Refrigerator system for store

A technology for refrigerators and shops, applied in the direction of refrigerators, refrigerators, household refrigeration devices, etc., can solve the problems of amplifying and amplifying vibration and noise, and achieve the effect of stabilizing the exhaust gas temperature, reducing vibration and noise, and reducing restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

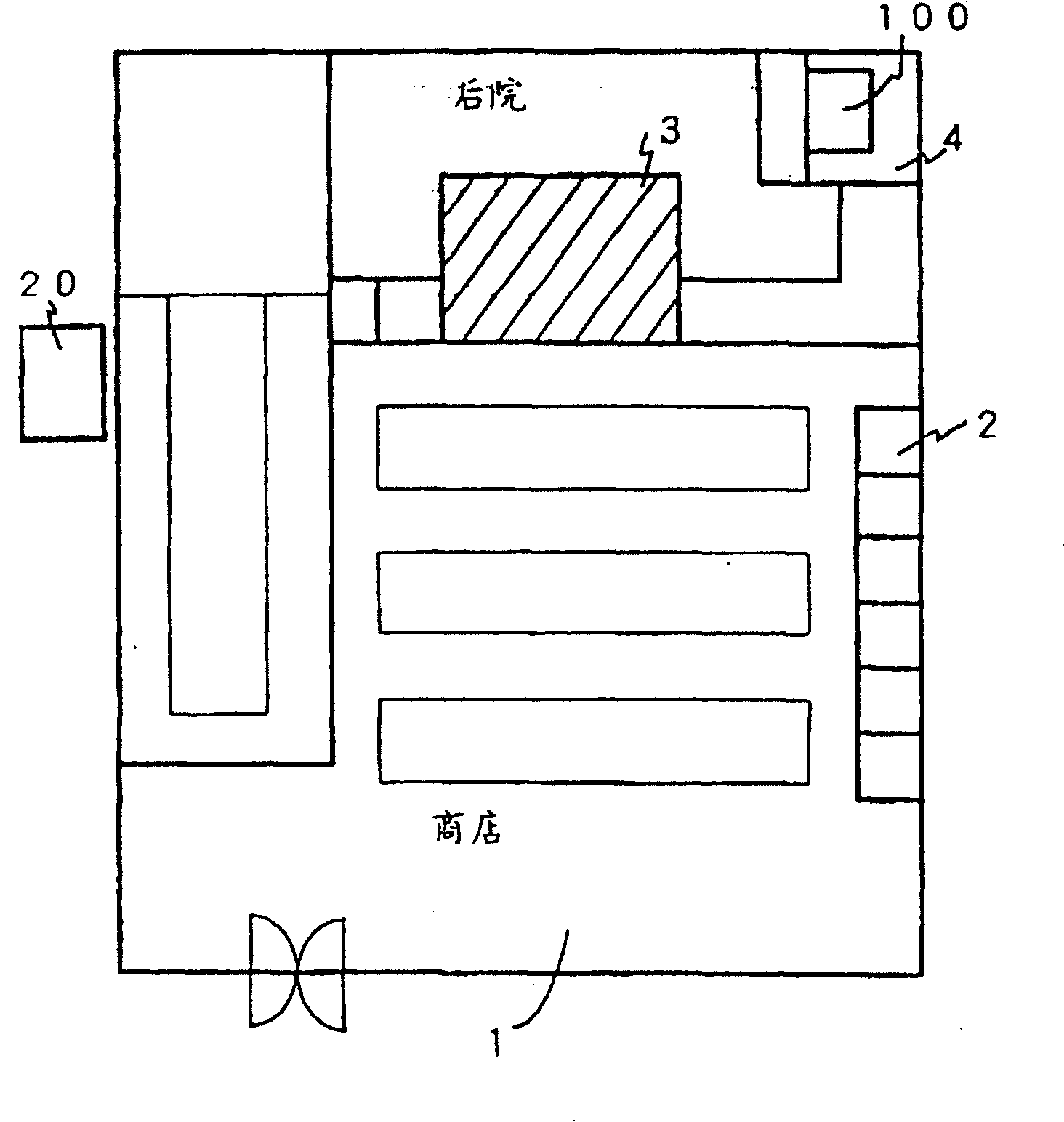

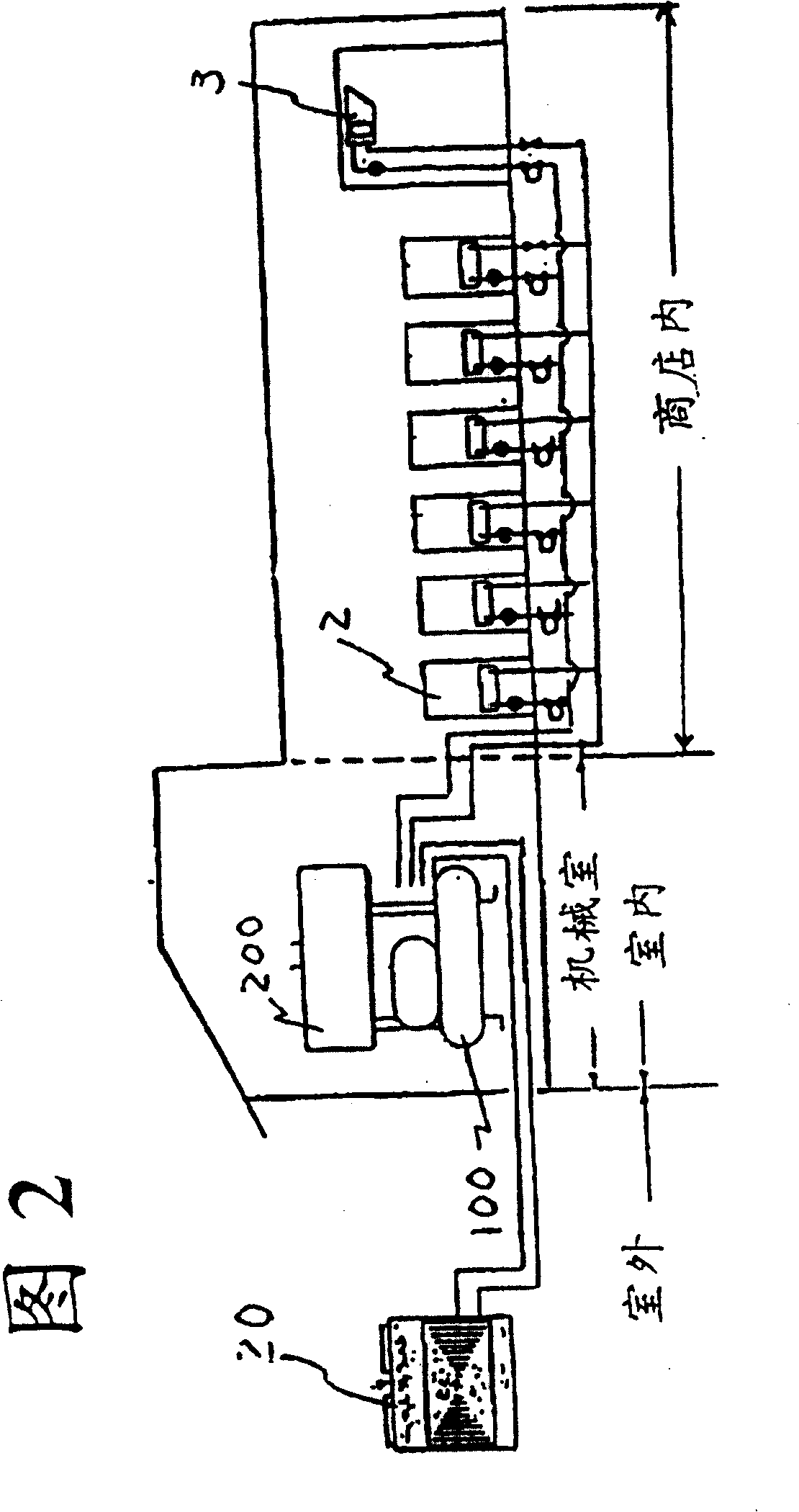

[0029] Some concepts of the invention can be summarized as follows.

