Double-end inserting expansion meshing body pile connecting end plate and prefab

An inflatable and integrated technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of complex manufacturing molds and processes, slow butt-joint piles, and high processing costs, and achieve high work efficiency and fast butt joints. Pile, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

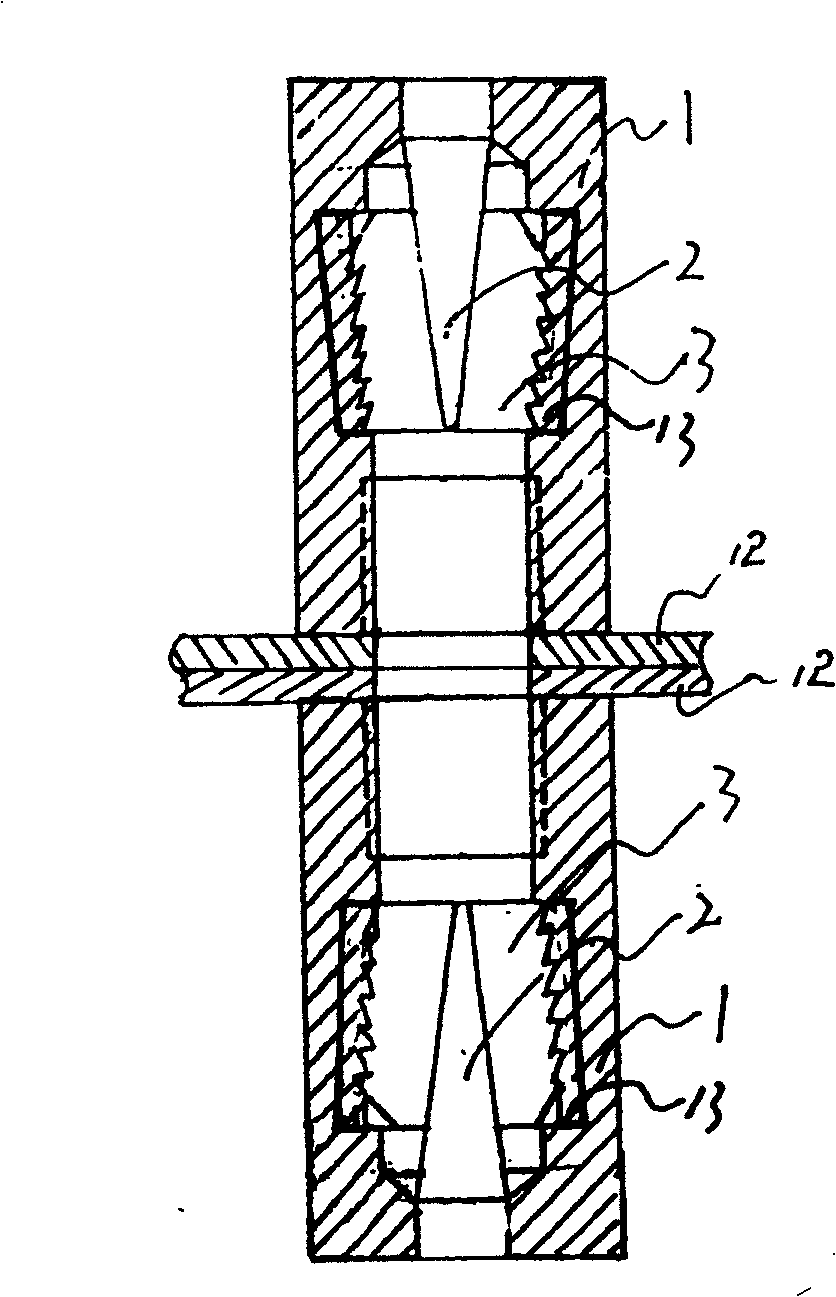

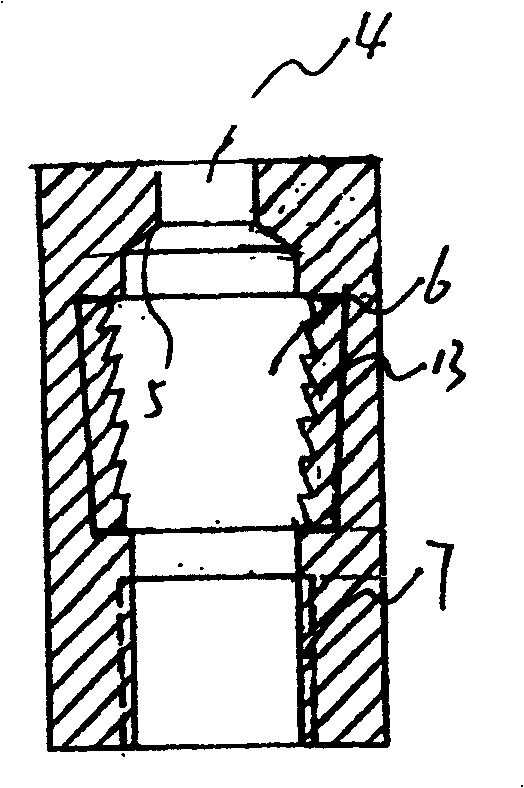

[0017] Embodiment 1: with reference to attached Figure 1~5 . The double ends are inserted into the pile end plate of the expansion engagement body, which includes an end plate 12, two or more expansion nuts 1 are distributed (welded) on the end plate 12, and the expansion engagement tooth sleeve 13 is located at the top of the expansion nut 1. In the expansion cavity 6, when docking, the expansion body of the double-ended expansion engagement body 3 is expanded and engaged in the expansion engagement tooth sleeve 13 in the expansion nut 1 under the action of the expansion pin 2, see the attached figure 1 . Tension nut 1 adopts metal (as steel, stainless steel, alloy steel etc.) or non-metallic material (as plastics, synthetic plastics, pottery etc.) to make by existing casting or injection molding or pottery firing or machining technology. The inner side of the opening of the expansion nut 1 is a strong wire buckle 7, and the center of the bottom of the cap is provided with...

Embodiment 2

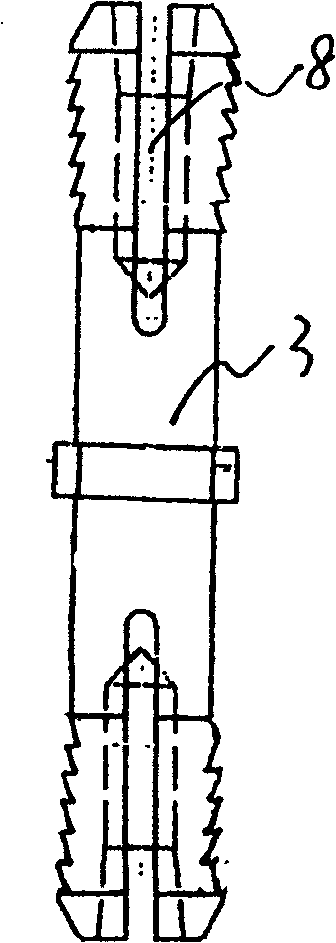

