Multilayer structure polymer and resin composition together with acrylic rsin film material, acrylic resin laminate film, photocurable acrylic resin film or sheet, laminate film or sheet and laminate

一种聚合物、膜状物的技术,应用在合成树脂层状产品、分层产品、化学仪器和方法等方向,能够解决耐成形白化性差、耐回光性达不到、未记载耐回光性等问题,达到耐白化性优良、满足耐擦伤性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

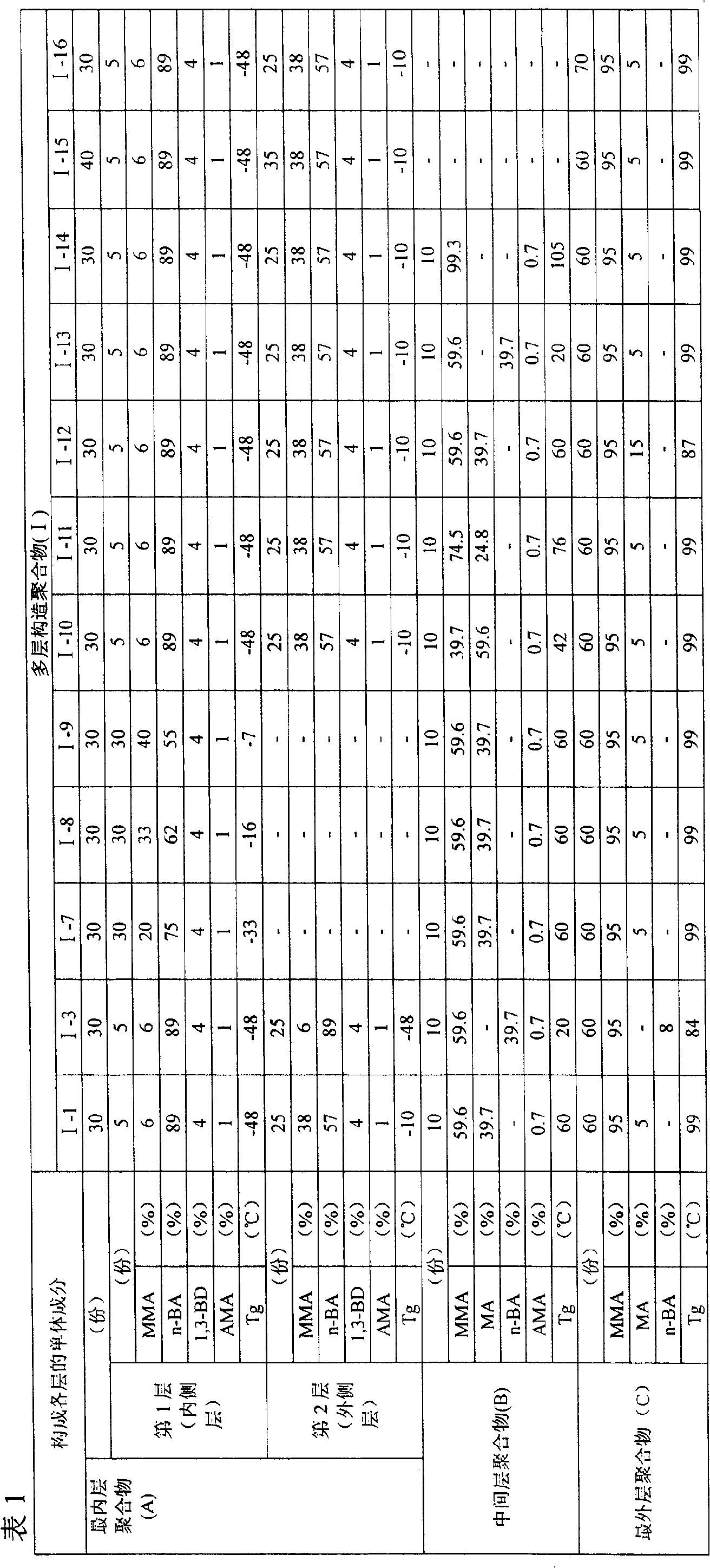

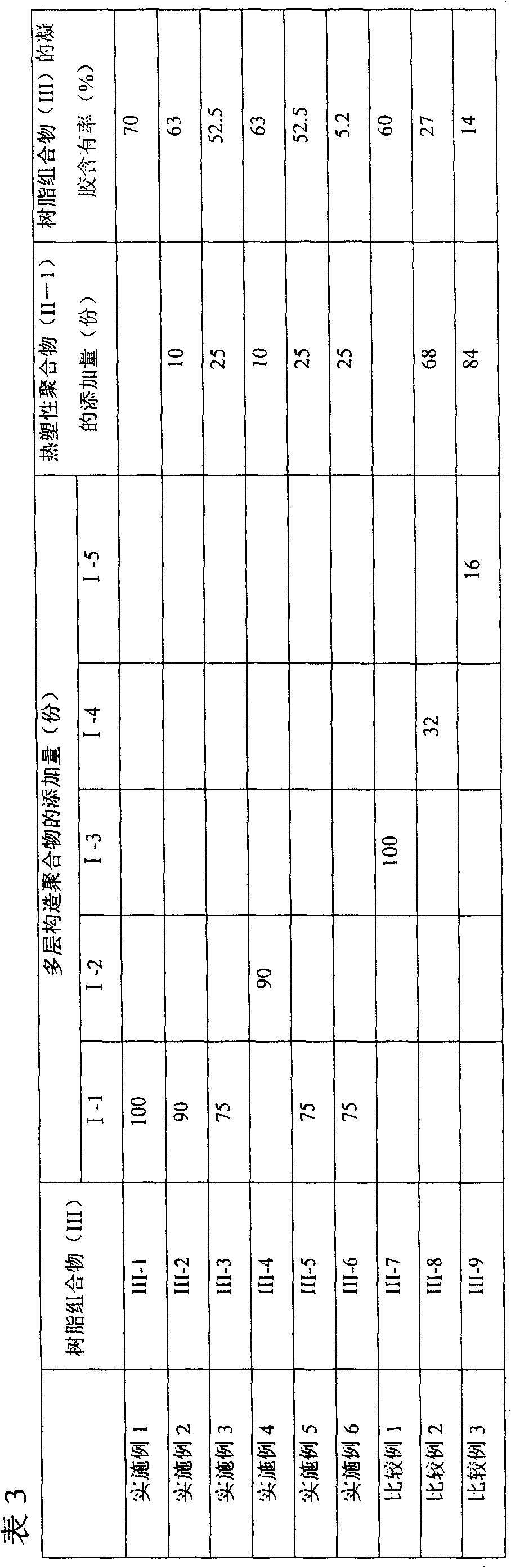

[0781] To 100 parts of the multilayer structure polymer (I-1), 2.7 parts of the product name "Chiubin 234" manufactured by Chiba Special Chemicals Co., Ltd. and 0.1 part of the product name "Adecastab AO-50" manufactured by Asahi Denka Kogyo Co., Ltd. were added as compounding agents. and 0.3 part of the product name "Adecastab LA-57" manufactured by Asahi Denka Co., Ltd., and mixed with a Henschel mixer. This mixture [resin composition (III-1)] was heated to 230°C, supplied to a degassing extruder (PCM-30 (trade name) manufactured by Ikegai Iron Works Co., Ltd.), and kneaded to obtain pellets. .

[0782] The granules produced by the above method are dried at 80°C - day and night, with a 40mm φ non-bending screw extruder (L / D=26) equipped with a 300mm wide T-die, at a barrel temperature of 180-240°C, T Film formation was carried out at a mold temperature of 240° C. to obtain an acrylic resin film (A) having a thickness of 125 μm. Formation of the decorative layer (B) was goo...

Embodiment 2

[0784] In addition to using 90 parts of multilayer structure polymer (I-1) and thermoplastic polymer (II-1) [MMA / MA=99 / 1 (mass ratio), reduced viscosity ηsp / c=0.06L / g] instead of 10 parts Except for 100 parts of the multilayer structure polymer (I-1), a mixture [resin composition (III-2)] was obtained in the same manner as in Example 1, and a film was formed to obtain an acrylic resin film (A). Formation of the decorative layer (B) was good, and there were few printing omissions.

Embodiment 3

[0786] Except using 75 parts of multilayer construction polymers (I-1) and 25 parts of thermoplastic polymers (II-1) to replace 100 parts of multilayer construction polymers (I-1), the mixture [resin Composition (III-3)] was formed into a film to obtain an acrylic resin film (A). Formation of the decorative layer (B) was good, and there were few printing omissions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glossiness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com