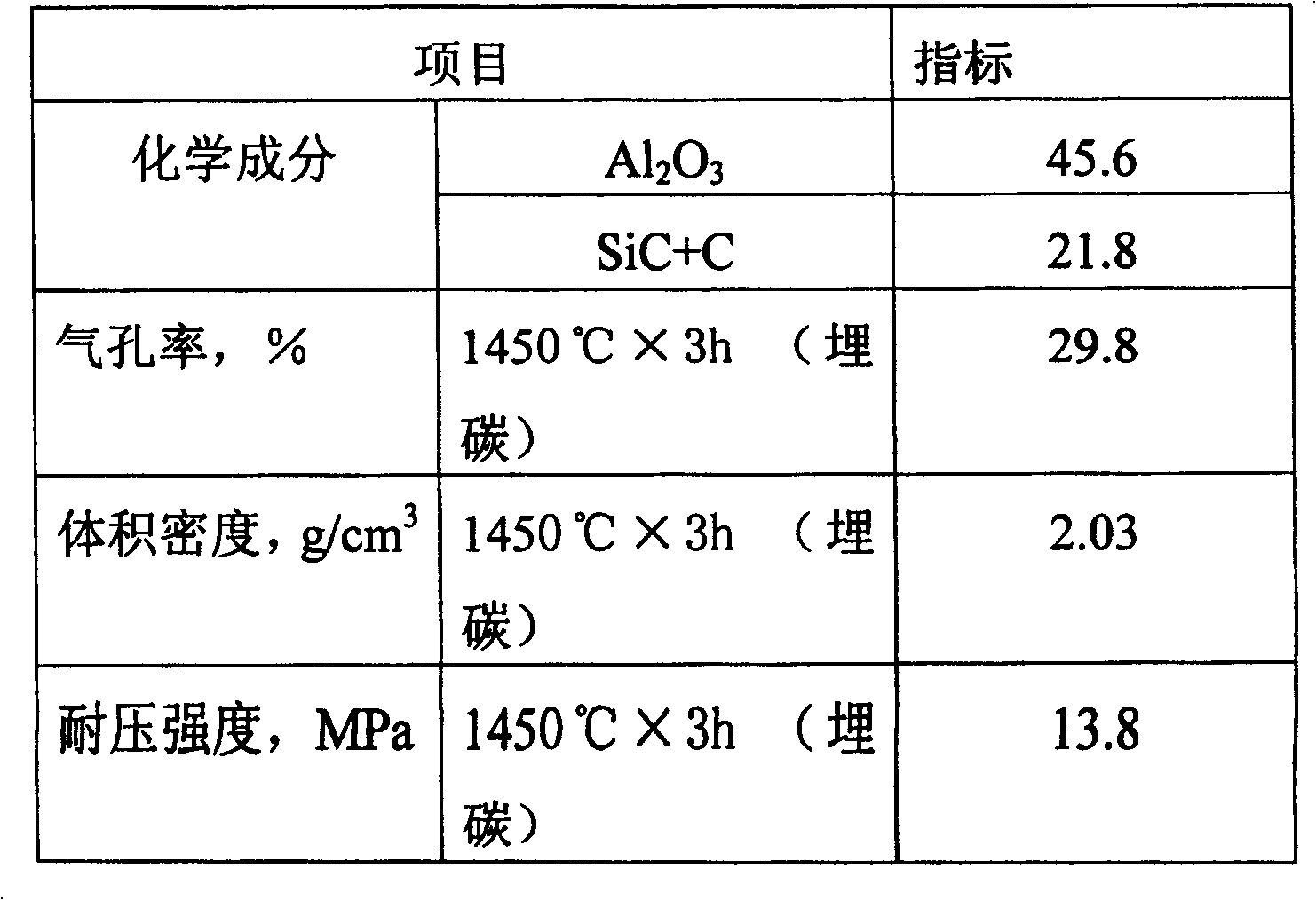

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

[0051] Take the raw material by the following parts by weight:

[0052] Brown corundum 3-1mm 30 parts

[0053] Brown corundum powder 0.074-0mm 17 parts

[0054] Kyanite 1-0mm 5 parts

[0055] SiC 0.074-0mm 15 parts

[0056] Guangxi white mud 0.088-0mm 10 parts

[0057] Sericite powder 0.074-0mm 8 parts

[0058] Coke 2-0mm 20 parts

[0059] Metal silicon powder 0.044-0mm 1 part

[0060] Carbon black 0.5 parts

[0061] Modified polymer 13 parts

[0062] 5 parts powdered resin

[0063] First, put the above-mentioned raw materials except the binder into the mixer and stir evenly, then put the evenly stirred material into the wheel mill, then add the binder made of modified polymer and powdery resin, and knead for 20 minutes to produce The material is squeezed into a mud section with a mud extruder, and the mud s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com