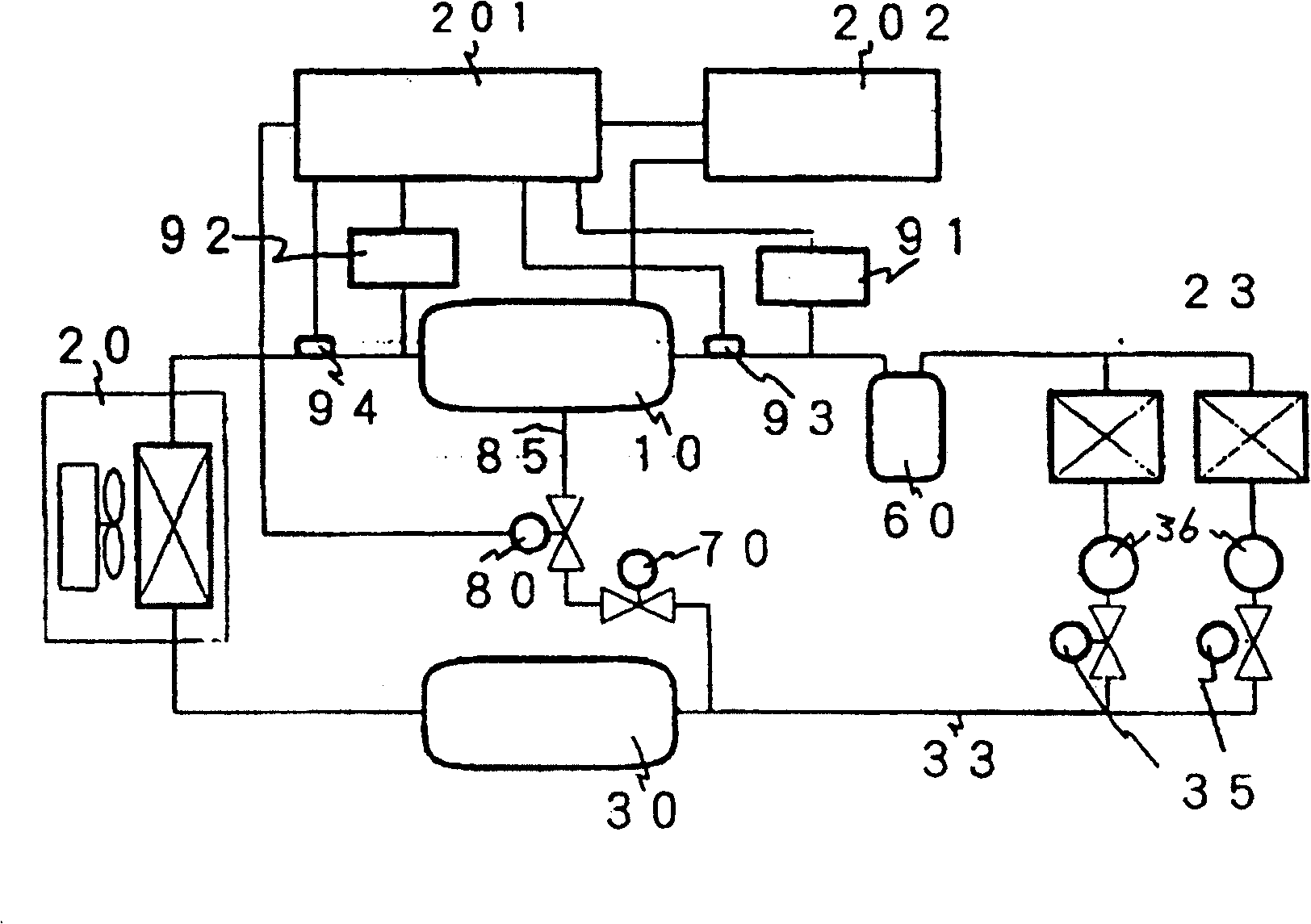

[0030] (1) A screw compressor without reciprocating motion is used. Its driving method is to control its rotational speed by detecting the operating suction pressure and changing the converter frequency. It is installed in a special mechanical room.

[0031] (2) Control the liquid injection amount corresponding to the discharge gas temperature and pressure value of the screw compressor, inject the liquid refrigerant into a compression chamber near the discharge port, and during one rotation movement of the rotating spiral cladding of the screw compressor, connected to each other once.

[0032] (3) The inventive refrigerant system can discriminate a malfunction, such as an abnormal rise in inverter temperature, and can connect the power supply of the screw compressor to a commercial power supply when such a malfunction occurs.

[0033] (4) providing a mode of operating the compressor at a fixed speed; and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com