Oil-gas spring

A technology of oil and gas springs and driving springs, applied in springs/shock absorbers, elastic suspensions, gas-liquid shock absorbers, etc., can solve the problems of increased design, gas leakage, and small piston extension strokes, and achieves manufacturing and maintenance. Convenience, impact reduction, and the effect of extending the inflation interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

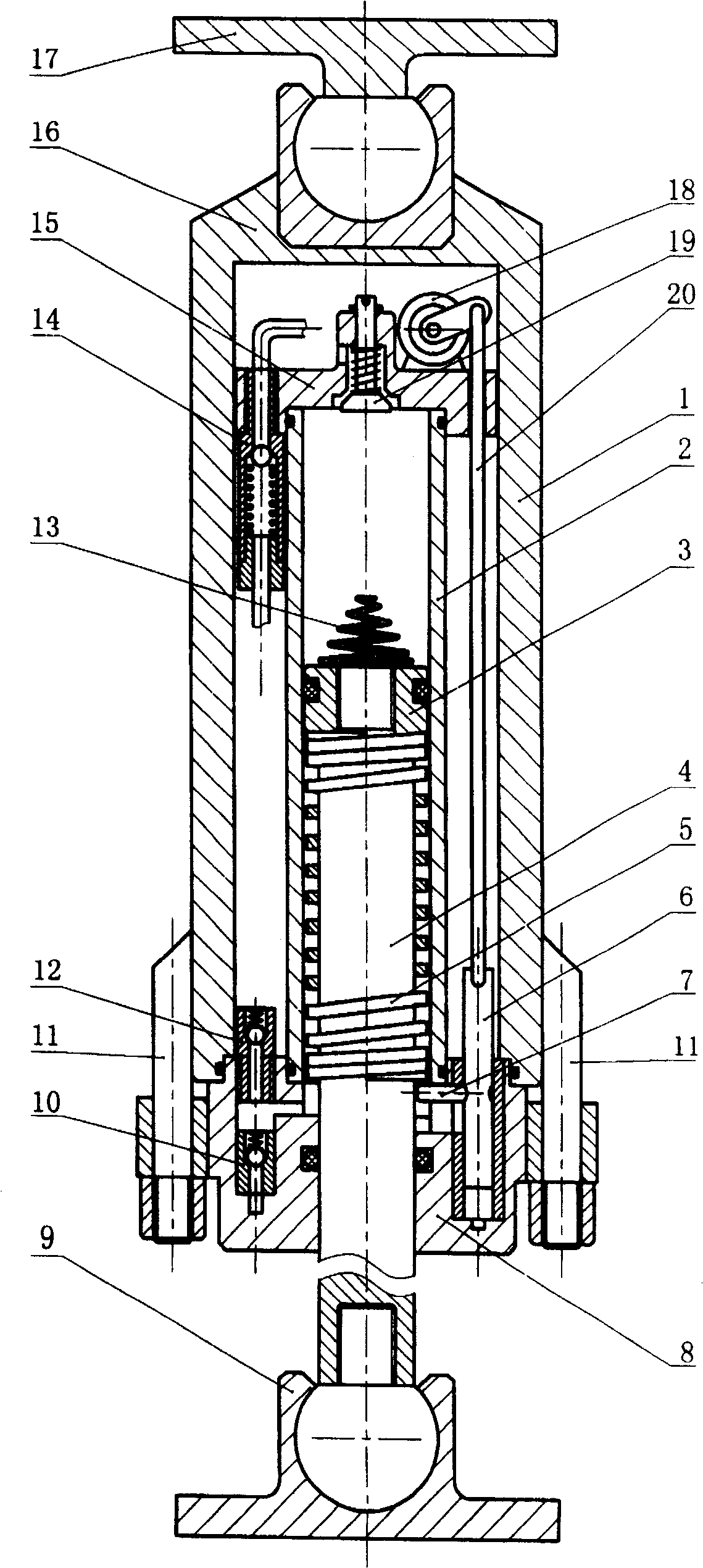

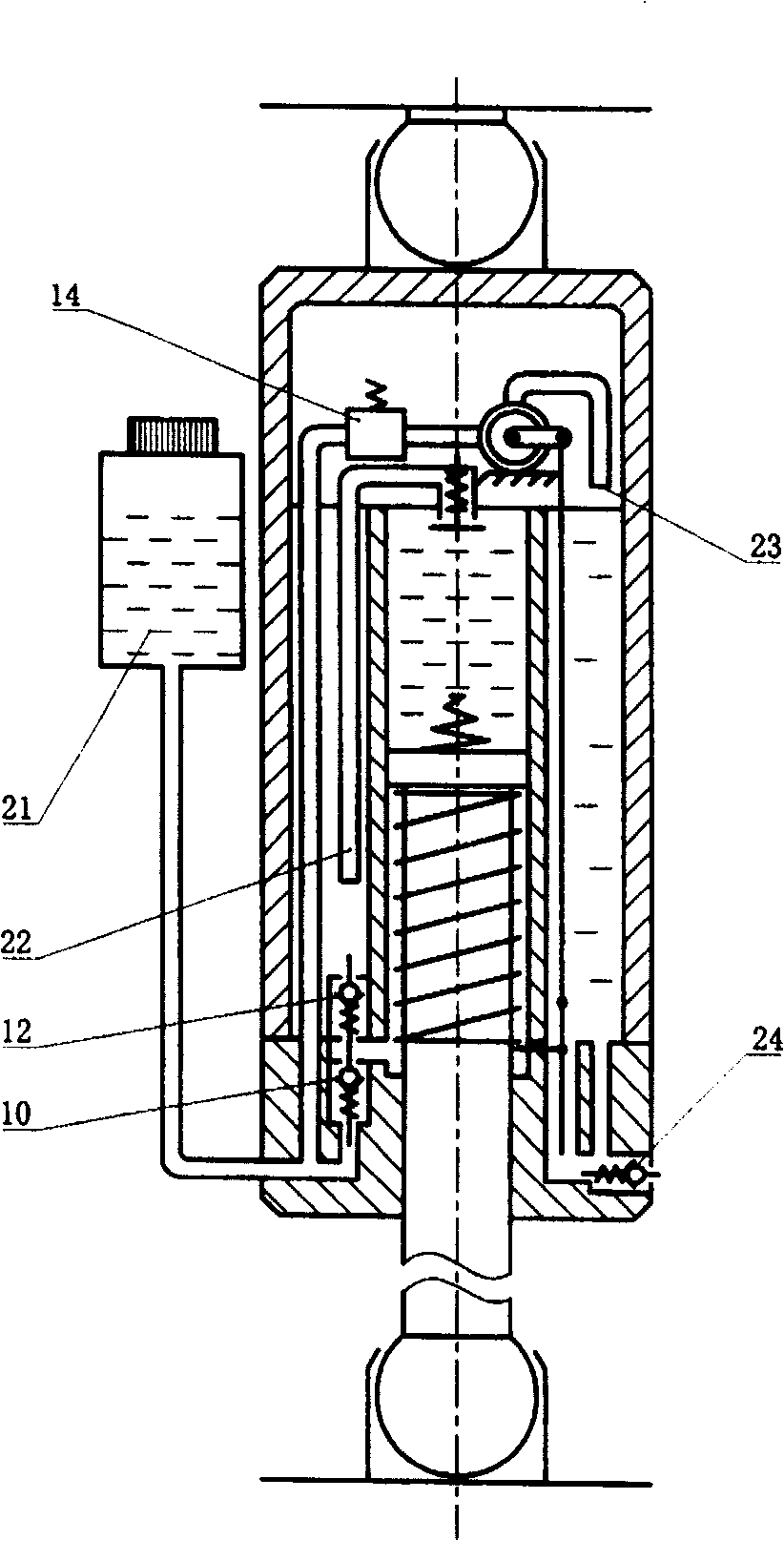

[0019] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

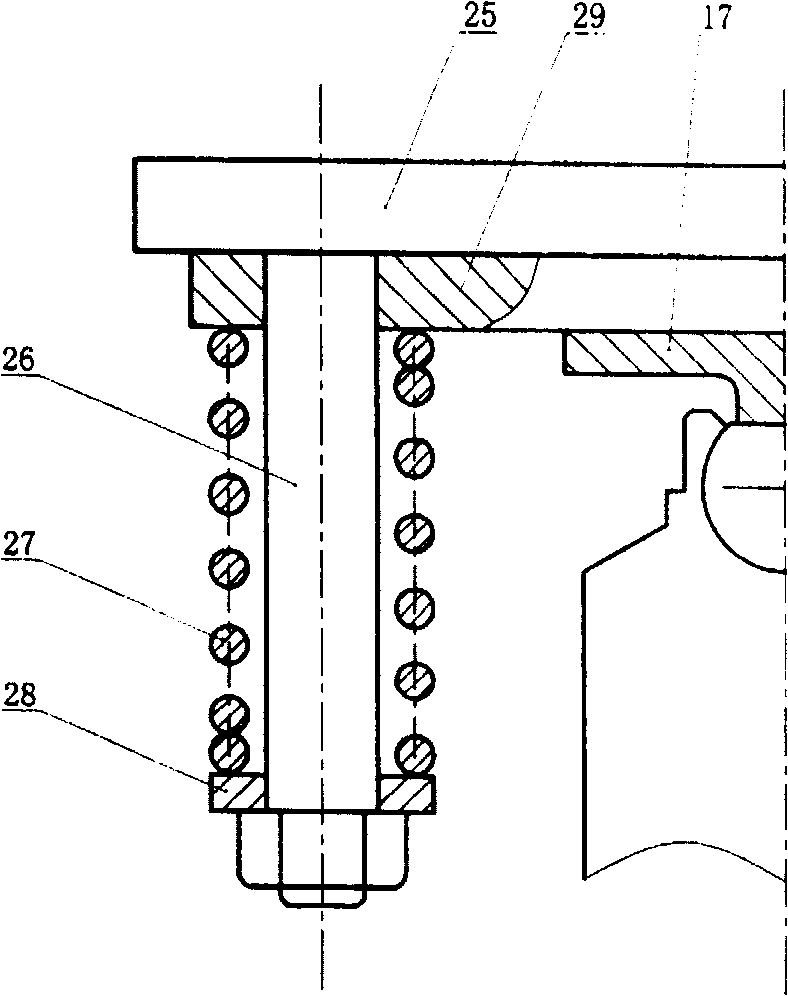

[0020] The outer cylinder barrel 1 is used as a container for storing oil and high-pressure gas, and is used as a casing at the same time, and its upper end is sealed by an outer cylinder cover 16 by welding or other means. The upper end of the outer cylinder head 16 is connected to the vehicle frame through the upper spherical hinge plate 17, the lower end of the outer cylinder 1 is socketed with the base 8 at the open end, and there is a sealing ring in between, and the outer cylinder 1 and the base 8 are pulled together by bolts 11. Tight fix. The inner cylinder 2 is used as the working cylinder for pushing the oil, and it is set inside the outer cylinder 1. The upper end is pressed by the inner cylinder head 15, and there is a sealing ring in between, and the lower end is socketed with the base 8, and there is a sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com