[0018] Embodiment 2: with reference to attached Figure 6 . On the basis of Embodiment 1, the prefabricated part (pipe pile---round tubular, square pipe pile, etc.) composed of double ends inserted into the pile end plate of the expansion meshing body, the two ends of the prefabricated part 10 are respectively equipped with multiple The piling end plate 12 of a stretching nut 1, the headers 11 at both ends of several longitudinal steel bars in the prefabricated part 10 are respectively clamped on the steel bar heading clamping table 5 in the stretching nut 1, and the double ends are expanded and meshed. Body 3 is used for butt joint between two preforms. The expansion of the double-ended expansion engagement body 4 is in the expansion engagement tooth sleeve in the tension nut 1 . (when the double-ended expansion body 3 is docked with the pipe pile, the expansion body in the double-ended expansion body expands in the tension nut 1; when the pipe pile and the pipe pile are no...

Embodiment 3

[0019] Embodiment 3: with reference to attached Figure 7 . On the basis of Examples 1 and 2, the pile connection structure between the pipe pile and the pipe pile, or between the bridge pier and the bridge pier, or between the utility pole and the utility pole, which is formed by inserting the double ends into the expansion engagement body pile connection end plate, the butt joint The ends of the two prefabricated parts are respectively equipped with pile connection end plates with a plurality of tension nuts. The openings of the pulling nuts are opposite, and the double-headed expansion engagement bodies are respectively expanded in the expansion engagement tooth sleeves in the expansion nuts through the expansion pins to complete the butt joint between the prefabricated parts and the prefabricated parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com